Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23 1135

15 Parameter reference

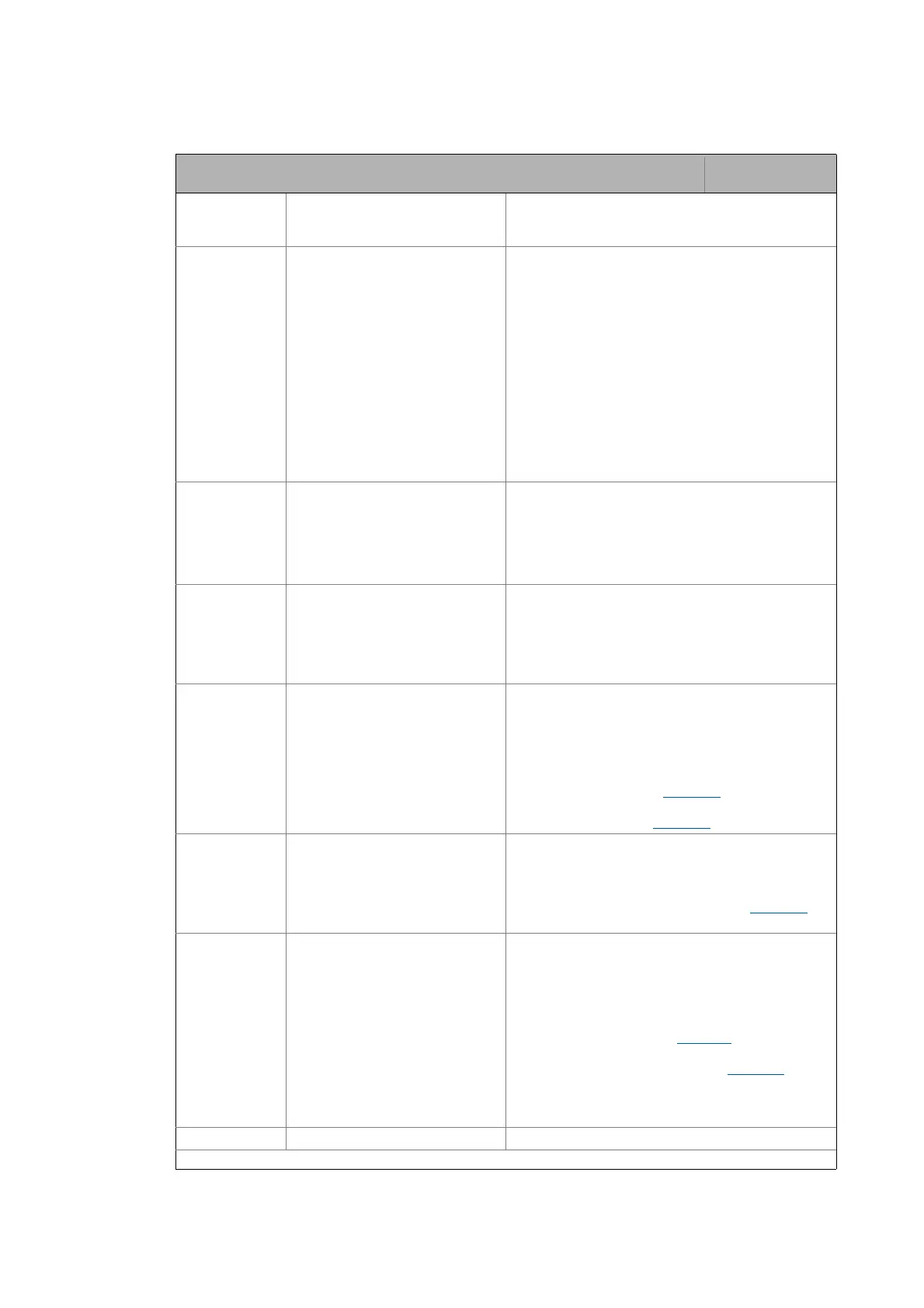

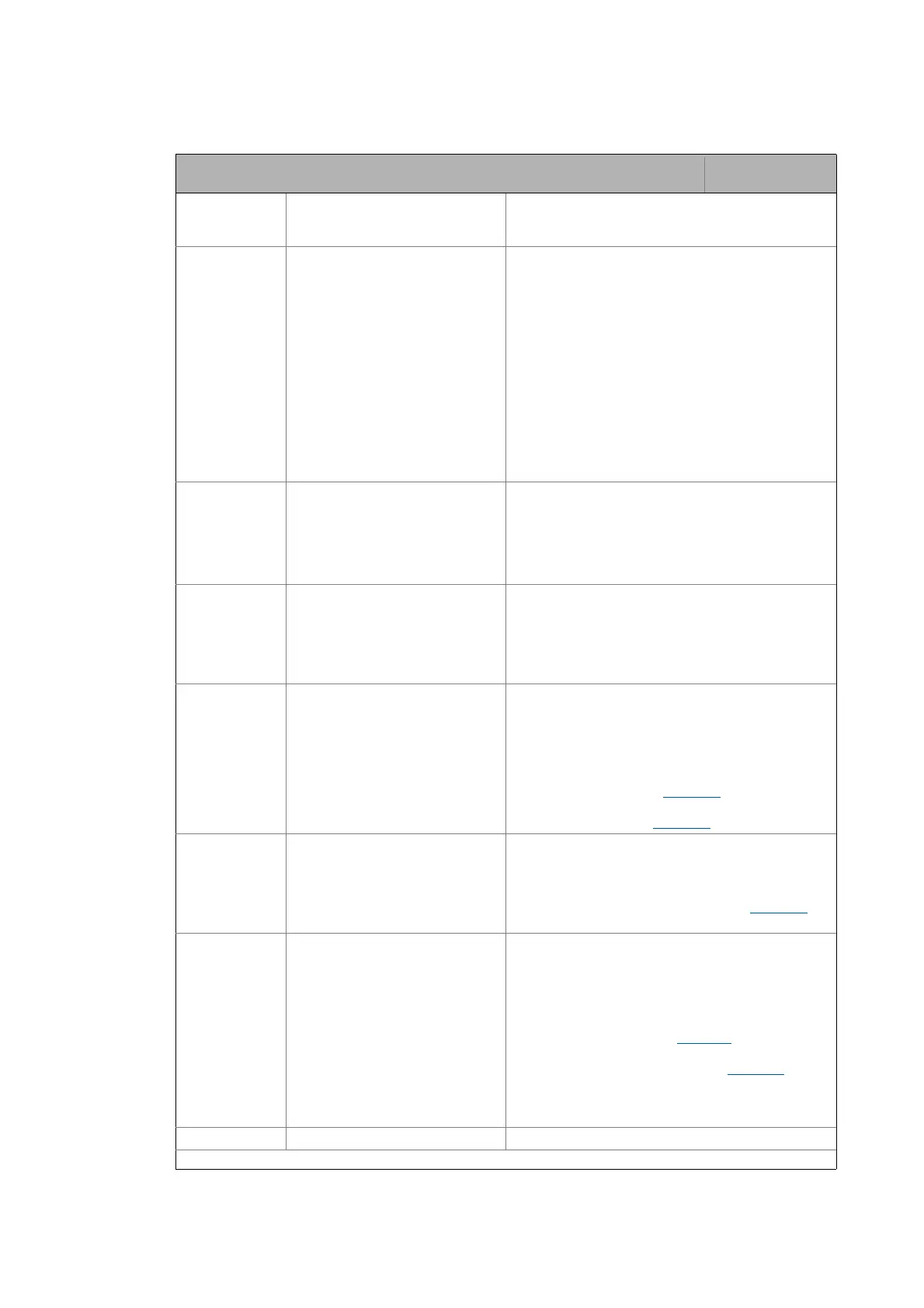

15.2 Parameter list

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Bit 0 bMBrakeReleaseOut invert. Activation of inverted control

•1 ≡ Inverted logic of the control signal for the holding

brake control switching element.

Bit 1 Horizontal brake protection Brake response in case of pulse inhibit

•1 ≡ In the case of a pulse inhibit, the actual speed

value is monitored which must reach the "Close"

threshold value to cause the holding brake to be

applied.

Note:

• This function is only active if bit 3 (horizontal/

winding technology) is set as well. The function is

used in order that, when the controller is inhibited,

the holding brake of a drive with horizontal traverse

path does not wear out during rotation.

• With vertical motion (bit 3 = 0), this function is not

active. Especially with hoists and activated pulse

inhibit of the inverter, an immediate application of

the brake is essential for safety-related reasons!

Bit 2 with hoist inv. feedfwd. control Direction of feedforward control with vertical/hoist

technology:

•0 ≡ Positive direction

•1 ≡ Negative direction

Note:

Reversal (Ccw) is then considered.

Bit 3 Horizontal application Direction of movement of the axis

•0 ≡ The axis performs vertical movements.

Gravitational acceleration causes movements.

•1 ≡ The direction of the axis is horizontal or rotary. The

gravitational acceleration does not cause any

movement.

Bit 4 Feedforward control C2581 From version 06.00.00

Selection of the feedforward control value

•0 ≡ Automatic selection.

• The torque saved at the last stop is used.

•1 ≡ Manual selection.

• bMBrakeStartValue2 = FALSE: The feedforward

control value 1 set in C02581/4

is used.

• bMBrakeStartValue2 = TRUE: The feedforward

control value set in C02581/5

is used.

Bit 5 Feedback monitoring From version 06.00.00

Activation of status monitoring

•1 ≡ The bMBrakeApplied input for status detection of

the brake (via a switching contact at the brake) is

monitored after the waiting time set in C02589/3

has

expired.

Bit 6 SyncRampe L_NSet_1 From version 11.00.00

Selection of the ramp time for the synchronisation

process to setpoint speed after the brake opening time

has elapsed

Revised behaviour from version 11.00.00:

•1 ≡ The ramp time of the effective acceleration of the

ramp function generator (L_NSet_1

) is used (Lenze

setting).

•0 ≡ As before, the ramp time set in C02610/1

is used.

Note:

The changeover can be dynamically both via the ramp

parameter and via bit 6.

Bit 7 Reserved

Read access Write access CINH PLC STOP No transfer COM MOT

Parameter | Name:

C02582 | Holding brake: Setting

Data type: UNSIGNED_8

Index: 21993

d

= 55E9

h

Loading...

Loading...