82.3-0000010 OM

110

4.4.4 Tow hitch with non-automatic rotating yoke under GOST 32774 and ISO 6489-2

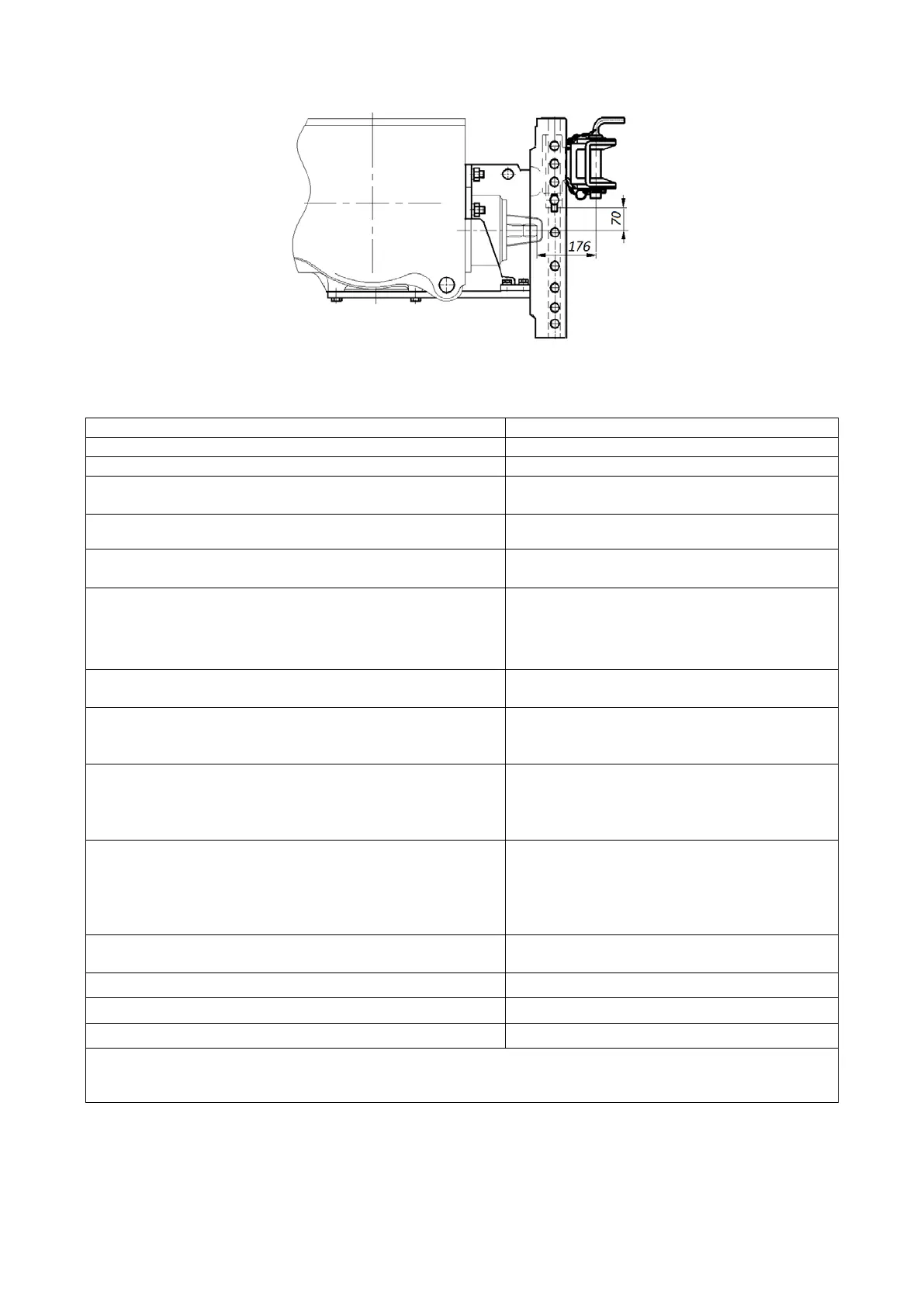

Figure 4.4.3 – Installation scheme of non-automatic rotating yoke (recommended posi-

tion) under GOST 32774 and ISO 6489-2

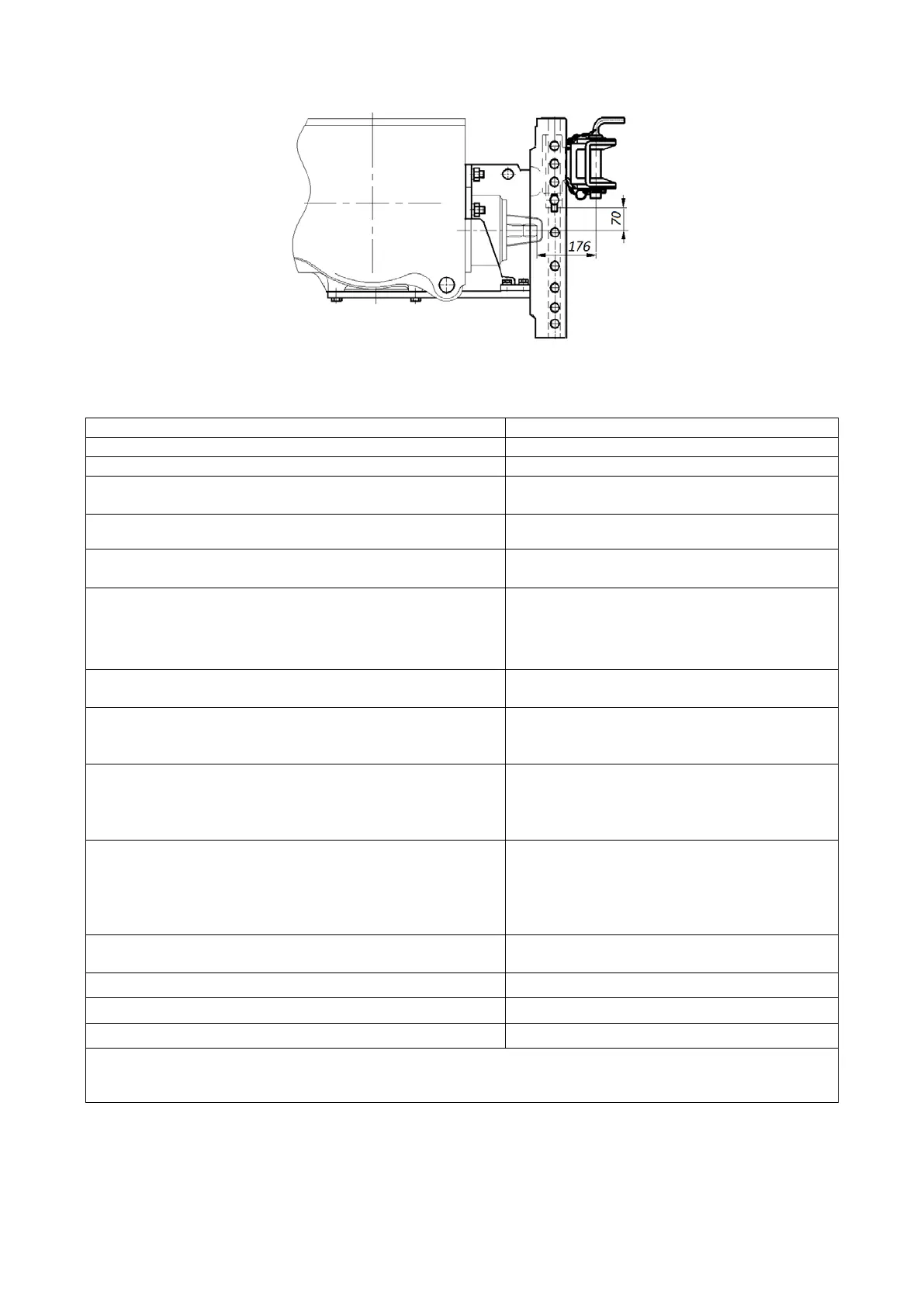

Table 4.4.3 – Basic parameters and coupling dimensions of non-automatic rotating

yoke under GOST 32774 and ISO 6489-2

Non-automatic rotating yoke

Guide grooves of the bracket attached to

rear surface of rear axle body

Non-automatic rotational, height adjustable

1)

For connection of trailers and semi-trailers.

Operation with PTO is not provided.

а) kingpin diameter

b) yoke gap height

c) yoke gap depth from kingpin axis

30

80

55

7 Yoke position

2)

for trailers with standard height of the

draft pole

8 Type of trailing appliance for connection to yoke

Non-rotating hitch eyes in accordance with

GOST 34598-2019, ISO 5692-

9 Vertical load in hitch point, equivalent to weight, kg, not

more than:

- specified on yoke nameplate;

- permissible for the given tractor with yoke

2000

10 Relative calculated value of axial forces (D), kN, not

more than:

- specified on yoke nameplate;

-

permissible with due account for yoke attachment struc-

ture

70.1

43.6

11 Safety device type

11.1 Connection point of safety device to the tractor

Safety chain (rope)

3)

Bores in guide grooves of mounting bracket

e1*2015/208*2018/829ND*00499*00

14 Certificate of Customs Union Technical Regulation, No

1)

The height should be set equal to the height of the trailer eye.

2)

Recommended.

3)

ATTENTION: IT IS FORBIDDEN TO PUT YOKE TO POSITIONS WHERE ITS BODY

JUTS OUT OF THE TOW HITCH BRACKET END (UP OR DOWN) FOR MORE THAN 15 MM!

ATTENTION: TAKING INTO ACCOUNT THE RELATIVE CALCULATED VALUE OF AXI-

AL FORCES (D) PERMISSIBLE FOR THIS ELEMENT, THE MASS OF THE TRAILER, THE

SEMI-TRAILER OR THE MACHINE TO BE ATTACHED TO THE ROTATING YOKE SHALL NOT

EXCEED 12 TONS!

Loading...

Loading...