2 - 96 Conversational Part Programming v546CO WinMax Lathe Conversational Part Programming

• TOOL DIAMETER—contains the tool diameter programmed in Tool Setup for

the current tool. This field is read-only and can only be edited in Tool Setup.

• STRATEGY—identifies the tool path with respect to rough or finish.

• ROUGH AND FINISH—perform rough and finish passes.

• ROUGH ONLY—perform a rough pass only.

• FINISH ONLY—perform a finish pass only.

• MILLING TYPE—identifies on which side of the contour the tool should begin

cutting. Refer to Cutter Compensation, on page 2 - 188 for more details.

Select from among these choices:

• ON—used for cutting directly on the programmed path.

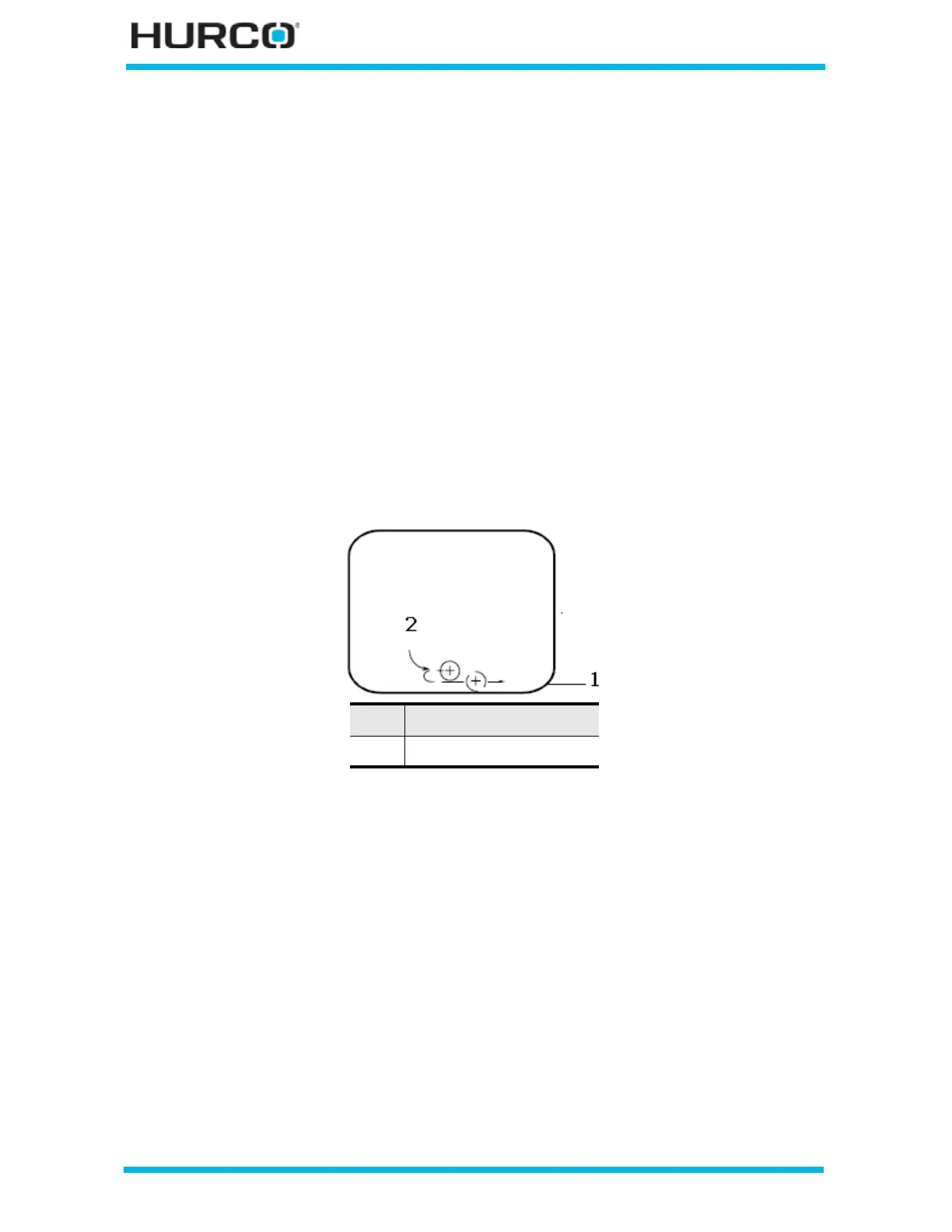

• INSIDE—causes the tool to enter the part inside the contour of the frame

and blend into it using a 180° arc. Cutter compensation is automatically

employed and the outside edge of the tool follows the contour (the

direction the tool travels depends upon milling direction). The point where

the tool enters the part is determined by the blend offset and the point

where the tool is withdrawn is determined by the blend overlap and blend

offset. The following is an example of an Inside frame:

Figure 2–81. Inside Mill Frame Operation

• OUTSIDE—similar to the Inside function, except the tool enters the part

outside the frame and follows the outside of the contour. The tool is

withdrawn adjacent to the frame.

• IN/TAN (INSIDE TANGENT)—causes the tool to enter the part

adjacent to the inside frame contour. Cutter compensation is

automatically used and the edge of the tool follows the inside of the

contour. The direction the tool travels depends upon the milling direction.

The tool is withdrawn from the part adjacent to the frame.

• OUT/TAN (OUTSIDE TANGENT)—similar to the Inside Tangent function

except that the tool enters the part adjacent to the outside frame contour.

The tool’s edge then follows the outside of the contour. The tool is

withdrawn from the part adjacent to the frame.

• POCK BOUNDARY (Pocket Boundary)—used for cutting the outside

perimeter of a pocket operation.

1 Reference Corner

2 Cutter Entry Position

Loading...

Loading...