6.10 Troubleshooting without Fault Display

292 YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual

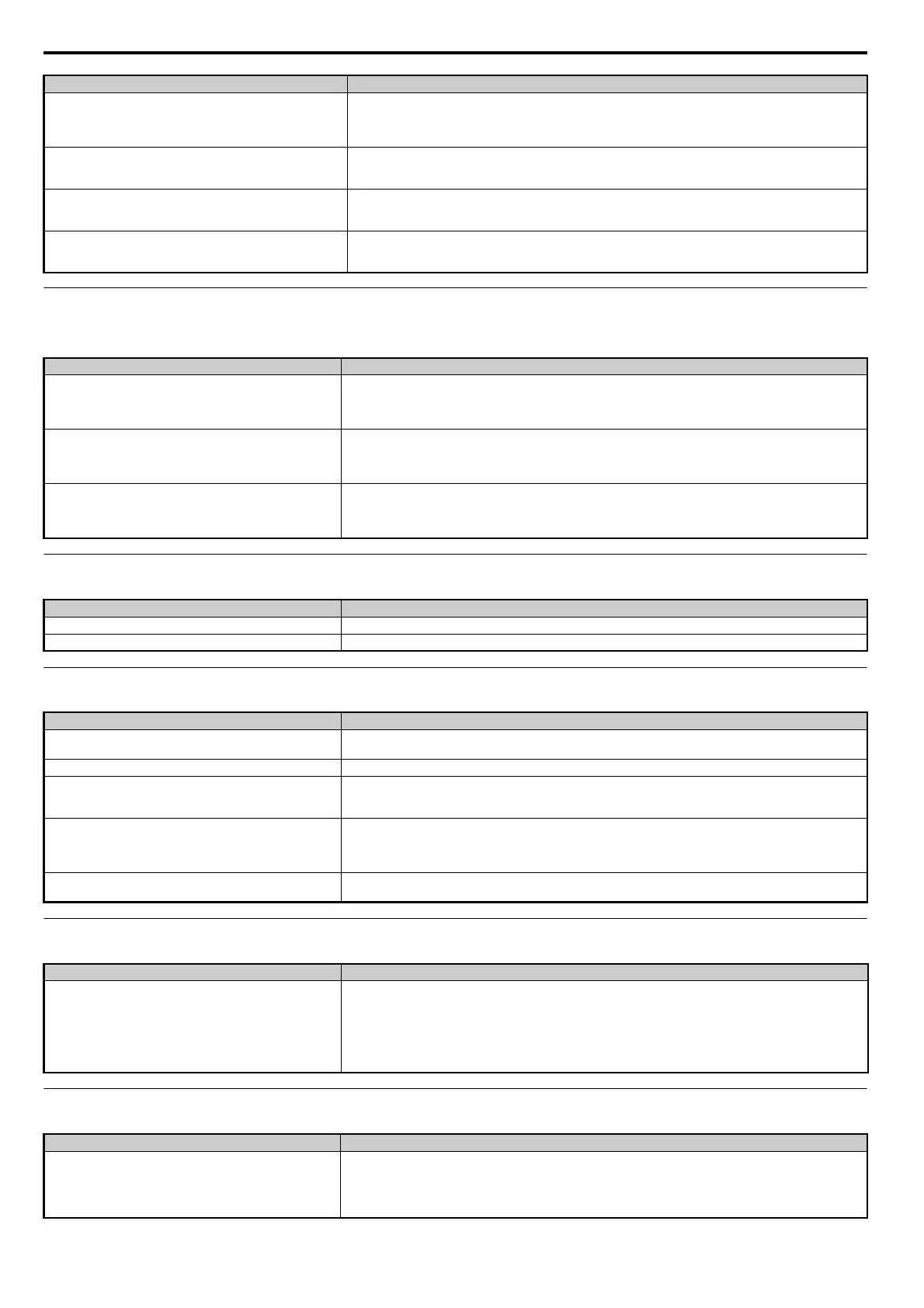

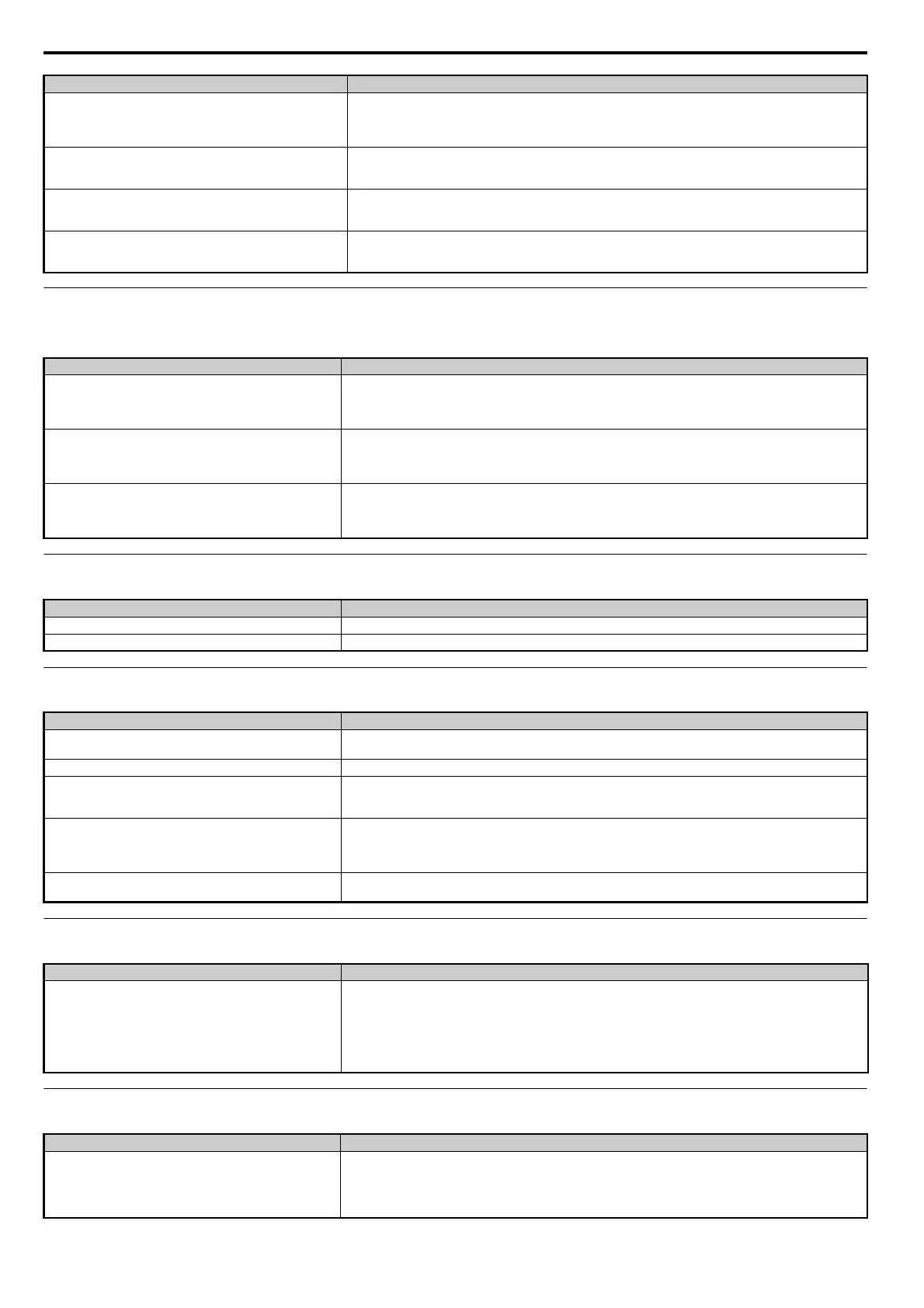

◆ Drive Frequency Reference Differs from the Controller Frequency Reference

Command

◆ Excessive Motor Oscillation and Erratic Rotation

◆ Deceleration Takes Longer Than Expected with Dynamic Braking Enabled

◆ Noise From Drive or Motor Cables When the Drive is Powered On

◆ Earth Leakage Circuit Breaker (ELCB) Trips During Run

Incorrect frequency reference setting.

• Check the multi-function analog input settings. Multi-function analog input terminal A1, A2, or A3 is set for

frequency gain (H3-02, H3-10, or H3-06 is set to “1”), but there is no voltage or current input provided.

• Make sure H3-02, H3-10, and H3-06 are set to the proper values.

• See if the analog input value is set to the right value (U1-13 to U1-15).

The Stall Prevention level during acceleration and deceleration set

too low.

• Check the Stall Prevention level during acceleration (L3-02).

• If L3-02 is set too low, acceleration may be taking too long.

• Increase L3-02.

The Stall Prevention level during run has been set too low.

• Check the Stall Prevention level during run (L3-06).

• If L3-06 is set too low, speed will drop as the drive outputs torque.

• Increase the setting value.

Drive reached the limitations of the V/f motor control method.

• The motor cable may be long enough (over 50 m) to require Auto-Tuning for line-to-line resistance.

• Be aware that V/f Control is comparatively limited when it comes to producing torque at low speeds.

• Consider switching to Open Loop Vector Control.

Cause Possible Solutions

The analog input gain and bias for the frequency reference input

are set to incorrect values.

• Check the gain and bias settings for the analog inputs that are used to set the frequency reference. Check parameters

H3-03 and H3-04 for input A1, check parameters H3-11 and H3-12 for input A2, and check parameters H3-07 and

H3-08 for input A3.

• Set these parameters to the appropriate values.

A frequency bias signal is being entered via analog input terminals

A1 to A3.

• If more than one of multi-function analog inputs A1 to A3 is set for frequency reference bias (H3-02, H3-10, or H3-06

is set to “0”), then the sum of all signals builds the frequency reference.

• Make sure that H3-02, H3-10, and H3-06 are set appropriately.

• Check the input level set for terminals A1 to A3 (U1-13 to U1-15).

PI control is enabled, and the drive is consequently adjusting the

output frequency to match the PI setpoint. The drive will only

accelerate to the maximum output frequency set in E1-04 while PI

control is active.

If PI control is not necessary for the application, disable it by setting b5-01 to “0”.

Cause Possible Solutions

Poor balance between motor phases. Check drive input power voltage to ensure that it provides stable power.

Hunting prevention function is disabled. Enable Hunting Prevention (n1-01 = 1).

Cause Possible Solutions

L3-04 is set incorrectly.

• Check the Stall Prevention level during deceleration (L3-04).

• If a dynamic braking option has been installed, disable Stall Prevention during deceleration (L3-04 = 0).

The deceleration time is set too long. Set deceleration to more appropriate time (C1-02).

Insufficient motor torque.

• Assuming parameter settings are normal and that no overvoltage occurs when there is insufficient torque, it is likely

that the demand on the motor has exceeded the motor capacity.

• Use a larger motor.

Reaching the torque limit.

• If multi-function analog input terminal A1, A2, or A3 is set to torque limit (H3-02, H3-10, or H3-06 equals 10, 11, 12,

or 15), ensure that the analog input levels are set to the correct levels.

• Ensure H3-02, H3-10, and H3-06 are set to the right levels.

• Ensure the analog input is set to the correct value (U1-13 to U1-15).

Load exceeded the internal torque limit determined by the drive

rated current.

Switch to a larger capacity drive.

Cause Possible Solutions

Relay switching in the drive generates excessive noise.

• Lower the carrier frequency (C6-02).

• Install a noise filter on the input side of drive input power.

• Install a noise filter on the output side of the drive.

• Place the wiring inside a metal conduit to shield it from switching noise.

• Ground the drive and motor properly.

• Separate the main circuit wiring and the control lines.

• Make sure wires and the motor have been properly grounded.

Cause Possible Solutions

Excessive leakage current trips ELCB.

• Increase the ELCB sensitivity or use ELCB with a higher threshold.

• Lower the carrier frequency (C6-02).

• Reduce the length of the cable used between the drive and the motor.

• Install a noise filter or reactor on the output side of the drive. Set the carrier frequency to 2 kHz when connecting a

reactor.

Cause Possible Solutions

SIEP_C710616_35.book 292 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...