Fuel Pump

90-8M0050731 MAY 2011 Page 3A-7

NOTE: Before proceeding with the system vacuum test, confirm that the lift pump is capable of delivering the required vacuum.

To do this:

a. Pinch off (restrict) the fuel supply hose between the vacuum gauge and the fuel tank.

b. The vacuum gauge reading should exceed 2.5 in. Hg. If the lift pump fails to reach 2.5 in. Hg, replace the lift pump

assembly.

c. Release the restriction.

d. Continue with the system vacuum test.

8. Observe the clear fuel line for air bubbles.

9. The vacuum gauge reading should be within the listed specification when the pump is active.

NOTE: A vacuum reading above the listed specification is an indication of a restriction between the gauge and the fuel supply.

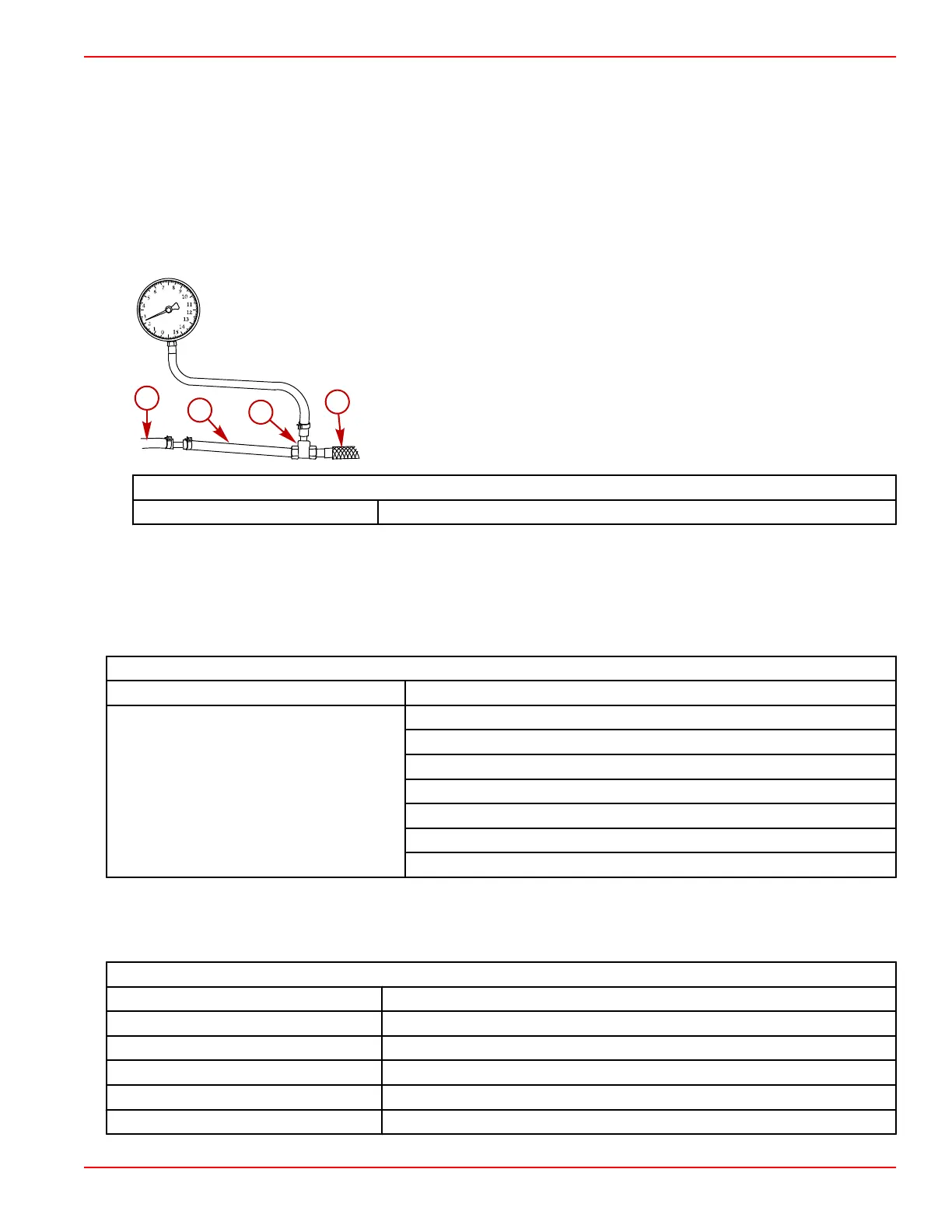

a - Engine fuel line

b - Clear fuel line

c - T‑fitting

d - Boat fuel line

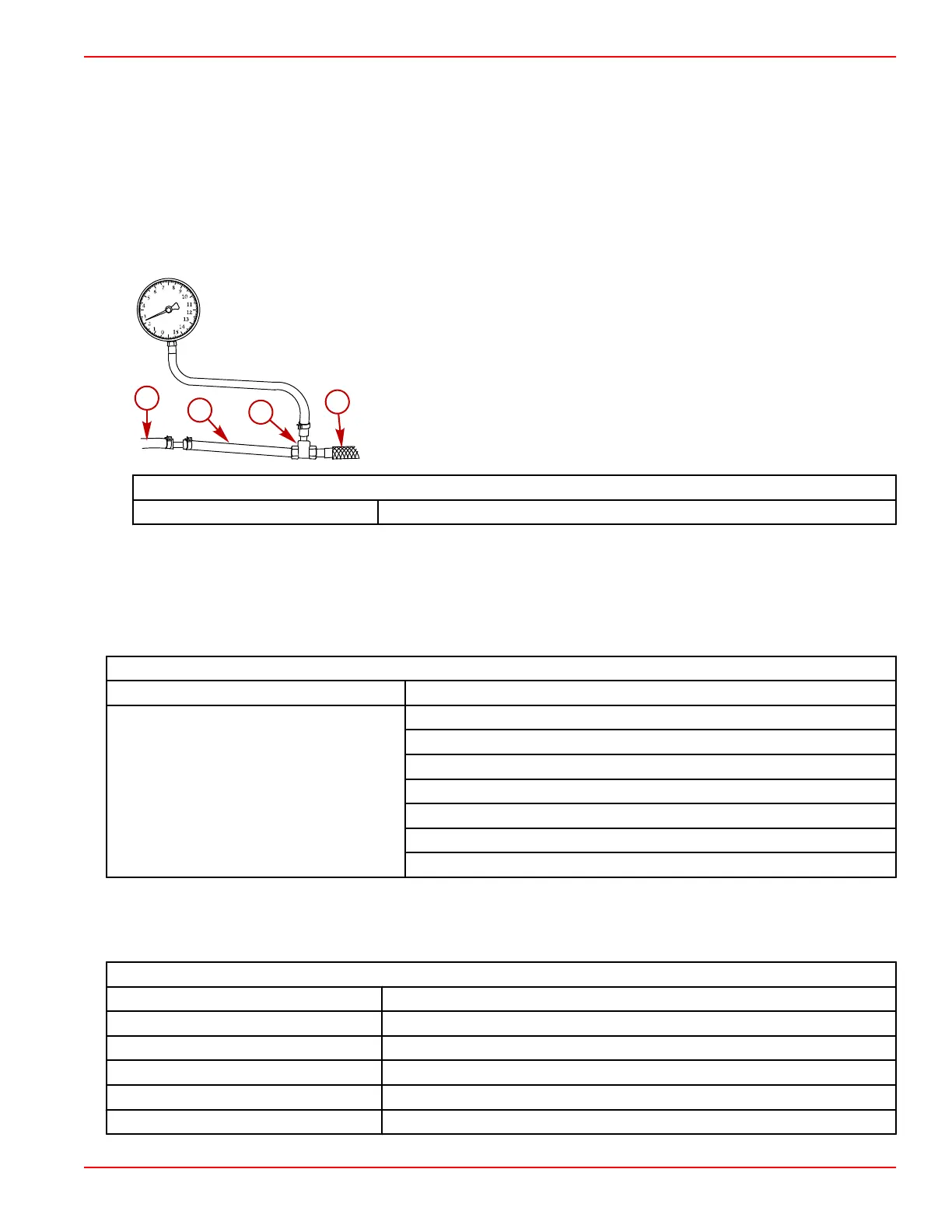

Fuel Lift Pump Vacuum

At idle 8.4 kPa (2.5 in. Hg)

Fuel Lift Pump/System Troubleshooting

Vacuum Test

This test is normally performed at idle speed. As engine speed increases, vacuum increase slightly. The increased vacuum reading

should not exceed the specification.

Vacuum Test

Normal reading Less than 2.5 in. Hg of vacuum

Reading greater than 2.5 in. Hg of vacuum

Restricted anti‑siphon valve

Restriction within the primer bulb

Kinked or collapsed fuel hose

Plugged water separating fuel filter (in the boat)

Restriction in fuel line through‑the‑hull fitting

Restriction in fuel tank switching valves

Plugged fuel tank pickup screen

Pressure Test

Install a clear fuel hose between the fuel pump and VST. Run the engine, and inspect the fuel passing through the hose for air

bubbles.

Problem: Air bubbles in the fuel line

Low fuel in tank. Fill tank with fuel.

Loose fuel line connection. Check and tighten all connectors.

Fuel pump fitting loose. Tighten fitting.

A hole or cut in fuel line. Check condition of all fuel lines and replace.

Fuel pump anchor screw loose. Tighten all screws evenly and securely.

Fuel pump filter cover anchor screw loose. Tighten screws securely.

a

b

c

d

4439

Loading...

Loading...