Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23 531

8 Basic drive functions (MCK)

8.4 Basic settings

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

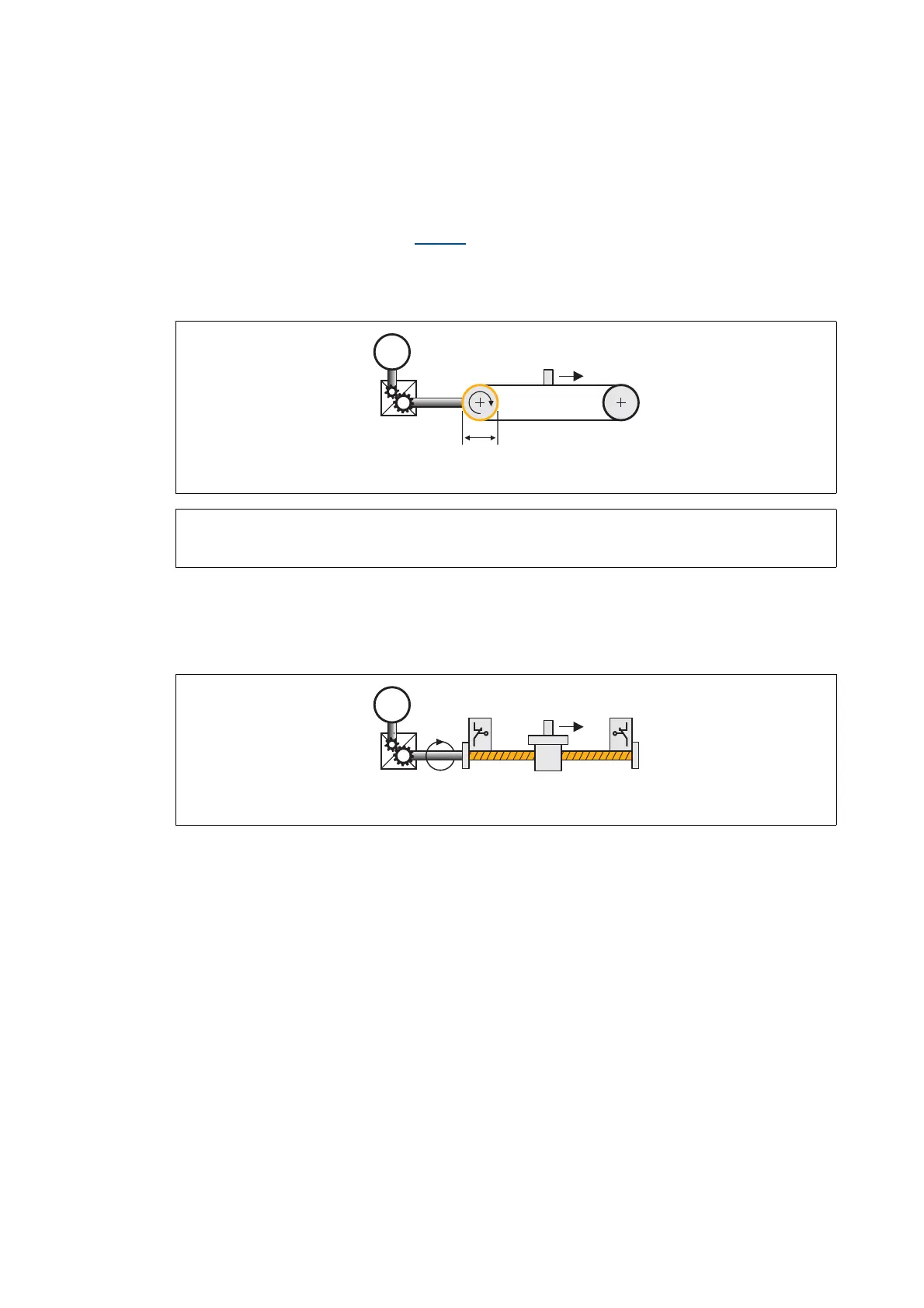

8.4.1.2 Feed constant

The feed constant corresponds to the movement of the machine during one revolution of the

gearbox output shaft.

• The entry in the Feed constant (C01204

) field is made in the user unit [units] in respect of the

revolution.

• In the case of a conveyor drive, the feed constant is obtained from the drive roll's circumference,

which, in the following example, is calculated on the basis of the indicated diameter:

[8-11] Schematic diagram: Feed constant for a conveyor driver

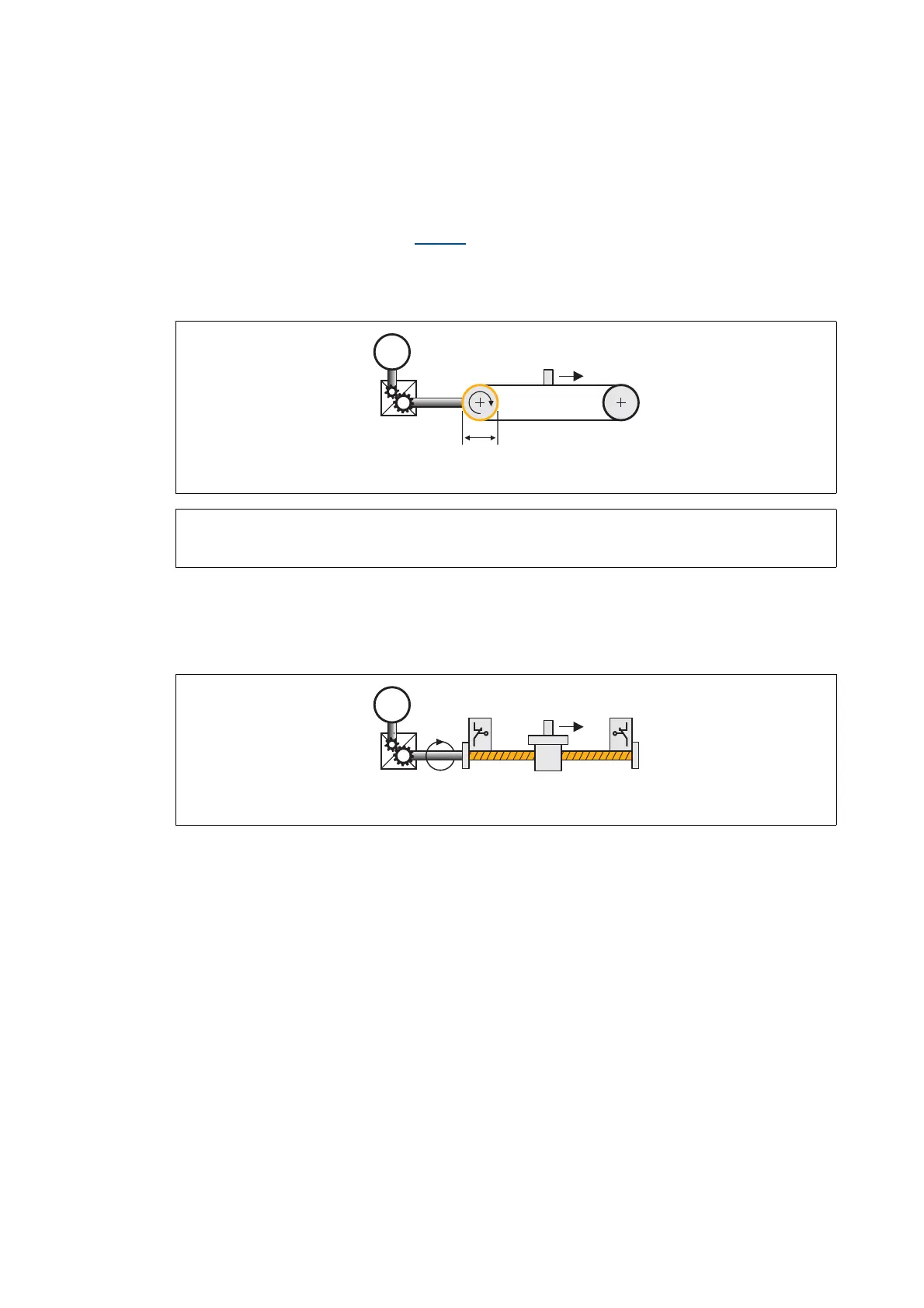

• In the case of a spindle drive (linear axis), the feed constant is derived from the leadscrew pitch.

The feed constant indicates the distance the slide travels during one revolution of the spindle

(in the following example: 5.023 mm).

[8-12] Schematic diagram: Feed constant for a spindle drive

• In the case of a rotary table and its specification as an angle, the feed constant

is = 360°/revolution.

d = diameter

Feed constant π d

[unit]

Revolution

----------------------------

π 200

mm

Revolution

----------------------------

628.3185

mm

Revolution

----------------------------

=⋅=⋅=

h = leadscrew pitch (can be obtained from the technical data of the linear axis)

Loading...

Loading...