Maintenance 5. Actuator Units

N6 Rev.2 321

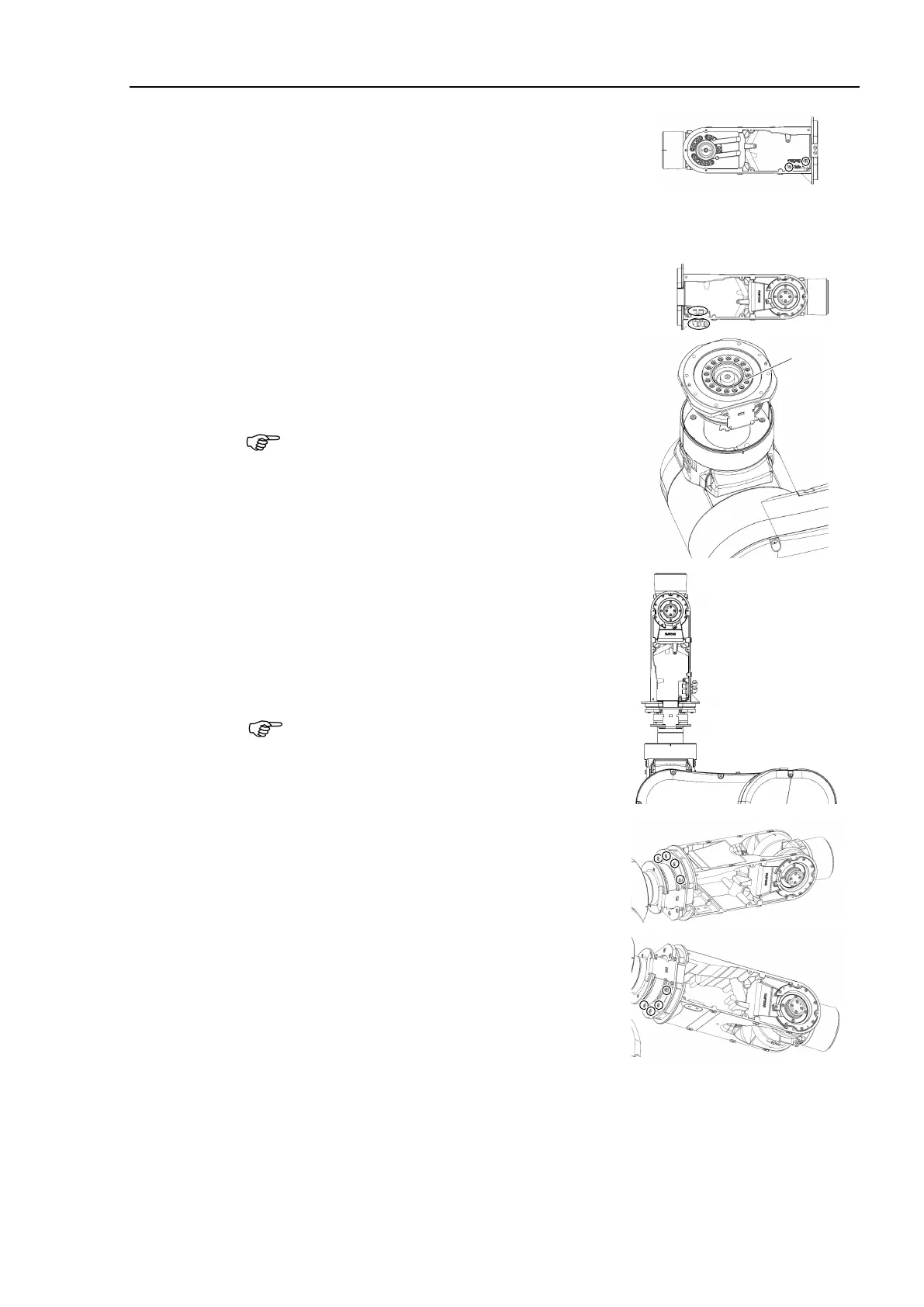

Install the encoder board #4 to the Joint #5 and

#6 units.

Cross recessed binding head machine screws:

2-M3×6

Tightening torque: 0.45 ± 0.05 N·m

Install the air tube fittings to the Joint #5 and #6

units.

-ring to the Joint #4 flange.

O-ring Inner diameter ø 47.5 mm

Wire diameter ø 2.0 mm

thin coat of grease to the O-ring.

Grease: SK-1A

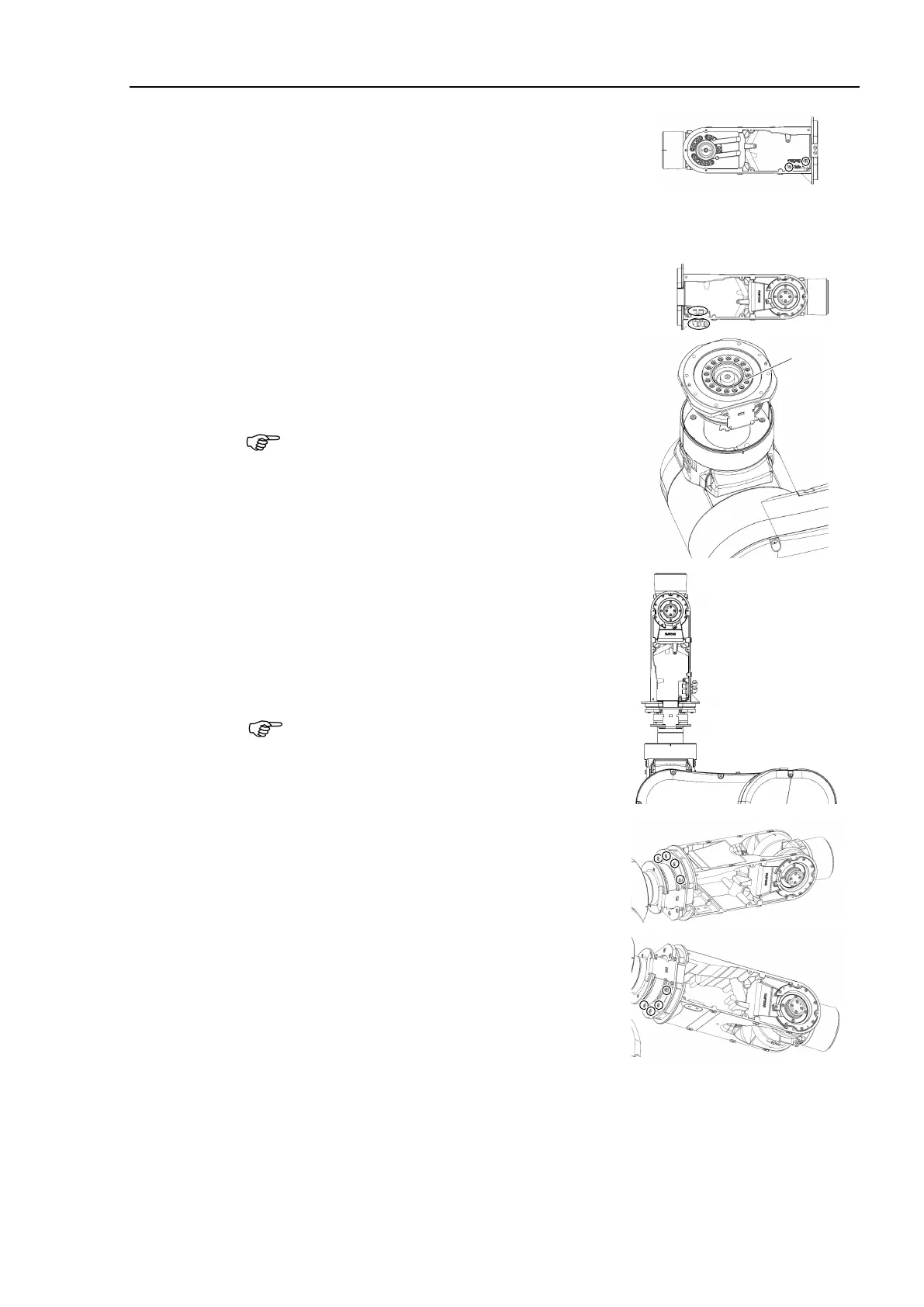

Install the Joint #5 and #6 units on the Joint #4

actuator unit.

Hexagon socket head cap bolts:

8-M4×20 (with plain washer)

Tightening torque: 5.5±0.25 N·m

Be sure to have at least 2 people to perform the

operation since the parts being heavy

.

Confirm that the two pins are installed on the

Joint #4 flange. When installing it, make sure to

align the pins with the Joint #5 and #6 units.

he O-ring properly.

Be careful not to get the cables caught

in the

the actuator unit.

Loading...

Loading...