The speed setpoint of the drive is internally driven down an adjustable ramp (CS.DEC) to 0

V. With default values the output for the brake is switched on when the speed has reached

120 rpm (CS.VTHRESH) for at least 6 ms (CS.TO). The rise (t

brH

) and fall (t

brL

) times of the

holding brake that is built into the motor are different for the various types of motor (see motor

manual).

8.11 Feedback Connection

Every closed servo system normally requires at least one feedback device for sending actual

values from the motor to the drive. Depending on the type of feedback device used, infor-

mation will be fed back to the drive using digital or analog means.

AKD supports the most common types of feedback device. Two feedback devices can be

used at the same time, and all feedbacks are connected to X10. Feedback functions are

assigned with parameters in WorkBench, the setup software. Scaling and other settings are

also performed in WorkBench. For a detailed description of the parameters, please refer to

the WorkBench online help.

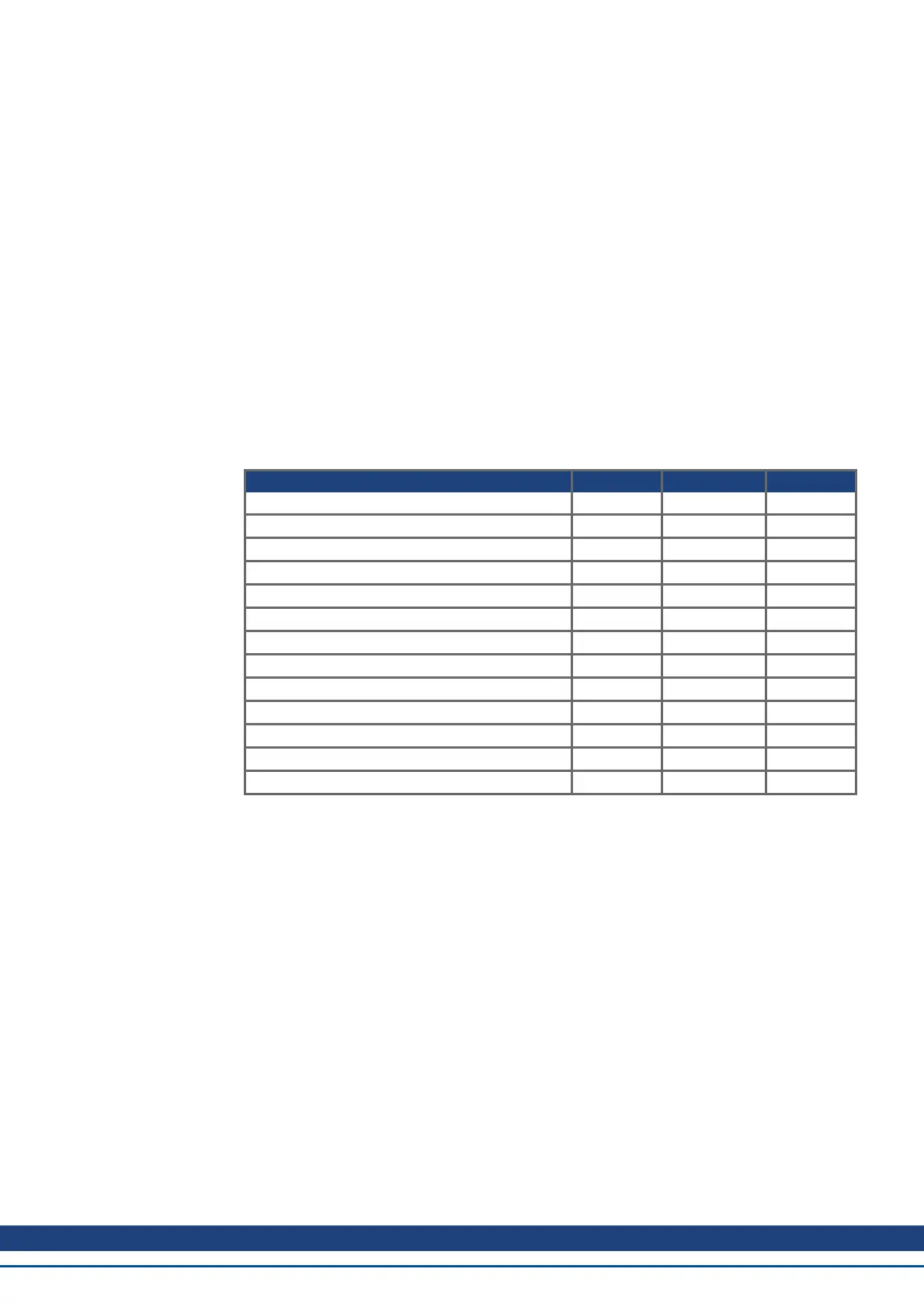

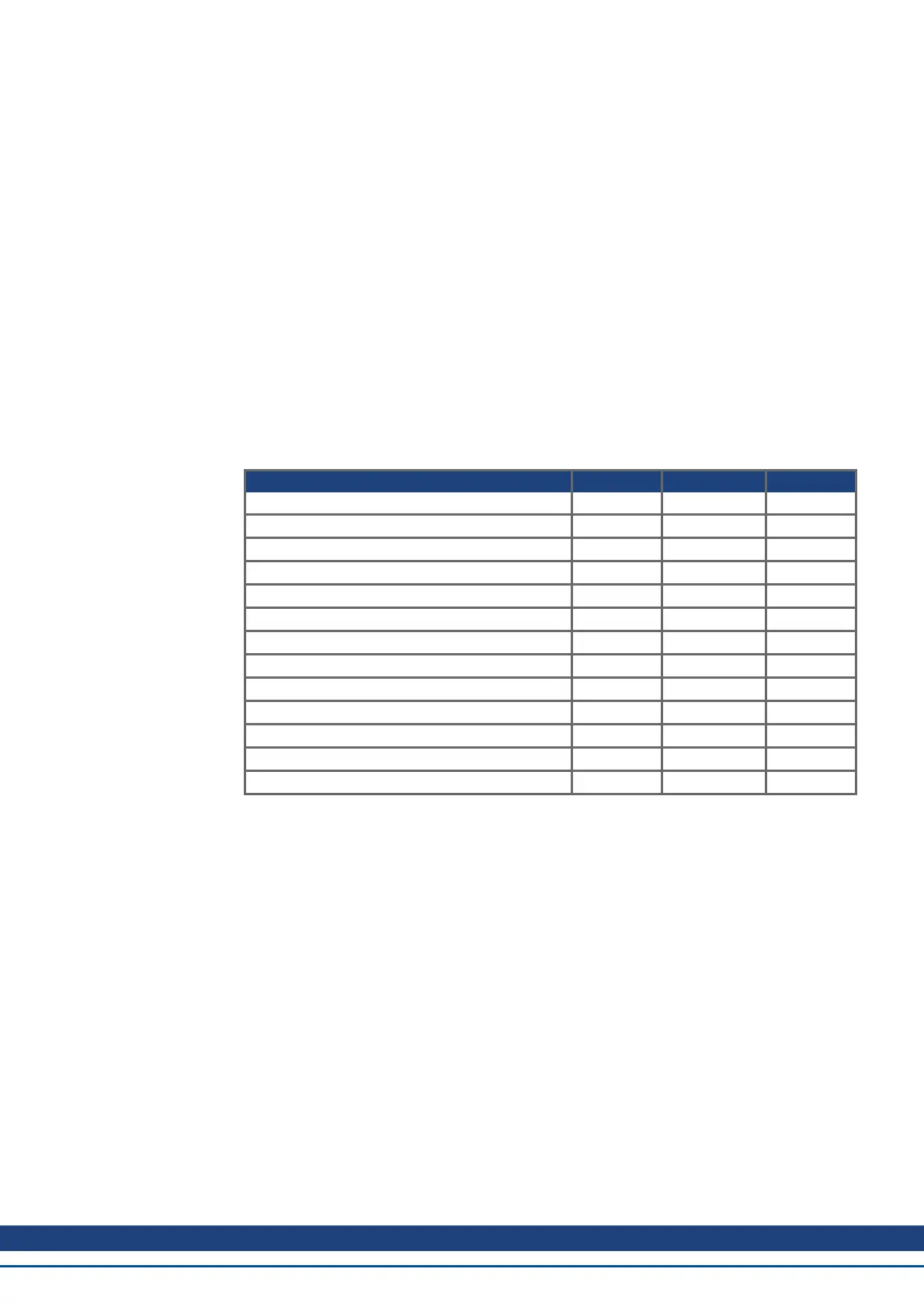

The table below provides an overview of the supported feedback types, their corresponding

parameters, and a reference to the relevant connection diagram in each case.

Feedback Types Wiring Connector FBTYPE

Resolver ➜ p. 105 X10 40

SFD ➜ p. 106 X10 41

Hiperface DSL ➜ p. 107 X10 46

SinCos Encoder BiSS A (analog) ➜ p. 108 X10 32

SinCos Encoder BiSS C (digital) ➜ p. 109 X10 34

SinCos Encoder ENDAT 2.1 ➜ p. 110 X10 30

SinCos Encoder ENDAT 2.2 ➜ p. 111 X10 31

Tamagawa Smart Abs ➜ p. 115 X10 42

SinCos Encoder Hiperface ➜ p. 112 X10 33

Sine Encoder + Hall ➜ p. 113 X10 20

Sine Encoder (Wake&Shake) ➜ p. 113 X10 21

Incremental Encoder + Hall ➜ p. 114 X10 10

Incremental Encoder (Wake&Shake) ➜ p. 114 X10 11

AKD Installation | 8 Electrical Installation

Kollmorgen™ | May 2013 103

Loading...

Loading...