5 Motor control (MCTRL)

5.8 Sensorless control for synchronous motors (SLPSM)

214

Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.8.3 Basic settings

The following "Initial commissioning steps" must be performed to commission the sensorless

control for synchronous motors:

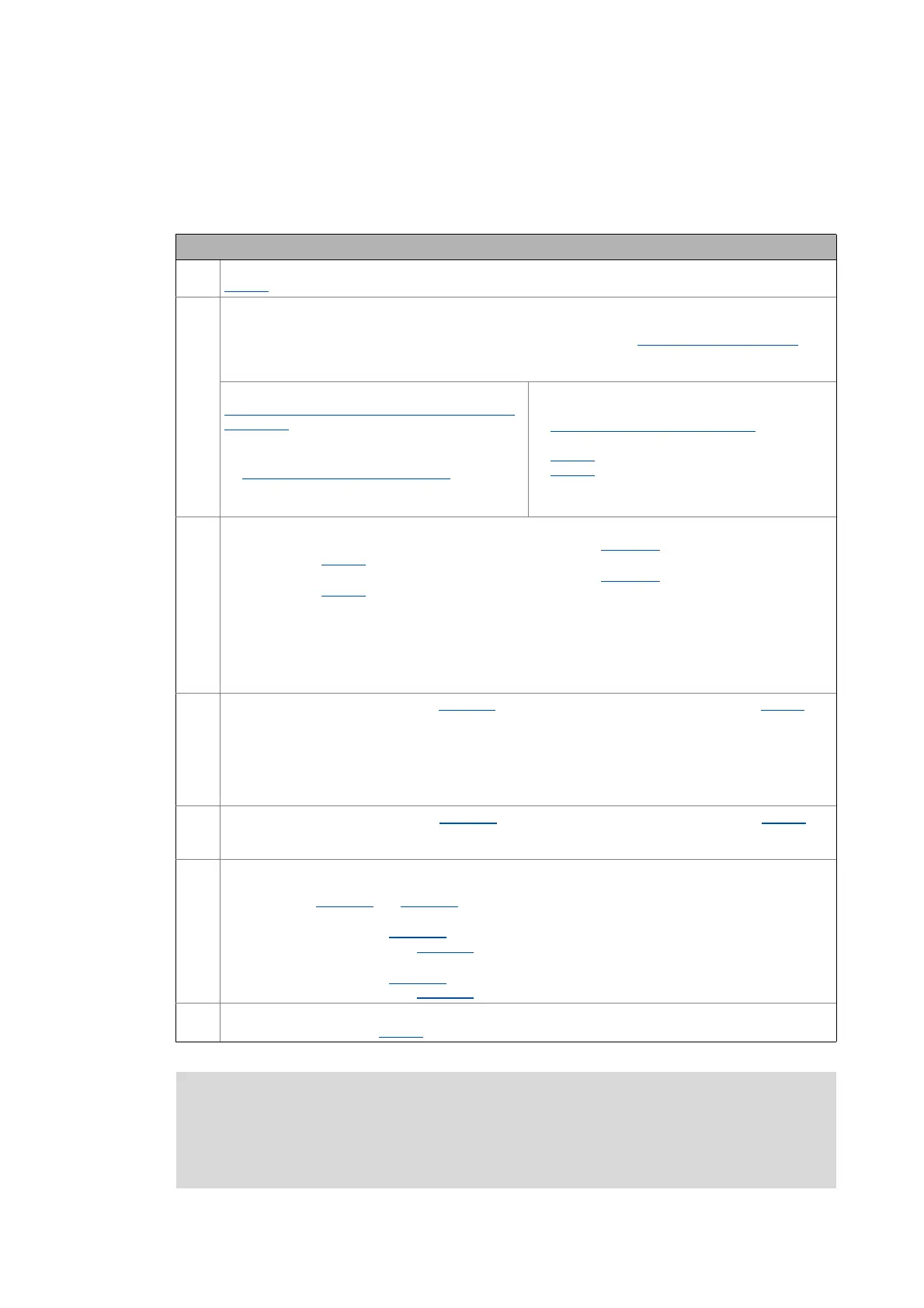

Initial commissioning steps

1 Select motor control:

C00006

= "3: SLPSM: Sensorless PSM"

2. Set the motor selection/motor data

• When selecting and parameterising the motor, the motor nameplate data and the equivalent circuit

diagram data are relevant. Detailed information can be found in the "Motor selection/Motor data

"

chapter. ( 135)

Depending on the motor manufacturer, proceed as follows:

Lenze motor:

Selecting a motor from the motor catalogue in the

»Engineer«

- or -

1.Set the motor nameplate data

2.Automatic motor data identification

Third party manufacturer's motor:

1.Set the motor nameplate data

2.Automatic motor data identification

or set known

equivalent circuit diagram manually:

C00084

: Motor stator resistance

C00085

: Motor stator leakage inductance

3. Set speed switching thresholds between open-loop and closed-loop controlled operation:

• Set transition speed from closed-loop to open-loop operation in C00996/1

in [%] with regard to the rated

motor speed (C00087

).

• Set transition speed from closed-loop to open-loop operation in C00996/2

in [%] with regard to the rated

motor speed (C00087

).

Tip!

• With voltage-adjusted motors, a speed switching threshold of 10 % is recommended.

• As a rule of thumb, the speed switching threshold should be selected as follows:

4. Set open-loop accelerating current in C00995/1

in [%] with regard to the rated motor current (C00088).

• This value defines the height of the current that is injected during the acceleration process.

• The accelerating current must be dimensioned so that the required torque in the lower speed range can

always be reached (acceleration torque + load torque):

5th Set open-loop steady-state current in C00995/2

in [%] with regard to the rated motor current (C00088).

• This value defines the height of the current for processes without acceleration (e.g. standstill or constant

setpoint speed ).

6. For improving the operating characteristics:

If required, adapt the filter time for reconstructing the rotor position and the actual speed value through the

motor model in C00998/1

and C00998/2.

• We recommend using the Lenze setting:

Filter time rotor position (C00998/1

) = 3 ms

Filter time actual speed value (C00998/2

) = 5 ms

• Deviant from this, the following value range can be used:

Filter time rotor position (C00998/1

) = 2...5ms

Filter time actual speed value (C00998/2

) = 3...8ms

6. For protecting the motor from demagnetisation:

Set the ultimate current in C00939

.

Note!

The Lenze settings of the current controller are predefined for a power-adapted motor.

For an optimal drive behaviour of a synchronous motor, we recommend to adapt the

controller settings.

C00996/1...2 [%]

U

Rated, motor

[V]

U

Rated, FI

[V]

---------------------------------------

10⋅=

C00995/1 [%]

M

Meax

[Nm]

M

Rated

[Nm]

-------------------------------

I

Rated, motor

[A] 1.3⋅⋅=

Loading...

Loading...