WinMax Lathe Conversational Part Programming v546CO Conversational Part Programming 2-77

When Linear is selected in the COORDINATES field, these fields appear:

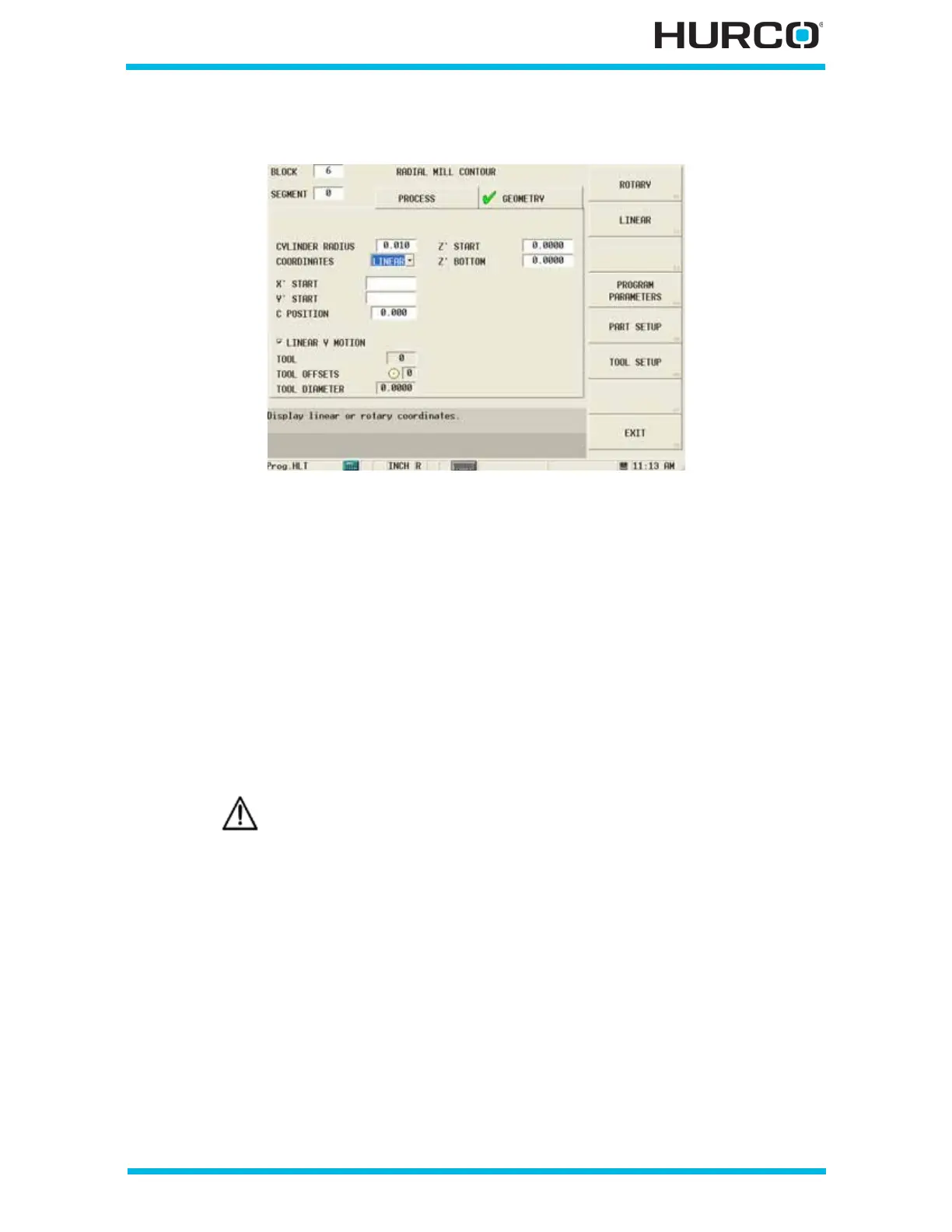

Figure 2–65. Live-Tooling Radial Mill Contour screen Geometry tab: Linear Coordinates

• X’ START—defines the X Startpoint for the first segment of the contour. The

X’ axis will move in the physical Z direction.

• Y’ START—defines the Y Startpoint for the first segment of the contour. The

Y’ axis will be wrapped on the cylinder diameter.

• C POSITION—defines the angle to position the C axis for the first segment

of the contour. This field appears when the Linear Y Motion checkbox is

selected. This field is available with TMX MY and TMX MYS series machines.

• LINEAR Y MOTION—select this checkbox to cause Y-Axis Motion using the X

and X’ axes. When this checkbox is clear, Y-Axis Motion occurs using the X

and C axes. Please refer to Programming Coordinates and Linear Y Motion, on

page 2 - 68 for examples. This field is available with TMX MY and TMX MYS

series machines.

• Z’ START—defines the location where Plunge Feedrate begins. The feedrate

is set in the Plunge Feed field in the Process tab. The Z’ axis will move in the

physical X direction.

• Z’ BOTTOM—defines the bottom of the hole and the location where the

Plunge Feedrate ends. The Z’ axis will move in the physical X direction. These

fields are read-only and are carried over from Tool Setup for the tool specified

in the Process tab.

• TOOL—identifies the tool number that will be used in the part program.

• TOOL OFFSETS—identifies the tool offset and orientation programmed in

Tool Setup that will be used. The tool offset defaults to the same number as

the tool.

• TOOL DIAMETER—contains the tool diameter programmed in Tool Setup for

the current tool. This field is read-only and can only be edited in Tool Setup.

Linear Y-Axis Motion is limited. The amount of Y travel is affected by

the X position and by any X-Axis tool length offset.

Loading...

Loading...