82.3-0000010 OM

129

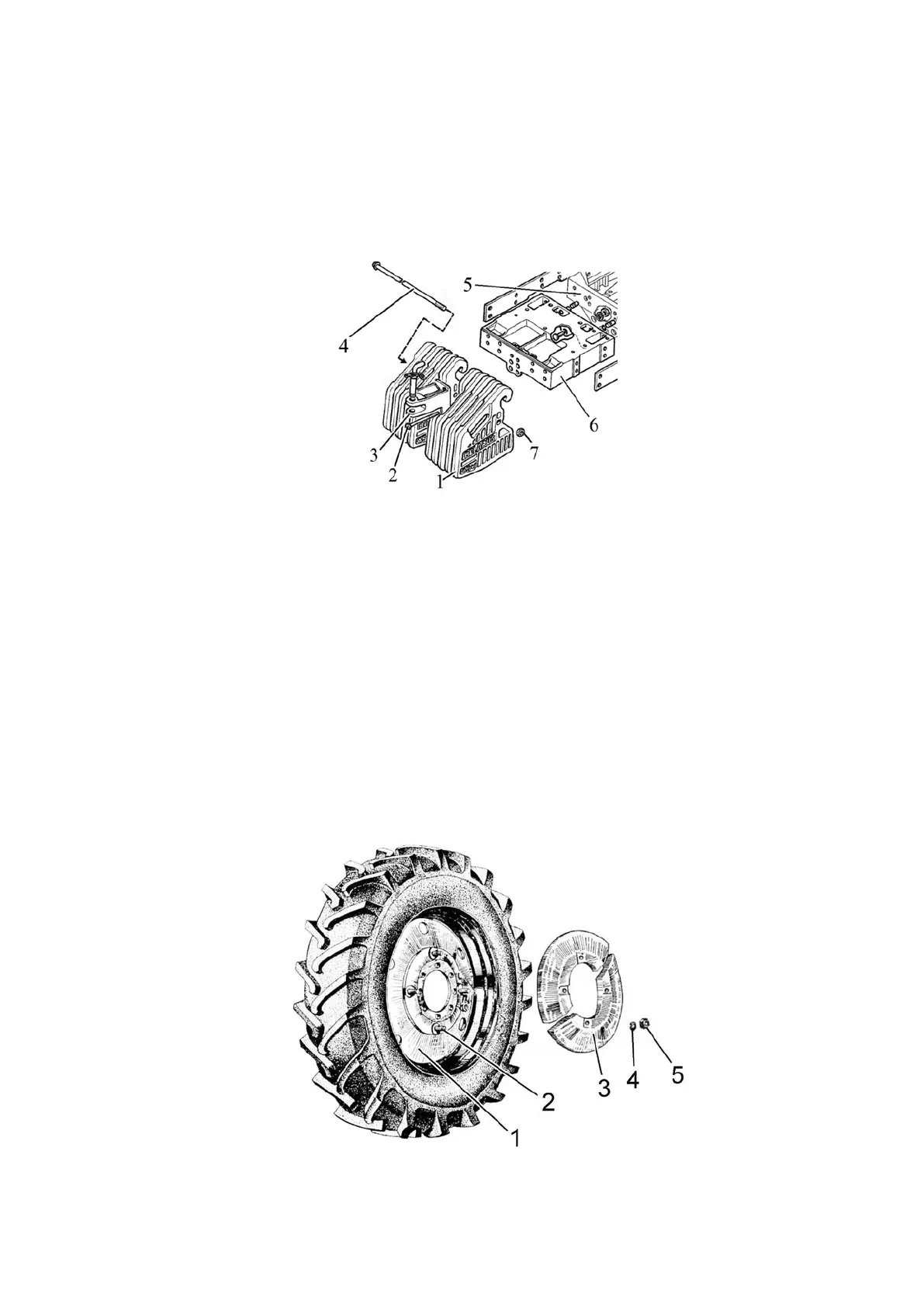

4.6 Ballast weight installation

4.6.1 Front ballast weight installation

When operating with heavy machines and implements coupled, mount supplemen-

tary weights 1 (Figure 4.6.1) to retain normal steerability of the tractor under conditions of

considerable unloading of the front axle. The ballast weights 1 are mounted on a special

bracket 6, which is attached to the front bar 5 of the tractor and is fastened by a string 4

and a nut 7.

1 – supplementary ballast weights; 2 – bolt for fastening supplementary ballast

weights and towing device; 3 – towing device; 4 – string; 5 – front bar; 6 – bracket; 7 – nut.

Figure 4.6.1 – From ballast weight installation

Installation of two types of supplementary ballast weights is possible:

- 450 kg ballast weights (10 pieces 45 kg each);

- 360 kg ballast weights (8 pieces 45 kg each).

The basic configuration includes mounting of 450 kg ballast weights.

Tightening torque of all threaded joints of the front ballast weight shall be from 160

to 180 N⋅m.

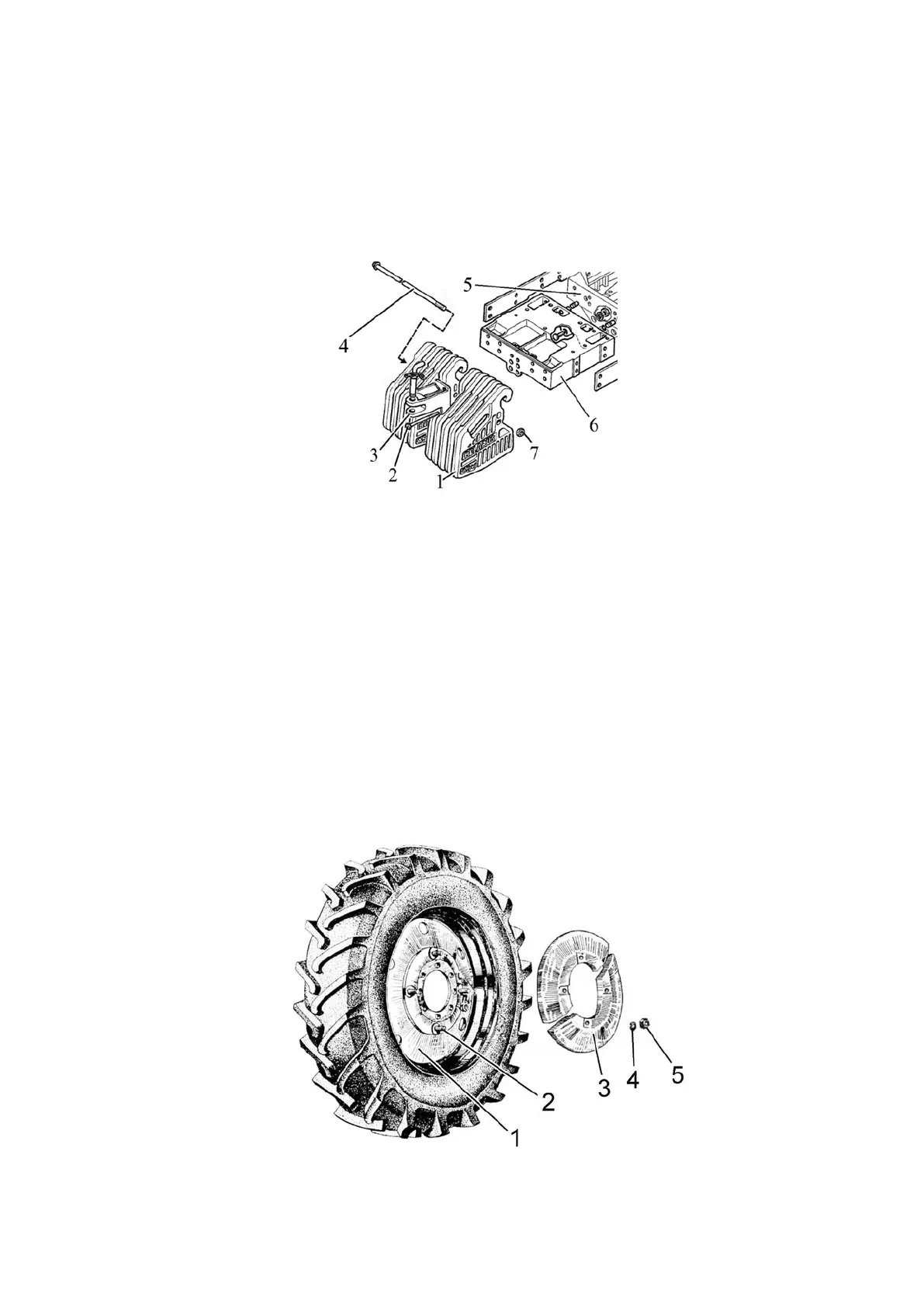

4.6.2 Ballast weight installation on rear wheels

In order to increase tractor adhesive weight, installation of a set of ballast weights

on rear wheel disks is available. The set contains of four ballast weights 3 (figure 4.6.2), 20

kg each. Weight 3 is attached to the wheel disk 1 by means of two bolts 2 and nuts 5.

Tightening torque for nuts 5 shall be from 160 to 220 N⋅m

1 – wheel disk; 2 – bolt; 3 – weight; 4 – spring washer; 5 – nut.

Figure 4.6.2 – Ballast weight installation on rear wheels

Loading...

Loading...