WinMax Lathe Conversational Part Programming v546CO Conversational Part Programming 2-157

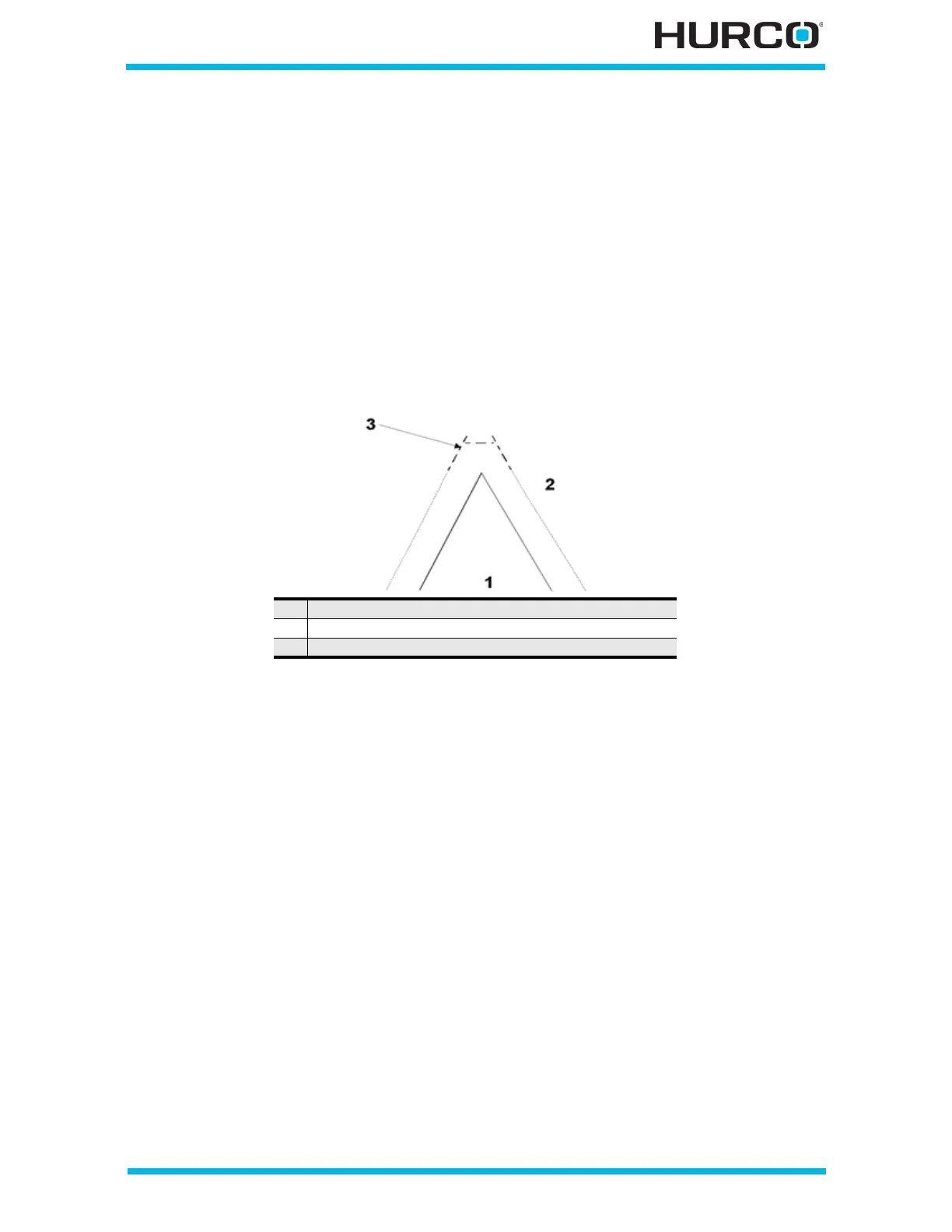

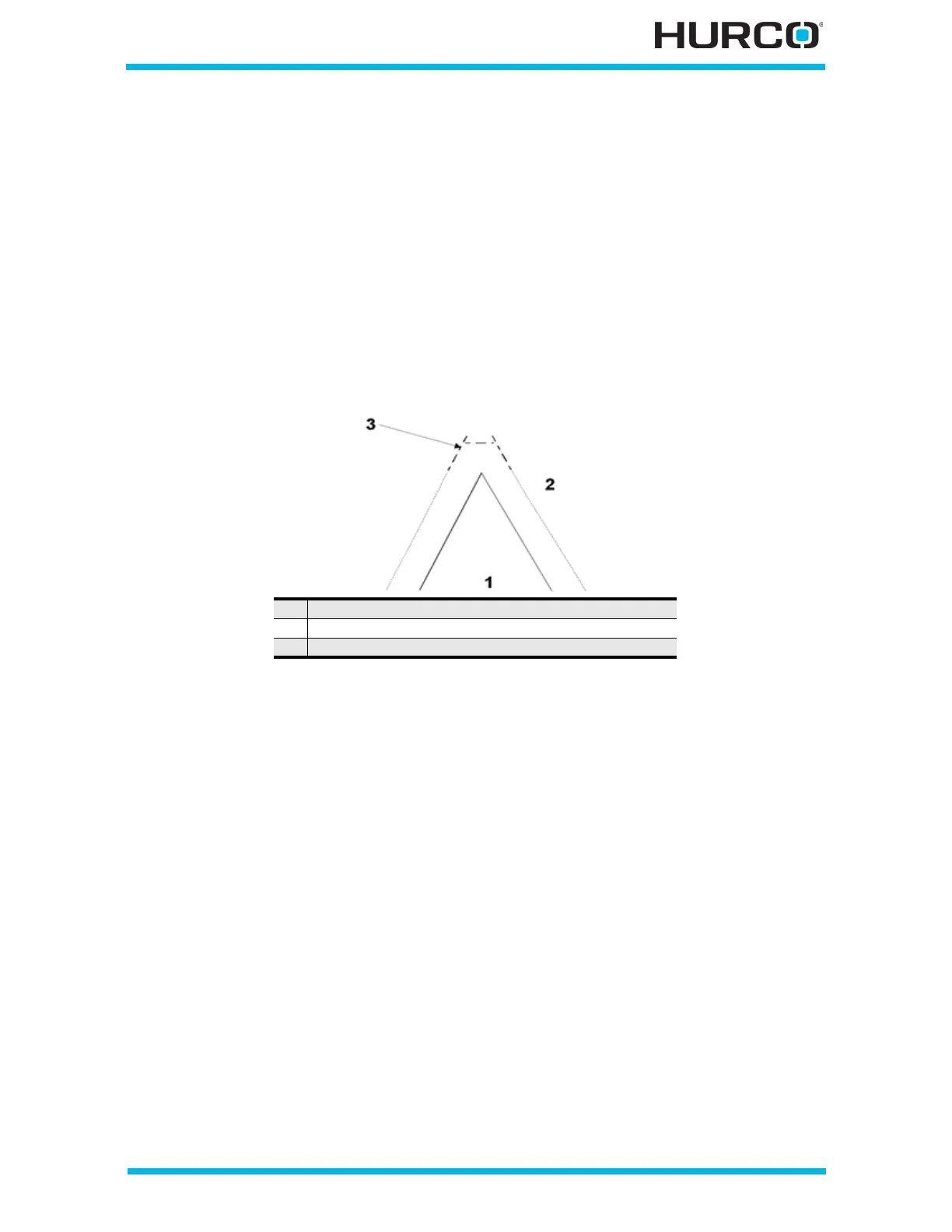

•If the Lines softkey is selected, the cutter compensated lines and arcs are

joined as described below:

• Two line segments are extended until they intersect (provided they

form a 90° or greater angle). If the lines form an angle of less than

90°, a line is inserted to connect them.

• Line and arc segments have the line segment extended, and a tangent

line to the arc segment inserted and extended until the lines intersect

(provided they form a 90° or greater angle). If the segments form an

angle of less than 90°, a line is inserted to connect them.

• Two arc segments have tangent lines (to the arcs) inserted and

extended until the lines intersect (provided the extended tangent lines

form a 90° or greater angle). If the extended tangent lines form an

angle of less than 90°, a line or arc is inserted to connect them.

Figure 2–129. Cutter Compensation Using the Line Parameter

Calculated Plunge Points for Axial Frames

Calculations for determining the plunge points for milling cycles are for TMM, TMX MY, and

TMX MYS Series machines. The following examples are for Axial Frames and Climb Milling.

The Blend-in move is a 90° arc and occurs at the 6:00 position on the frame.

Pocket Type Inward

Xplunge = Xcorner + (XLength/2) - Blend Offset

Yplunge = Ycorner + Blend Offset + Tool radius

Pocket Type Outward

Xplunge = Xcorner + (XLength/2) + Blend Offset

Yplunge = Ycorner - Blend Offset - Tool radius

Roughing

To determine the plunge points for roughing passes, subtract the Wall Allowance from the

Yplunge.

1 Programmed tool path

2 Cutter compensated path

3 Insert Line parameter

Loading...

Loading...