FI002K0018v1100UK – THS/21 Instruction manual for installation, use and maintenance

5

MAINTENANCE

ORIGINAL INSTRUCTIONS 155

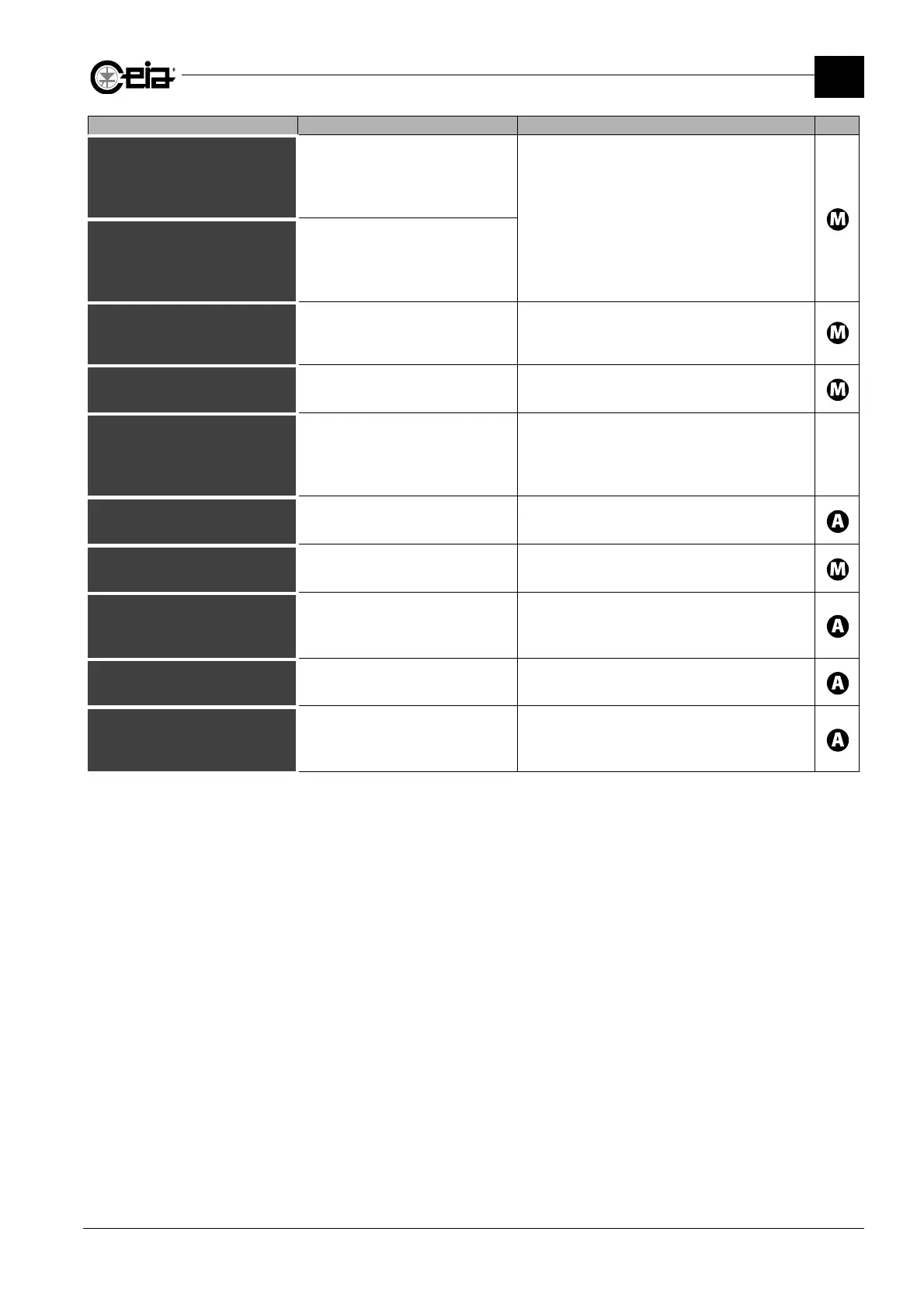

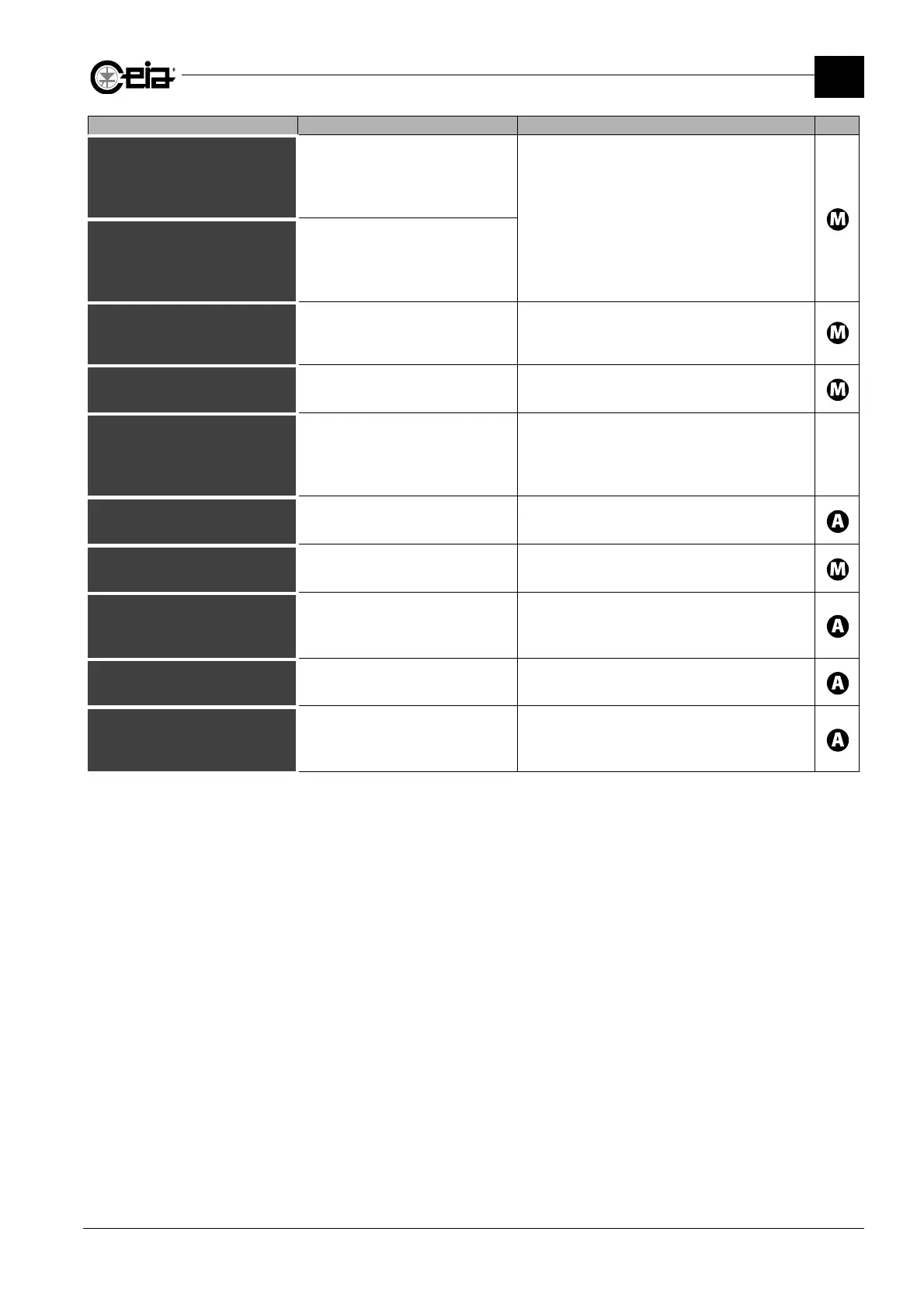

Fault Message Probable cause Action Type

ENCOD.FRQ.TOO LOW

Speed measured by Encoder is

below BL (Control Power Box) or

lower than 0.7 BL (Conveyor Control

System) for 10 seconds

Check that the conveyor belt is moving correctly.

Check that the Encoder parameters are correct,

measuring the speed and verifying in I/O Status

menu that the read speed is correct.

Check the electrical connections of the Encoder

and its mechanical installation.

If the problem persists, contact Assistance

Service.

ENCD.FRQ.TOO HIGH

Speed measured by Encoder is

above BM (Control Power Box) or

higher than 1.3 BM (Conveyor

Control System) for 10 seconds

TEST TIME OUT

Time-out for pre-programmed test

After the Reset, perform the test.

If FT=OFF, the message is shown without Fault

activation.

TEST FAILED

The test has failed

After the reset, check for the causes in section 4.8

and repeat the test. With FF=OFF

LOGIN RESTRICTED

Three consecutive wrong attempts to

access programming (locally or

remotely)

The system administrator must enter programming

and the fault is automatically reset; otherwise

contact CEIA to follow the password recovery

procedure.

-

EVENT BUFFER FULL

Event memory buffer is full.

Contact the Programming and Data management

supervisor to save or print the events.

ALR RATE TOO HIGH

Number of alarms too high (see

ART, ARP and EMEX parameters)

Depending on the programming parameters, reset

the Alarm counter or simply reset the fault.

INVERTER NOT RESP

Communication between Inverter

and ALM card is not working

Check all the inverter connections to/from the ALM

card. If the problem persists, contact Assistance

Service.

SELF-BALANCING

The Metal Detector is in Automatic

Balancing Status.

Wait until the end of the procedure.

WAIT

UPDATING CONFIG

The Metal Detector configuration

update is in progress (at start-up,

changing transmission channel)

Wait until the end of the procedure.

continue >>

Loading...

Loading...