82.3-0000010 OM

232

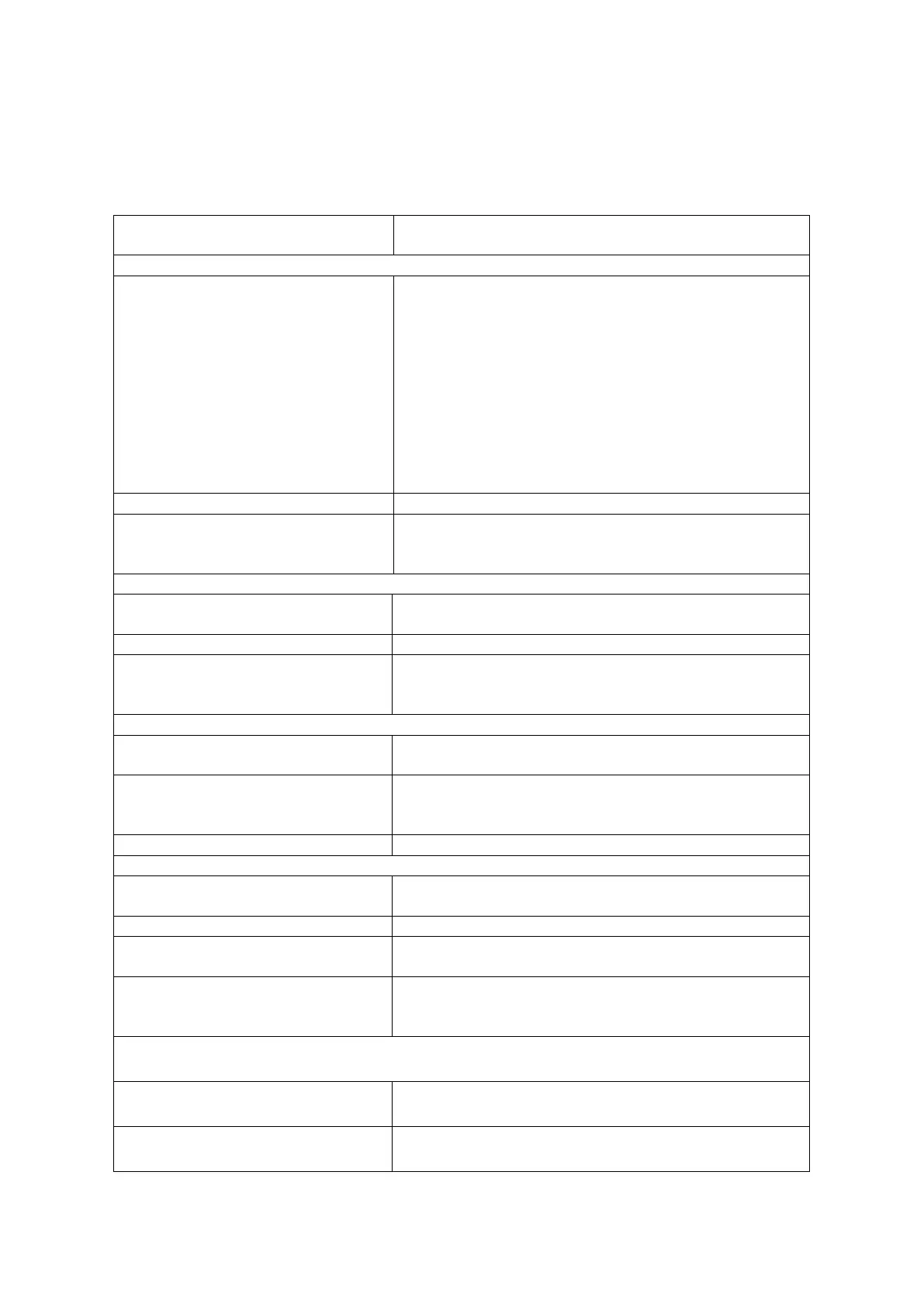

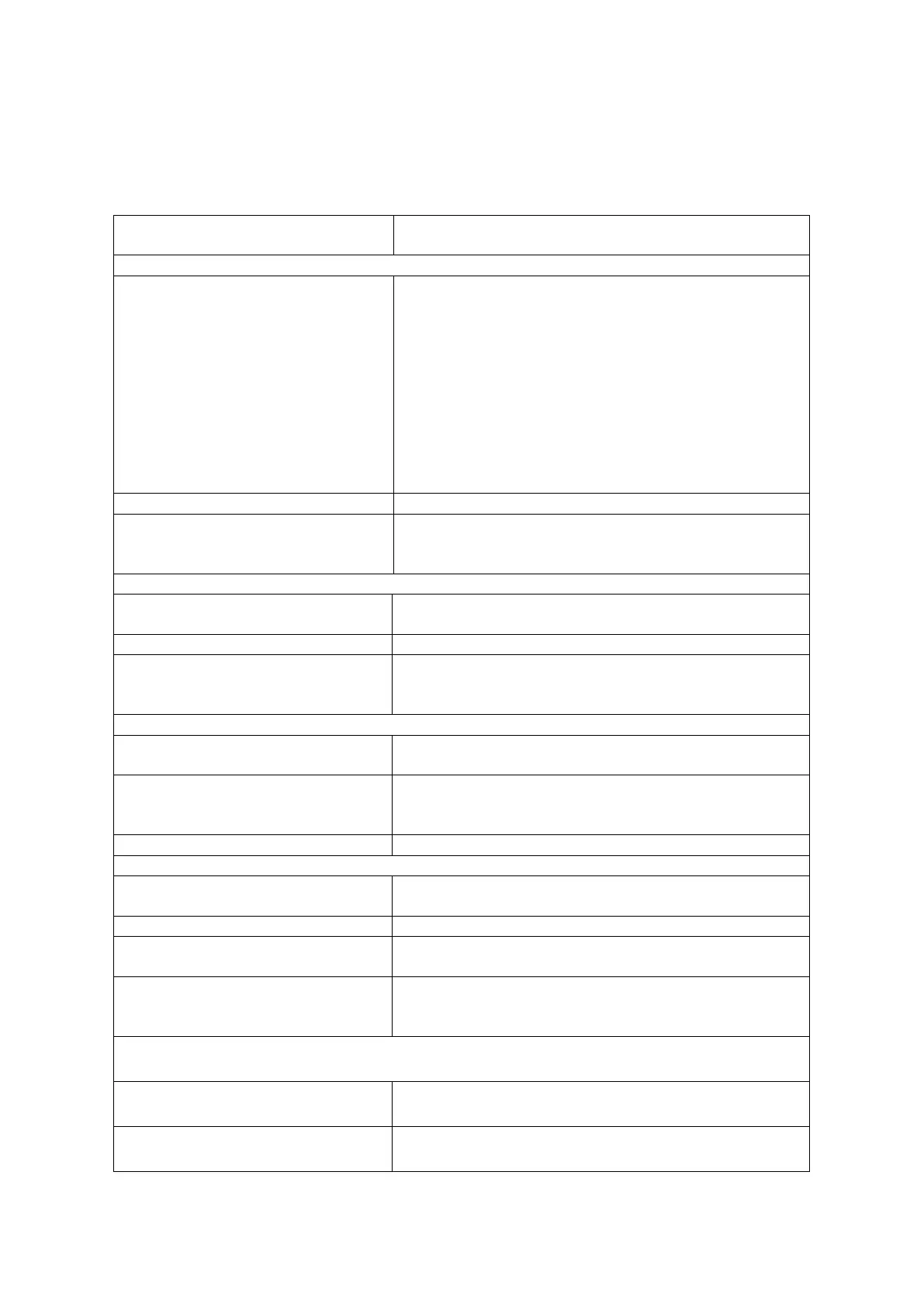

6.10.2 Possible failures of the hydraulic lift linkage without draft control unit

and instructions for troubleshooting

The list of possible failures in the HLL without draft control unit and guidelines for

troubleshooting are given in Table 6.10.2

Table 6.10.2

Failure,

external manifestation

Troubleshooting

RLL fails to rise with agricultural implement attached

There is no pressure in the hy-

draulic system:

- sticking of the bypass valve of

the distributor;

- clogging of the safety valve of

the distributor;

- clogging of the grid of the safe-

ty valve of the distributor;

- insufficient amount of oil in the

Remove valve parts, wash and install in the body.

The valve must move freely

Disassemble the safety valve, flush, reinstall. Ad-

just valve operating pressure

Clean the safety valve grid

Add oil to the tank to the recommended level

Check pump performance, replace if necessary

Weight of the implement ex-

ceeds the al

lowable weight for

the tractor RLL

Use agricultural implements agreed with the man-

ufacturing company

Slow rise of RLL with agricultural implement attached

Air leakage into the hydraulic

system

Locate the leak and fix the defect

Check pump performance, replace if necessary

Weight of the agricultural imple-

ment exceeds the allowable

weight for the tractor lift linkage

Use agricultural implements agreed with the man-

ufacturing company

Foaming of oil in the tank and splashing through the breather

Air leakage into the system

through the suction line

Tighten the fastening and, if necessary, replace

the gaskets of the suction pipe

Air leakage through the self-

tightening seals of the HLL oil

pump

Check the condition of the self-tightening seals

and replace if necessary.

Oil level in the tank is too high

Drain excess oil to reach the recommended level

Increased oil heating during system operation

Insufficient amount of oil in the

tank

Add oil to the tank to reach the recommended lev-

el

Oil lines bent or crushed

Repair dents or replace the oil line

Sticking of the hydraulic distribu-

tor spool

Return the hydraulic control levers to the "neutral"

position after the operation is completed.

Consumption of implement hy-

draulic motors does

not match

the tractor pump flow

Use agricultural implements agreed with the man-

ufacturing company

Agricultural implement fails to hold in transport position

(lowering speed exceeds 20 mm within 10 min)

Oil leakage through piston seals

or cylinder rod seals

Replace cylinder seals or replace the cylinder

Oil leakage through the distribu-

tor spool

Note - The hydraulic circuit diagram for the HLL without draft control unit is present-

ed in Annex B in Figure B2.

Loading...

Loading...