6.10 Troubleshooting without Fault Display

YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual 293

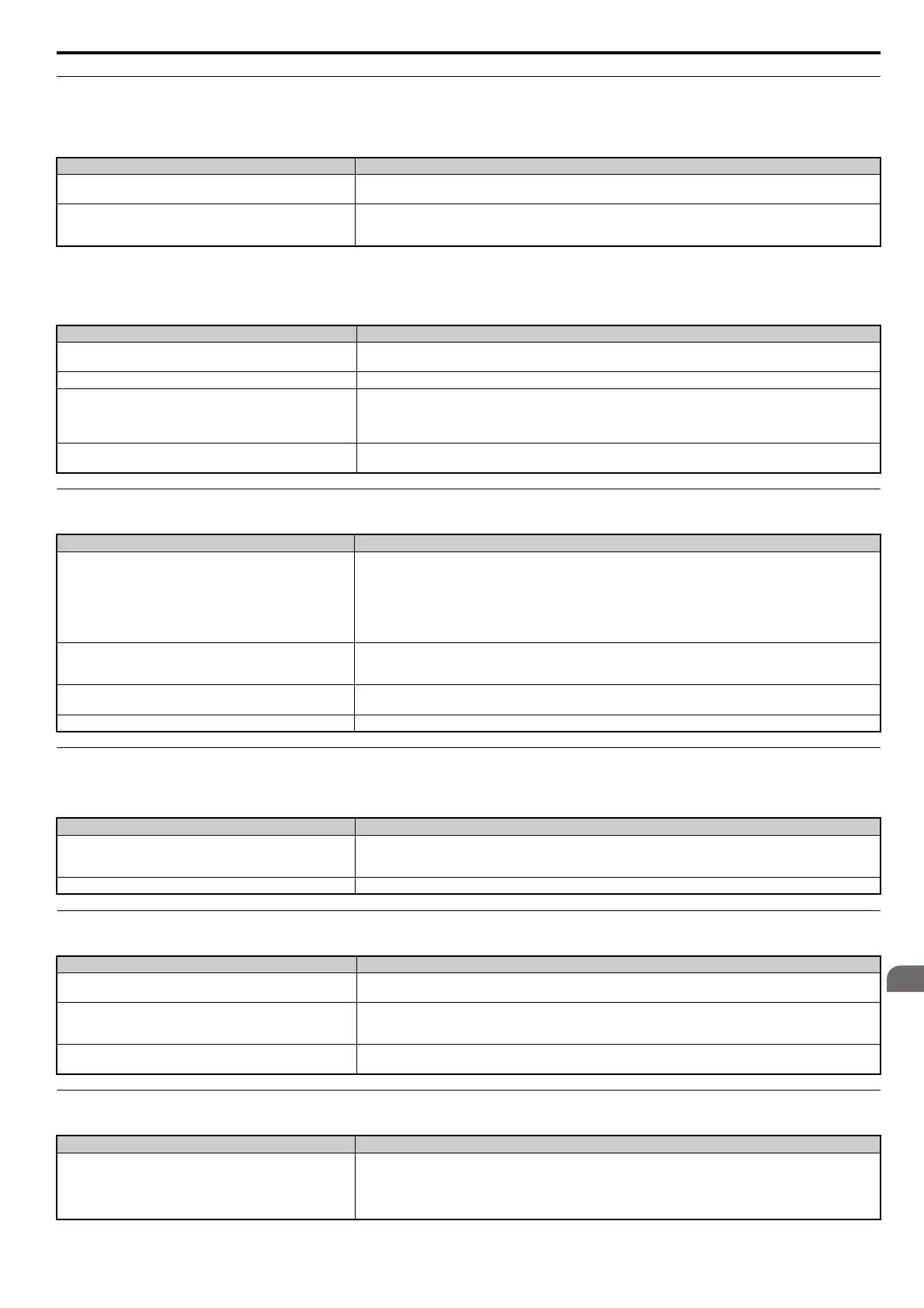

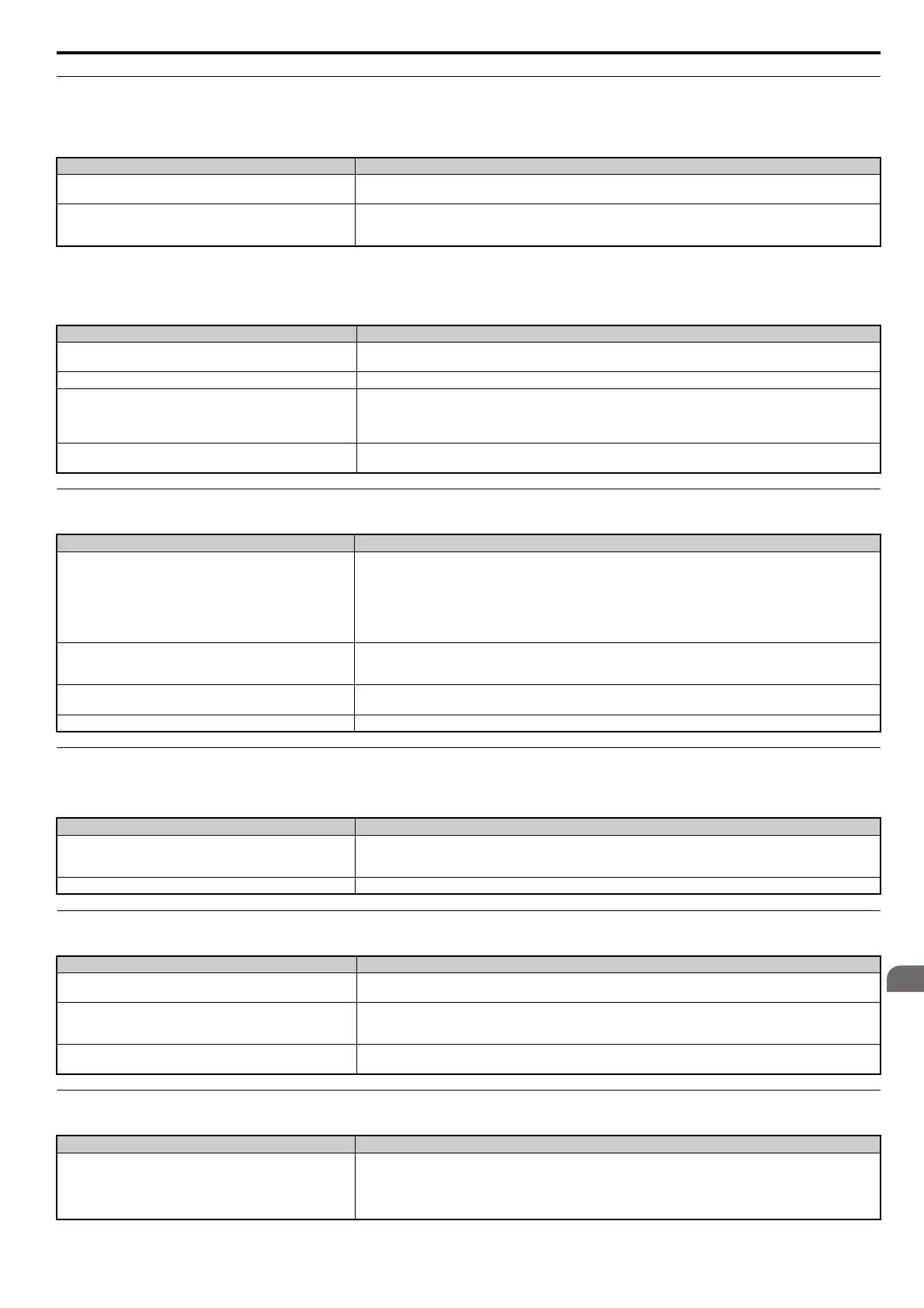

◆ Connected Machinery Vibrates When Motor Rotates

■ Unexpected Noise from Connected Machinery

Note: The drive may have trouble assessing the status of the load due to white noise generated from using Swing PWM (C6-02 = 7 to A).

■ Oscillation or Hunting

◆ PI Output Fault

◆ Motor Rotates After the Drive Output is Shut Off (Motor Rotates During DC Injection

Braking)

◆ Output Frequency is not as High as Frequency Reference

◆ Buzzing Sound from Motor at 2 kHz

Cause Possible Solutions

The carrier frequency is at the resonant frequency of the connected

machinery.

Adjust the carrier frequency using parameters C6-02 through C6-05.

The drive output frequency is the same as the resonant frequency

of the connected machinery.

• Adjust the parameters used for the Jump frequency function (d3-01 through d3-04) to skip the problem-causing

bandwidth.

• Place the motor on a rubber pad to reduce vibration.

Cause Possible Solutions

Insufficient tuning.

Perform Auto-Tuning.

Refer to Motor Performance Fine-Tuning on page 258.

Gain is too low when using PI control. Refer to b5: PI Control on page 145 for details.

The frequency reference is assigned to an external source and the

signal is noisy.

• Ensure that noise is not affecting the signal lines.

• Separate main circuit wiring and control circuit wiring.

• Use twisted-pair cables or shielded wiring for the control circuit.

• Increase the analog input time filter constant (H3-13).

The cable between the drive and motor is too long.

• Perform Auto-Tuning.

• Reduce the length of the cable.

Cause Possible Solutions

No PI feedback input.

• Check the multi-function analog input terminal settings.

• Set multi-function analog input terminal A1, A2, or A3 for PI feedback (H3-02, H3-10, or H3-06 = “B”).

• A signal input to the terminal selection for PI feedback is needed.

• Check the connection of the feedback signal.

• Check the various PI-related parameter settings.

• No PI feedback input to the terminal causes the value detected to be 0, causing a PI fault and the drive to operate at

max frequency.

The level of detection and the target value do not correspond with

each other.

• PI control keeps the difference between target and detection values at 0. Set the input level for the values relative to

one another.

• Use analog input gains H3-03 and H3-11 to adjust PI target and feedback signal scaling.

Reverse drive output frequency and speed detection. When output

frequency rises, the sensor detects a speed decrease.

Set PI output for reverse characteristics (b5-09 = 1).

Adjustment made to PI parameter settings are insufficient. Refer to b5: PI Control on page 145 for details.

Cause Possible Solutions

DC Injection Braking is set too low and the drive cannot decelerate

properly.

• Adjust the DC Injection braking settings.

• Increase the current level for DC Injection Braking (b2-02).

• Increase the DC Injection Braking time at stop (b2-04).

The stopping method is set so that the drive coasts to stop. Set b1-03 (Stopping Method Selection) to 0 or 2.

Cause Possible Solutions

Frequency reference is set within the range of the Jump frequency.

• Adjust the parameters used for the Jump frequency function (d3-01, d3-02, d3-03).

• Enabling the Jump frequency prevents the drive from outputting the frequencies specified in the Jump range.

Upper limit for the frequency reference has been exceeded.

• Set the maximum output frequency and the upper limit for the frequency reference to more appropriate values (E1-

04, d2-01).

• The following calculation yields the upper value for the output frequency = E1-04 × d2-01 / 100

Large load triggered Stall Prevention function during acceleration.

• Reduce the load.

• Adjust the Stall Prevention level during acceleration (L3-02).

Cause Possible Solutions

Exceeded 110% of the rated output current of the drive while

operating at low speeds.

• If the output current rises too high at low speeds, the carrier frequency is automatically reduced and causes a whining

or buzzing sound.

• If the sound is coming from the motor, disable carrier frequency derating (L8-38 = 0).

• Disabling the automatic carrier frequency derating increases the chances of an overload fault (oL2). Switch to a larger

capacity motor if oL2 faults occur too frequently.

SIEP_C710616_35.book 293 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...