AKD Installation | 8 Electrical Installation

8.19.2 Baudrate for CAN-Bus

The user can decide to use a fixed baud rate or an auto baud detection algorithm for the

startup behaviour of the drive. The transmission rate can be set via the parameter

FBUS.PARAM01. The parameter FBUS.PARAM01 can either be set via WorkBench or via

a special mechanism with the rotary switches in the AKD front.

Baudrate

[kBit/s] FBUS.PARAM01

Upper rotary

switch S1

Lower rotary

switch S2

auto 0 9 0

125 125 9 1

250 250 9 2

500 500 9 3

1000 1000 9 4

In case of a fix baud rate, the drive sends the boot up message with the baud rate saved in

the drive's non volatile memory after a power cycle. In case of auto baud detection, the drive

listens for a valid CAN frame on the bus. When a valid frame is received, the drive sends the

boot up message with the measured bit time. Afterwards the baud rate can either be stored to

non volatile memory via object 1010 sub 1, or the auto baud mechanism is used always.

For reliable auto baud detection, it is recommended to use suitable cabling of the CAN-Bus

(two terminators, GND connection etc.). Spikes or other noise effects on the CAN-Bus can

disturb the measurement. The drive needs to be disabled, if auto baud is in use.

For setting the baudrate with rotary switches, follow the procedure below (drive state dis-

abled):

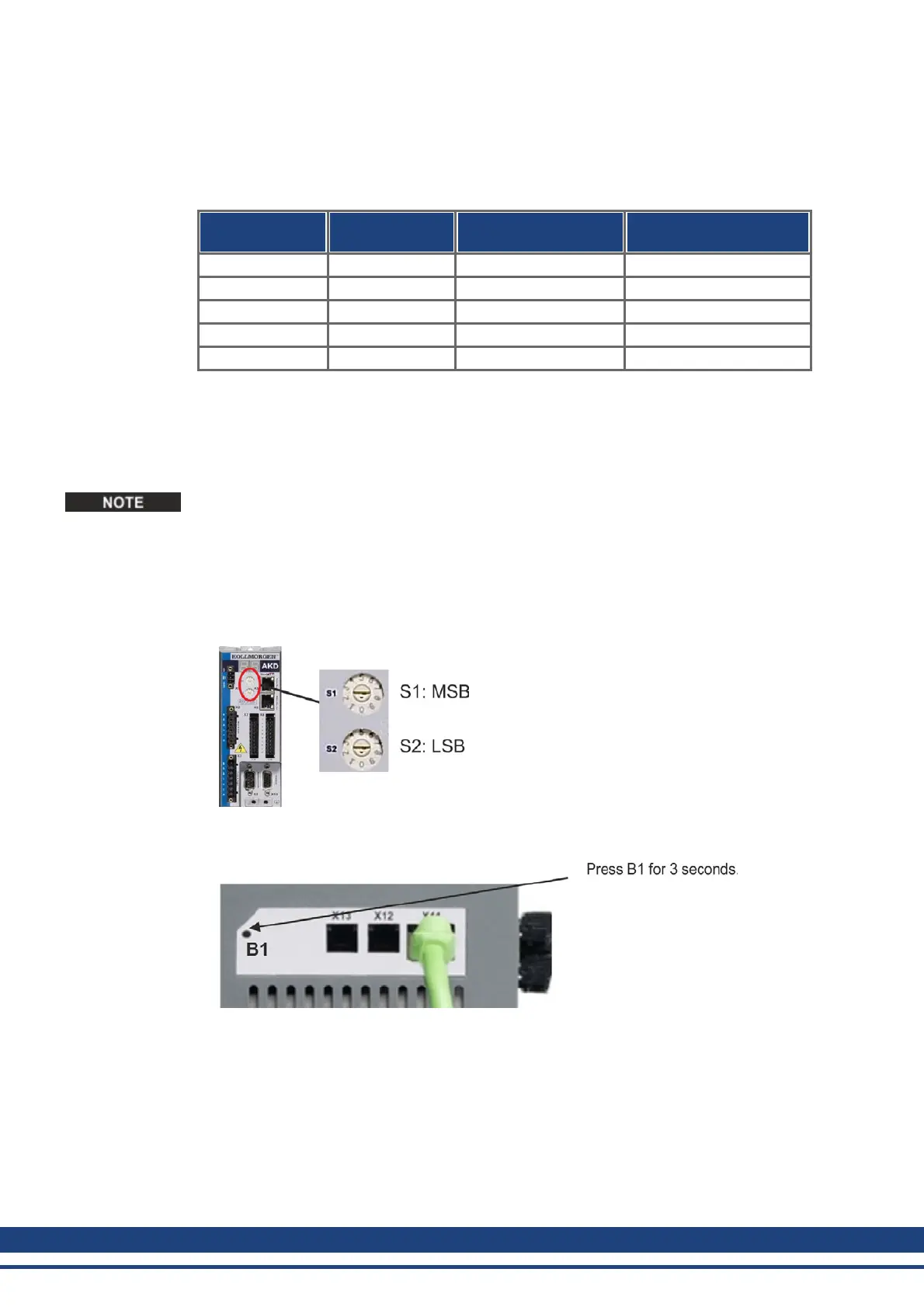

1. Disable the drive. Set the rotary switches to one of the addresses 90 to 94 (see above

table).

Set S1 to 9 and S2 to either 0 or 4

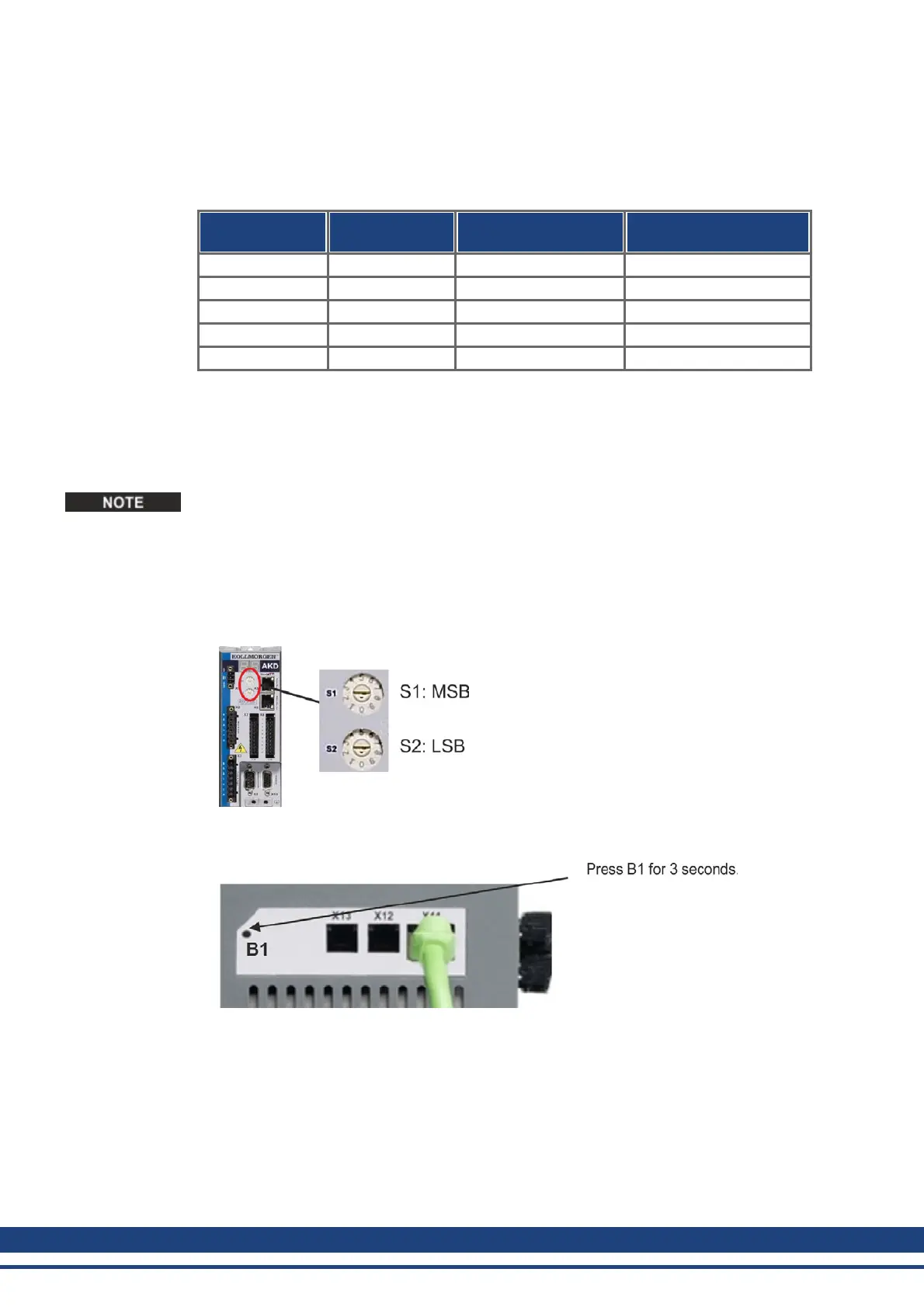

2. Push the button B1 on the AKDfor at least 3 seconds until the rotary switch setting is dis-

played on the AKD-display.

3. When the display blinks with the set rotary switch setting stop pushing B1 and wait until

the blinking stops. During that time the parameter FBUS.PARAM01 is set to the new

value and all parameters are stored to the non volatile memory. The new setting will be

taken with the next power-up of the drive.

If an error occurred, the following error messages will flash 5 times:

l E1 - Drive is enabled

l E2 - Non-volatile storage of the new setting failed

l E3 - Invalid rotary switch selection

154 Kollmorgen™ | May 2013

Loading...

Loading...