Cooling

Page 4B-6 90-8M0050731 MAY 2011

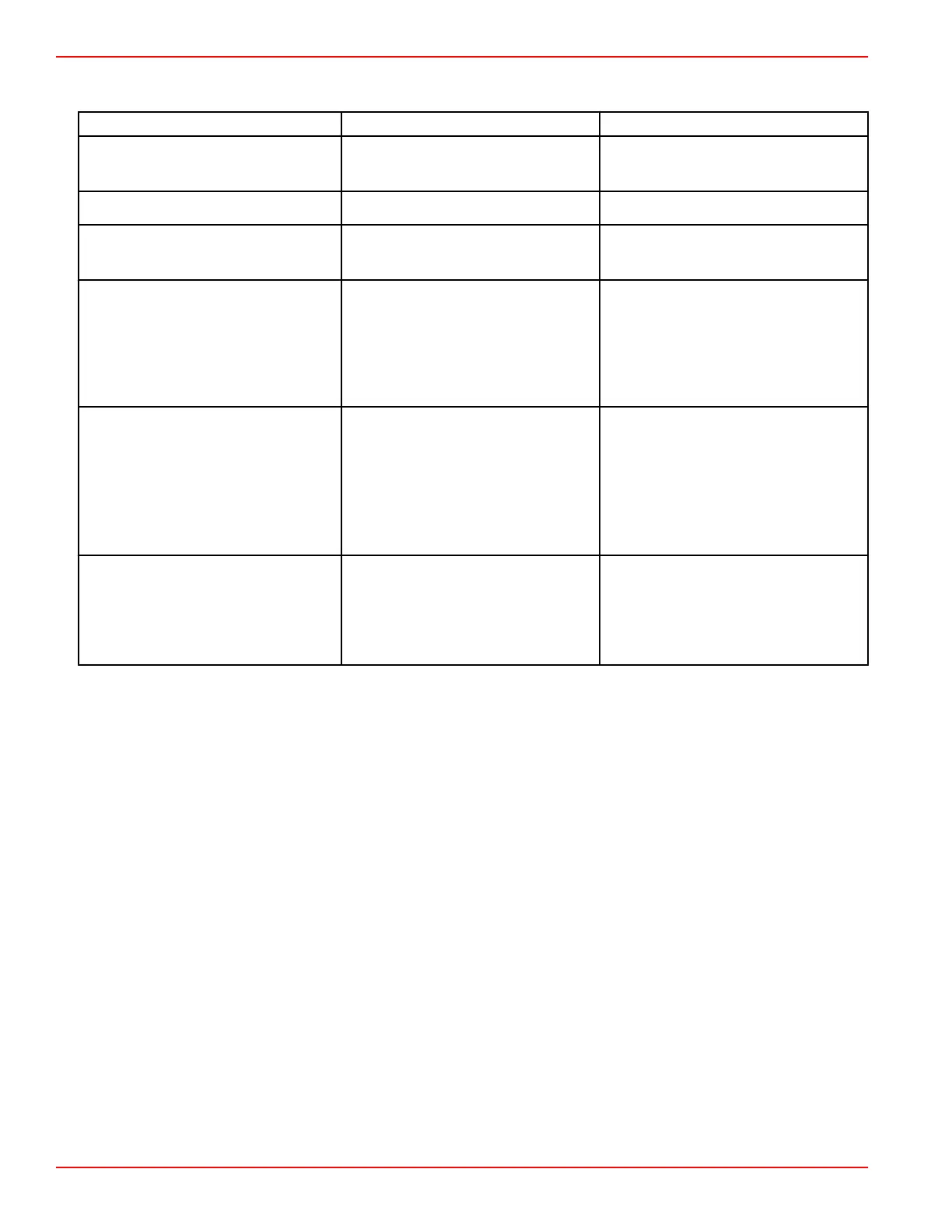

Problem Diagnosis

Condition Recommended Range Possible Cause

Pressure below specification at idle 1.4–4 kPa (0.2–0.6 psi)

• Severe internal leak

• Inlet restriction

Pressure above 34 kPa (5 psi) at idle 1.4–4 kPa (0.2–0.6 psi)

• Plugged tell‑tale

Pressure is below minimum specification

at WOT, 5500 RPM with boat on plane

69 kPa (10 psi)

• Inlet restriction

• Severe internal leak

Pressure higher than normal at WOT, but

engine still indicates overheat condition,

5500 RPM with boat on plane

Maximum pressure ‑ 103 kPa (15 psi)

• Outlet water passages restricted

• Steam pocket has formed at top of

powerhead due to lack of cooling

water

• Kinked hose ‑ expansion chamber to

adapter plate

Pressure below specification at idle or

WOT

• Pinched/kinked/leaky hose from

exhaust cover to water pressure

sensor

• Plugged fitting on exhaust cover

• Wire harness connection at water

pressure sensor

• Weeds or debris on impeller shaft

Exhaust hose burned ‑ expansion

chamber to muffler

• Kinked hose ‑ strainer to starboard

fuel rail

• Plugged strainer ‑ adapter plate

• Kinked hose ‑ compressor to

expansion chamber

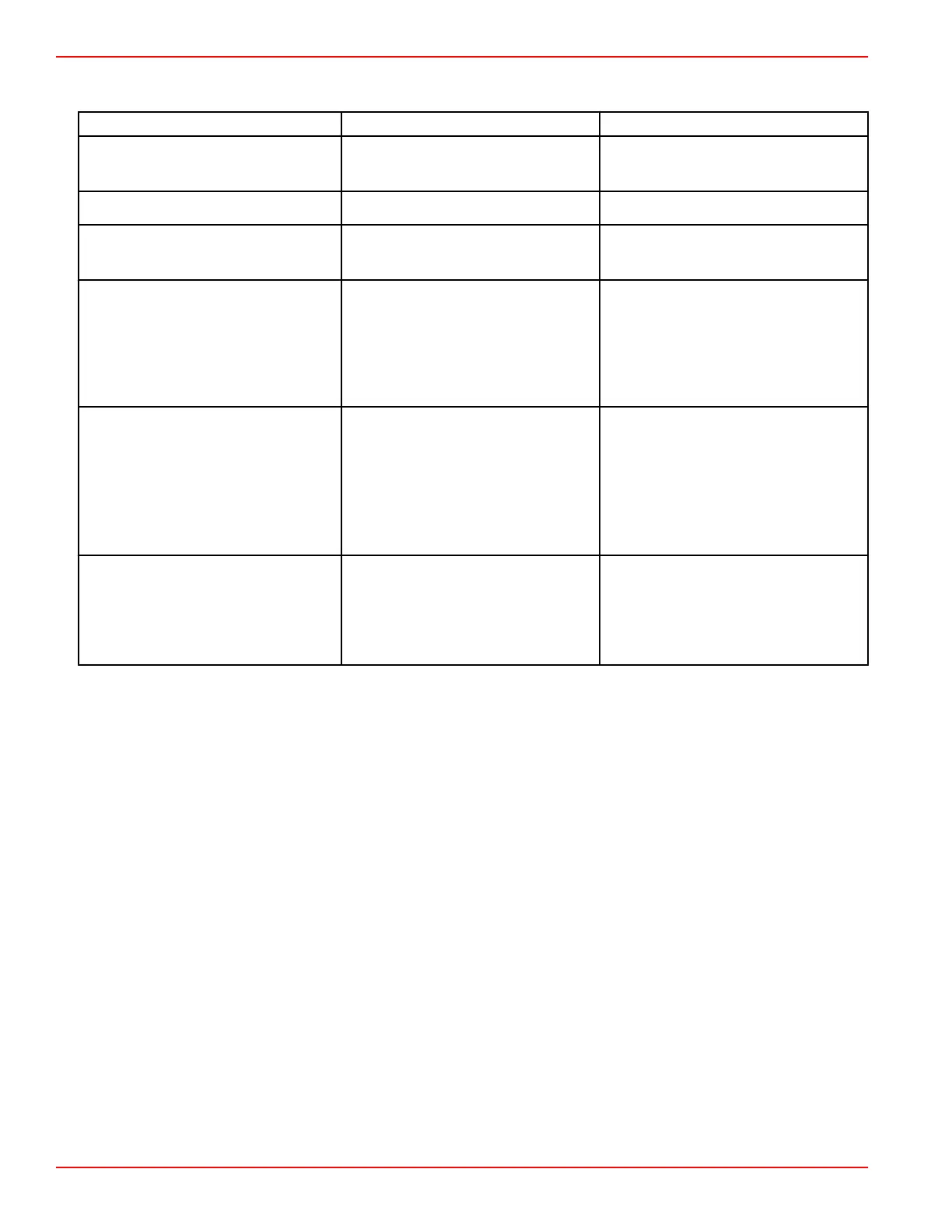

Model 200 Water Flow

Description

Water is pumped up through the adapter plate (9) and into the powerhead by the jet pump impeller which is constantly turning

whenever the engine is running. Water flows through the center of the block, around the cylinder sleeves and through the cylinder

heads (1).

Water exits from the bottom of the block and into the adapter plate (9) flowing past the exhaust runners and into the expansion

chamber. The water fills the expansion chamber and exits out the top of the chamber via a hose and back into the adapter plate

where it drains into the pump.

Water is also pumped from the starboard side of the adapter plate to the fuel cooler (13) and then to the air compressor (12). The

water exits the air compressor via a hose to a T‑fitting over the expansion chamber. The water is then sprayed into each exhaust

pipe for cooling purposes.

To allow complete passage filling and to prevent steam pockets, all cooling passages are interconnected. Small passages are

incorporated to allow the cooling system to drain.

Loading...

Loading...