6.5 Alarm Detection

YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual 275

6.5 Alarm Detection

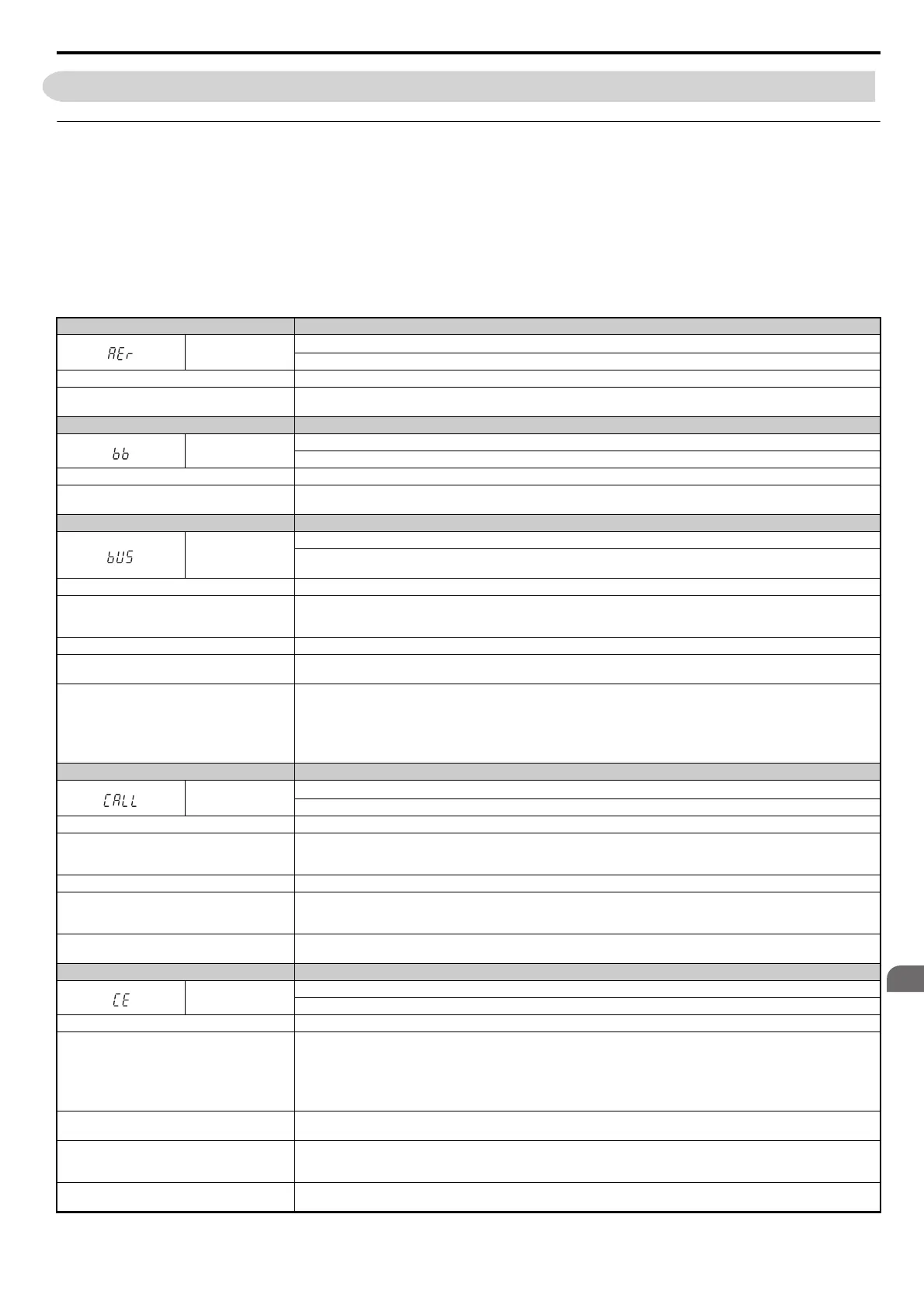

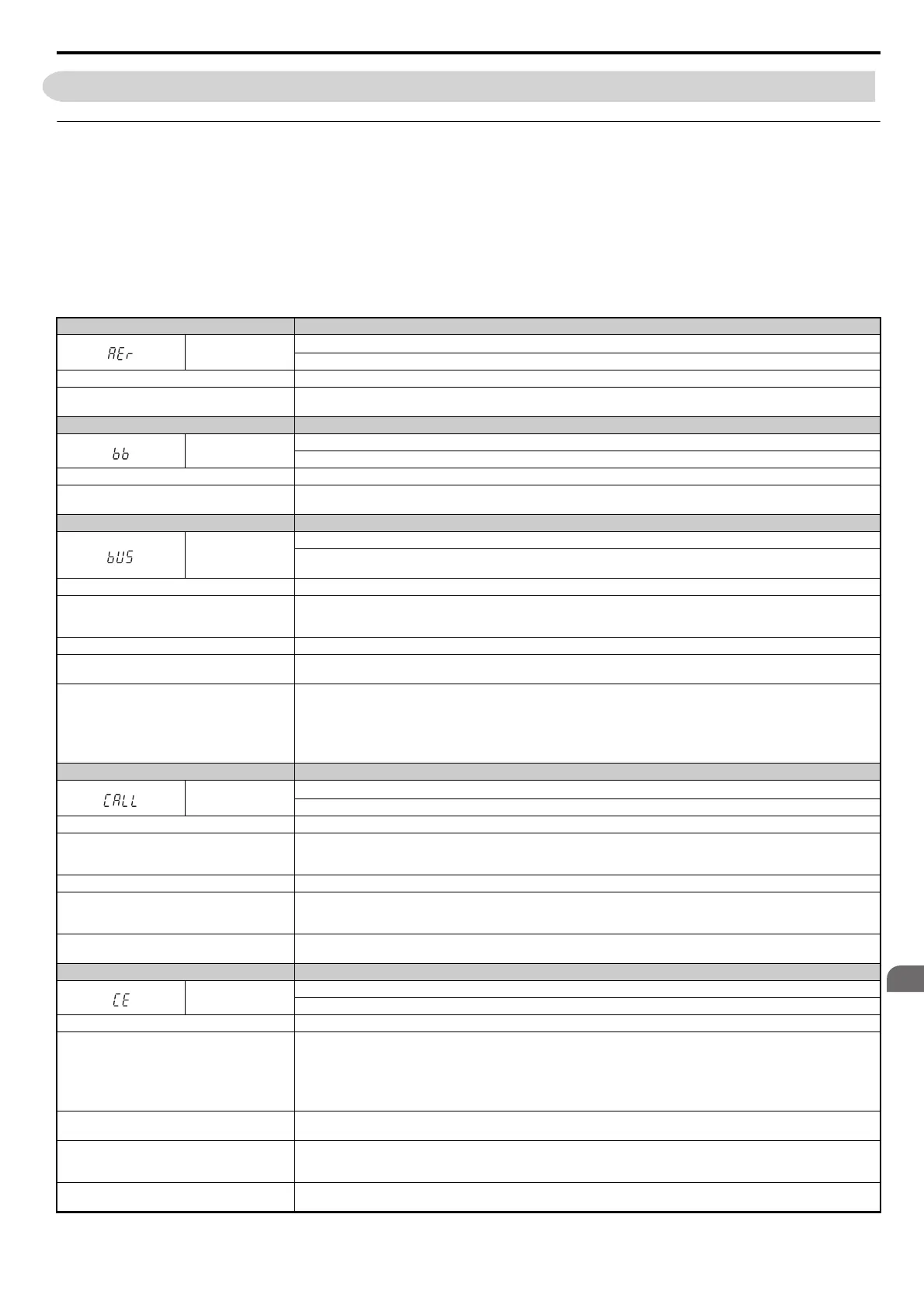

◆ Alarm Codes, Causes, and Possible Solutions

Alarms are drive protection functions that do not necessarily cause the drive to stop. Once the cause of an alarm is

removed, the drive will return to the same status is was before the alarm occurred.

When an alarm has been triggered, the ALM light on the digital operator display blinks and the alarm code display

flashes. If a multi-function output is set for an alarm (H2- = 10), that output terminal will be triggered.

Note: If a multi-function output is set to close when an alarm occurs (H2- = 10), it will also close when maintenance periods are

reached, triggering alarms LT-1 through LT-4 (triggered only if H2- = 2F).

Table 6.11 Alarm Codes, Causes, and Possible Solutions

Digital Operator Display Minor Fault Name

AEr

Communication Option Station Number Setting Error (CC-Link, CANopen, MECHATROLINK-II)

Option card node address is outside the acceptable setting range.

Cause Possible Solutions

Station number is set outside the possible setting

range.

• Set parameter F6-10 to the proper value if a CC-Link option card is used.

• Set parameter F6-35 to the proper value if a CANopen option card is used.

Digital Operator Display Minor Fault Name

bb

Baseblock

Drive output interrupted as indicated by an external baseblock signal.

Cause Possible Solutions

External baseblock signal was entered via one of the

multi-function input terminals (S1 to S8).

Check external sequence and baseblock signal input timing.

Digital Operator Display Minor Fault Name

bUS

Option Communication Error

• After initial communication was established, the connection was lost.

• Assign a Run command frequency reference to the option card.

Cause Possible Solutions

Connection is broken or master controller stopped

communicating.

• Check for faulty wiring.

• Correct the wiring.

• Check for disconnected cables and short circuits. Repair as needed.

Option card is damaged. If there are no problems with the wiring and the fault continues to occur, replace the option card.

The option card is not properly connected to the

drive.

• The connector pins on the option card are not properly lined up with the connector pins on the drive.

• Reinstall the option card.

A data error occurred due to noise.

• Check options available to minimize the effects of noise.

• Take steps to counteract noise in the control circuit wiring, main circuit lines and ground wiring.

• Try to reduce noise on the controller side.

• Use surge absorbers on magnetic contactors or other equipment causing the disturbance.

• Use recommended cables or some other type of shielded line. Ground the shield to the controller side or on the input power side.

• All wiring for comm. devices should be separated from drive input power lines. Install an EMC noise filter to the drive input power.

Digital Operator Display Minor Fault Name

CALL

Serial Communication Transmission Error

Communication has not yet been established.

Cause Possible Solutions

Communications wiring is faulty, there is a short

circuit, or something is not connected properly.

• Check for wiring errors.

• Correct the wiring.

• Check for disconnected cables and short circuits. Repair as needed.

Programming error on the master side. Check communications at start-up and correct programming errors.

Communications circuitry is damaged.

• Perform a self-diagnostics check.

• If the problem continues, replace either the control board or the entire drive. For instructions on replacing the control board, contact

Yaskawa or your nearest sales representative.

Termination resistor setting is incorrect.

A termination resistor must be installed at both ends of a communication line. Slave drives must have the internal termination resistor

switch set correctly. Place DIP switch S2 to the ON position.

Digital Operator Display Minor Fault Name

CE

MEMOBUS/Modbus Communication Error

Control data was not received correctly for two seconds.

Cause Possible Solutions

A data error occurred due to noise.

• Check options available to minimize the effects of noise.

• Take steps to counteract noise in the control circuit wiring, main circuit lines, and ground wiring.

• Reduce noise on the controller side.

• Use surge absorbers for the magnetic contactors or other components that may be causing the disturbance.

• Use only recommended shielded line. Ground the shield on the controller side or on the drive input power side.

• Separate all wiring for comm. devices from drive input power lines. Install an EMC noise filter to the drive input power supply.

Communication protocol is incompatible.

• Check the H5 parameter settings as well as the protocol setting in the controller.

• Ensure settings are compatible.

The CE detection time (H5-09) is set shorter than the

time required for a communication cycle to take

place.

• Check the PLC.

• Change the software settings in the PLC.

• Set a longer CE detection time (H5-09).

Incompatible PLC software settings or there is a

hardware problem.

• Check the PLC.

• Remove the cause of the error on the controller side.

SIEP_C710616_35.book 275 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...