Powerhead

90-8M0050731 MAY 2011 Page 4A-43

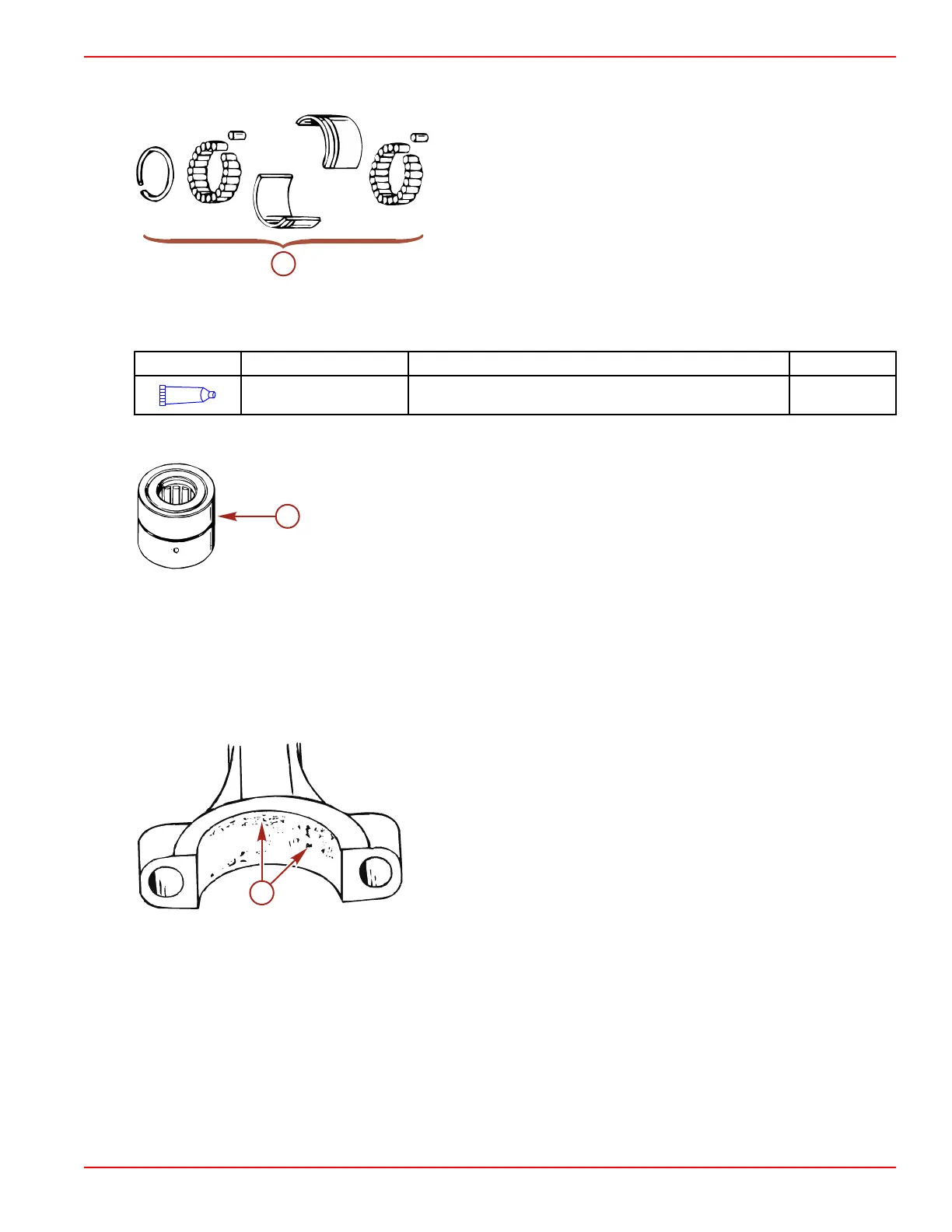

4. Thoroughly inspect the center main roller bearing. Replace the bearings if they are rusted, fractured, worn, galled, or badly

discolored.

a - Center main roller bearing

5. Clean and dry the crankshaft roller bearing that is installed in the upper end cap. Lubricate the bearing with 2‑Cycle Premium

Outboard Oil.

Tube Ref No. Description Where Used Part No.

14

2-cycle Premium

Outboard Oil

Main bearings 92-858021K01

6. Thoroughly inspect the upper crankshaft roller bearing. If the roller bearing is rusted, fractured, worn, galled, badly discolored,

or loose inside of the end cap, replace the end cap and roller bearing as an assembly.

a - Upper roller bearing

Connecting Rods

1. Check the connecting rods for alignment by placing the rods on a surface plate. If light can be seen under any portion of the

machined surfaces, if the rod has a slight wobble on the plate, or if a 0.051 mm (0.002 in.) feeler gauge can be inserted

between any machined surface and surface plate, replace the rod.

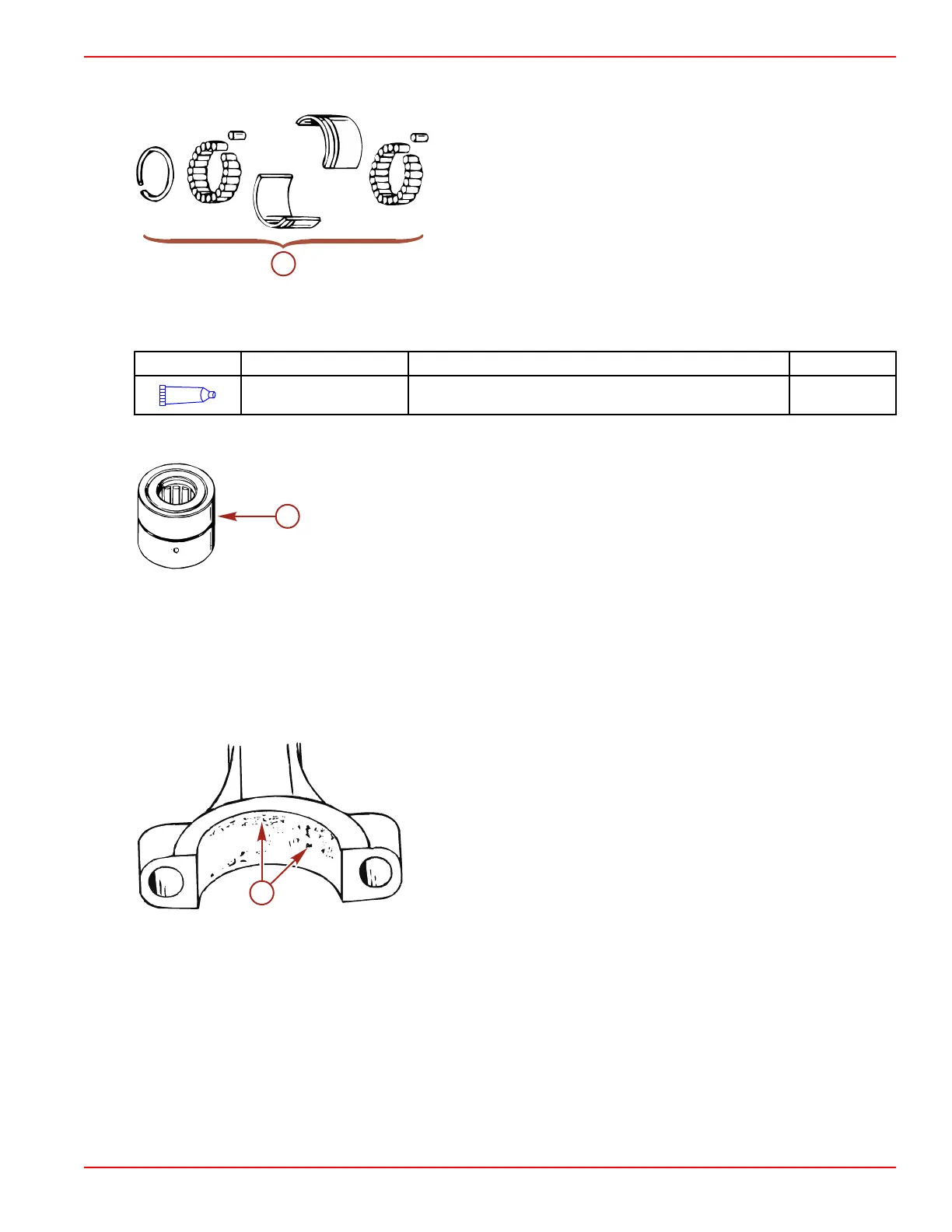

2. Check for overheating. Overheating is visible as a bluish bearing surface color caused by inadequate lubrication or excessive

RPM.

3. Check for rust. Rust formation on bearing surfaces causes uneven pitting of surfaces.

a - Pitting

Loading...

Loading...