2 - 158 Conversational Part Programming v546CO WinMax Lathe Conversational Part Programming

Geometry Tab

Finishing follows the geometry of the contour defined in the Geometry tab.

Finishing follows the geometry of the contour defined in the Geometry tab. The fields on

the Geometry tab are defined as follows:

• COORDINATES—defines the coordinates as either Rectangular or Polar.

• Rectangular coordinates are used when working from a flat drawing.

• Polar coordinates move around the cylinder as specified.

The remaining fields are based on your selection in the Coordinates field (Polar or

Rectangular).

When Polar is selected in the COORDINATES field, these fields appear:

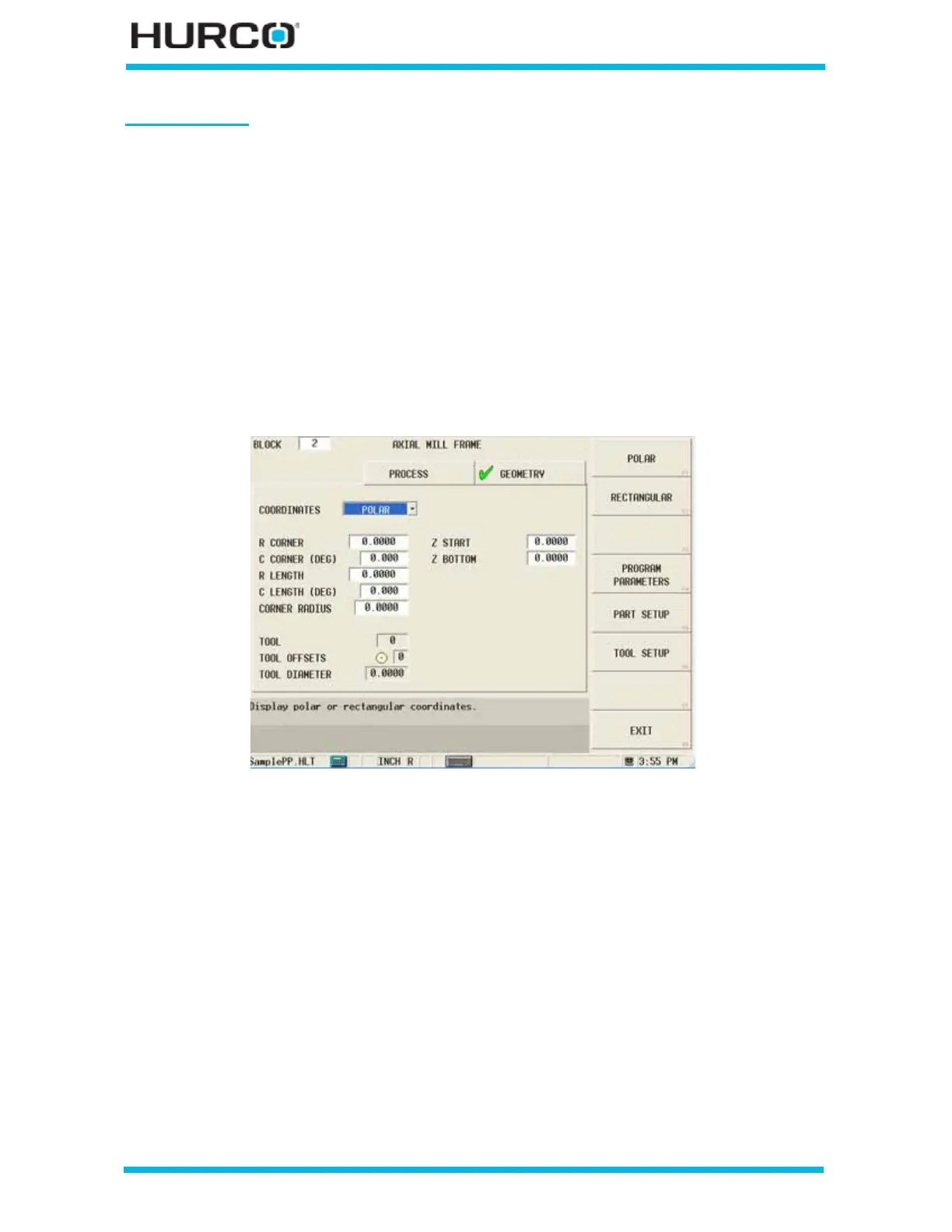

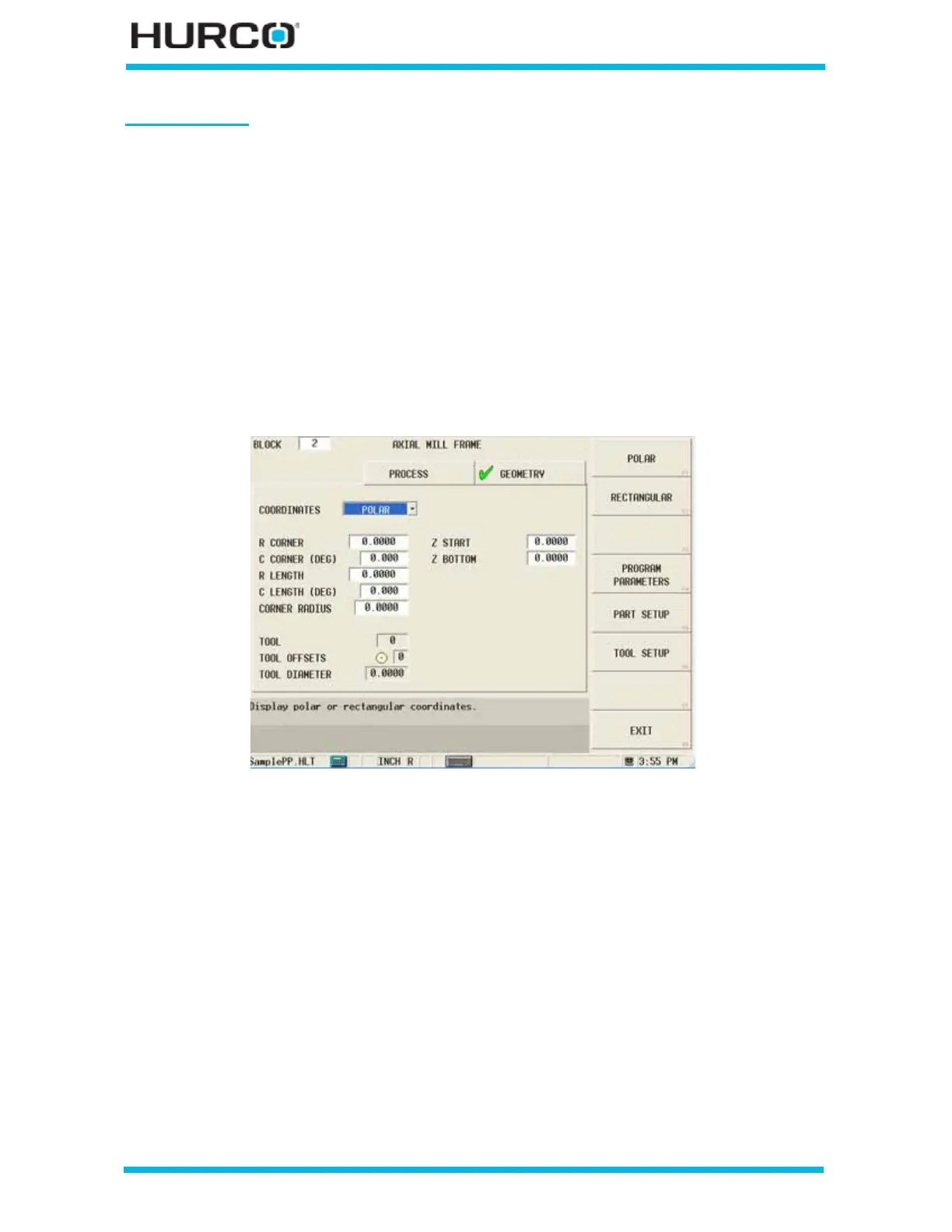

Figure 2–130. Live-Tooling Axial Mill Frame screen Geometry tab: Polar Coordinates

• R CORNER—defines the starting distance from the centerline.

• C CORNER (DEG)—defines the angle of the circle from the start point to the

end point, measured counterclockwise from the home position.

• R LENGTH—defines the starting distance from the centerline.

• C LENGTH (DEG)—defines the length of the frame, in degrees, along the C

axis, measured counterclockwise from the home position.

• CORNER RADIUS—defines the radius of all four corners of the frame, which

becomes the reference corner.

• Z START—defines the location where Plunge Feedrate begins. The feedrate is

set in the Plunge Feed field in the Process tab.

• Z BOTTOM—defines the bottom of the hole and the location where the

Plunge Feed Rate ends.

Loading...

Loading...