Lenze · 8400 HighLine · Reference manual · DMS 12.0 EN · 06/2017 · TD23 1340

17 Function library

17.1 Function blocks | L_Curve_3

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

17.1.69.1 Use of the L_Curve_3 for tensile force characteristic

In case of centre winders, the drive torque is transmitted from the centre via the individual layers

up to the winder surface. In case of smooth materials and high diameter areas, it is mostly required

to reduce the tensile force depending on the diameter.

The FB L_Curve_3 can be used to generate a tensile force profile depending on the diameter. For this

purpose, the selection "4: Out = f(characteristic)" has to be set in C01030/1

.

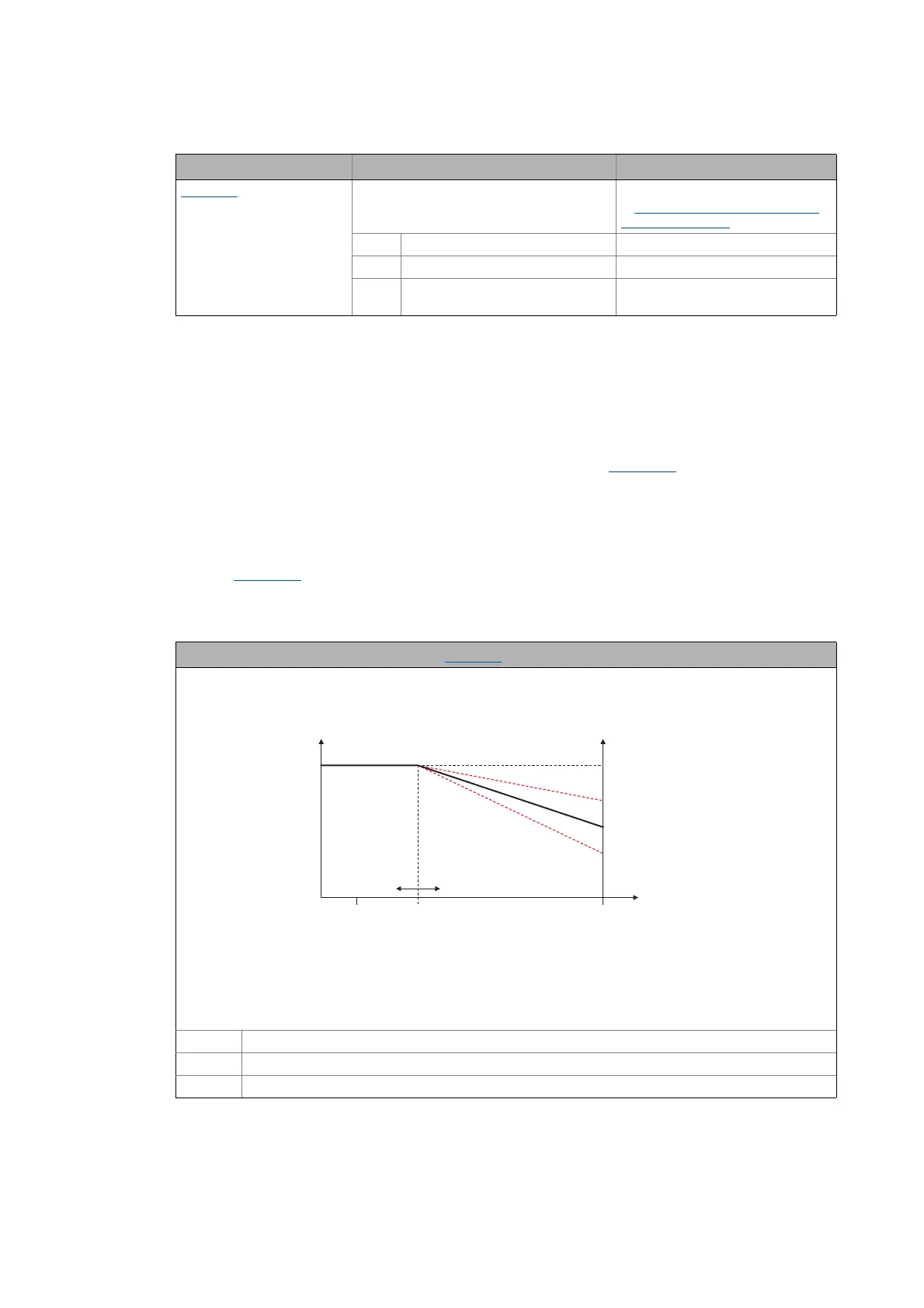

The characteristic is marked by an initial range with constant evaluation (100 %) and a second range

where the tensile force is adapted to the diameter.

The part of the characteristic that depends on the diameter can be generated for a linear tensile

force profile, a linear torque profile or based on a specified characteristic. The respective selection is

made in C01035/1

.

Linear tensile force profile

• nD0_a serves to define at which diameter the tensile force decrease is to start.

C01035/1

(from V12.00.00)

Selection of the tensile force profile

Use of the L_Curve_3 for tensile

force characteristic

0 Linear tensile force profile Lenze setting

1 Linear torque profile

2 Tensile force profile according to

characteristic

Parameters Possible settings Info

Characteristic for a linear tensile force profile (C01035/1 = 1)

Characteristic

Tensile force

Diameter

Function for D > D0:

D Current diameter (nDiameter_a)

D0 Initial point for diameter dependency (nD0_a)

HW Tensile force valuation (nCurveCtrl_a)

DMin

(DMax)

100 %

D0

0%

100 %

HW

100 %

nCurveCtrl_a = 50 %

100 %

DD0–

100 % D0–

-----------------------------

– 100 % HW–()⋅

Loading...

Loading...