2 - 68 Conversational Part Programming v546CO WinMax Lathe Conversational Part Programming

Programming Coordinates and Linear Y Motion

Radial milling is used with TMM, TMX MY, and TMX MYS machines. The programming

coordinates are mapped to behave like milling machines. In order to perform machining

processes for TMM, TMX MY, and TMX MYS machines, WinMax aligns the programming

coordinate system. Machine coordinates do not change.

No Linear Y Motion

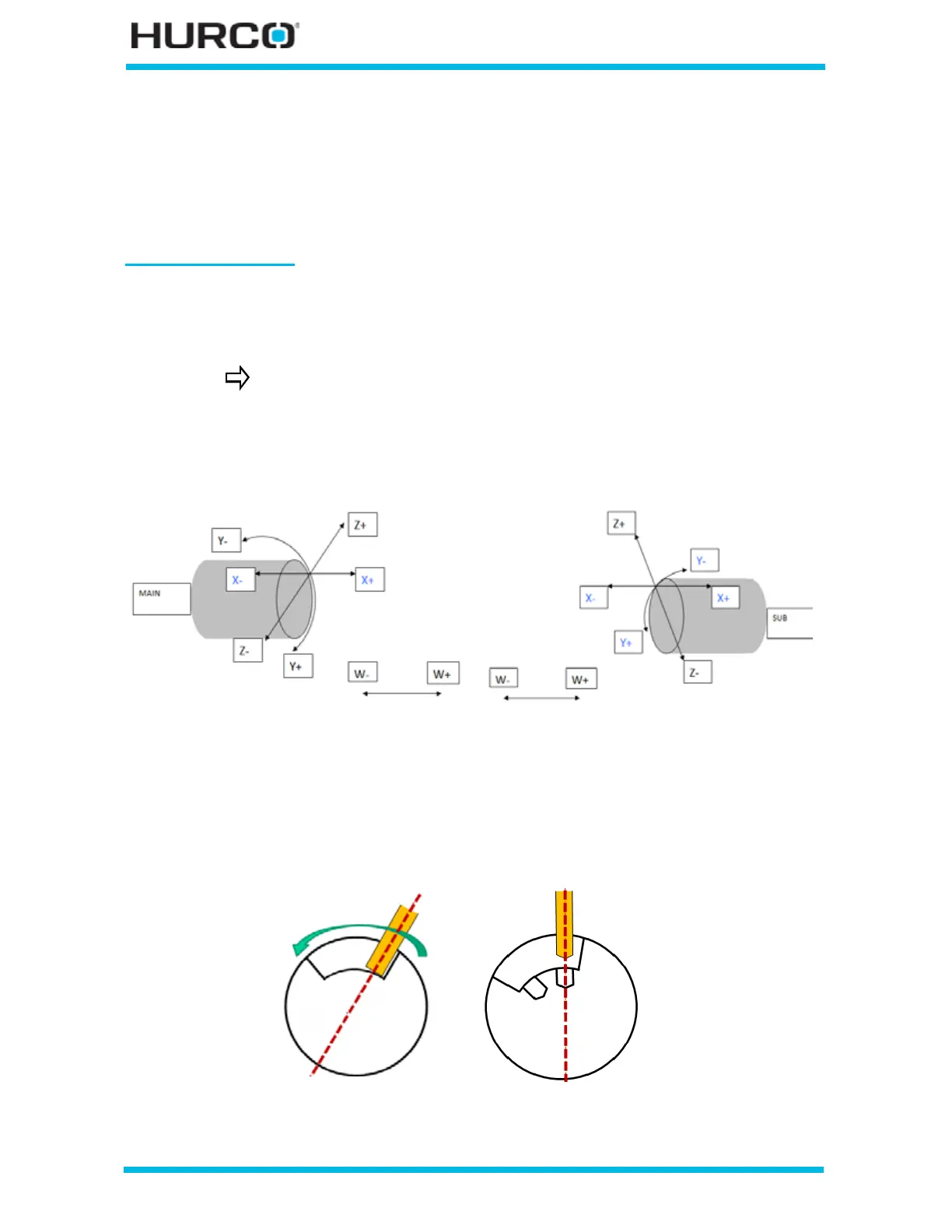

The following figure shows the part coordinate system for TMM, TMX MY, and TMX MYS

machines, for wrapping the Y-Axis coordinate system around the circumference of the

part.

When Linear Y Motion is not selected on the Geometry tab, the Y-axis is wrapped around

the circumference of the part. The X machine coordinate becomes Part Z-axis, and the Z

machine coordinate becomes the Part X-axis. The machine C-Axis rotates for Y motion.

Figure 2–55. Main and Sub-spindle Radial surface of the part without Linear Y

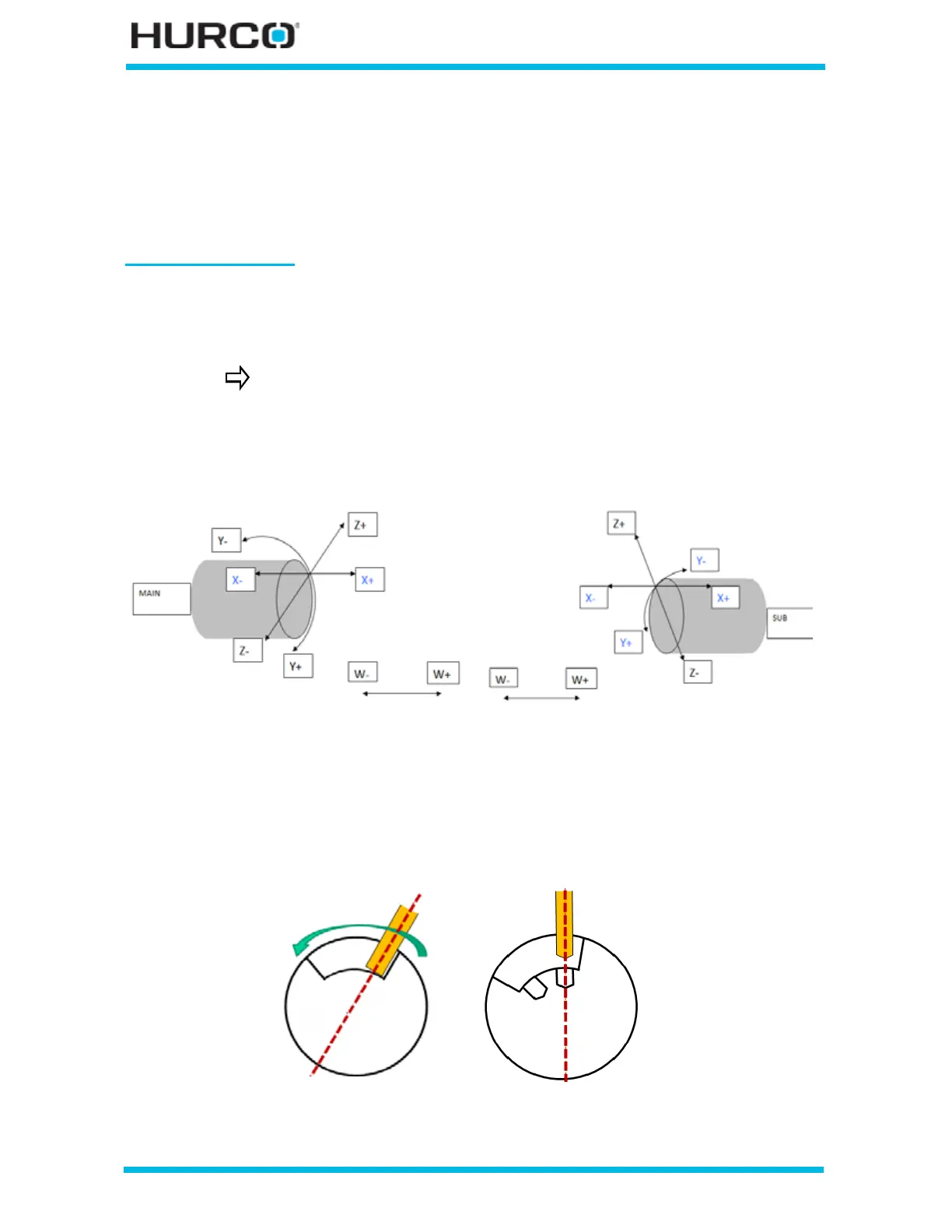

The bottom surface of the feature being machined is concentric to the circumference of

the part:

Figure 2–56. Radial Cutting—C-Axis

TMM machines use this mapping for Radial milling.

Main Spindle Linear Y not selected

Part Coordinate system

Sub-spindle Linear Y not selected

Part Coordinate system

Milling

Drilling

Loading...

Loading...