Timing, Synchronizing, and Adjusting

Page 2C-4 90-8M0050731 MAY 2011

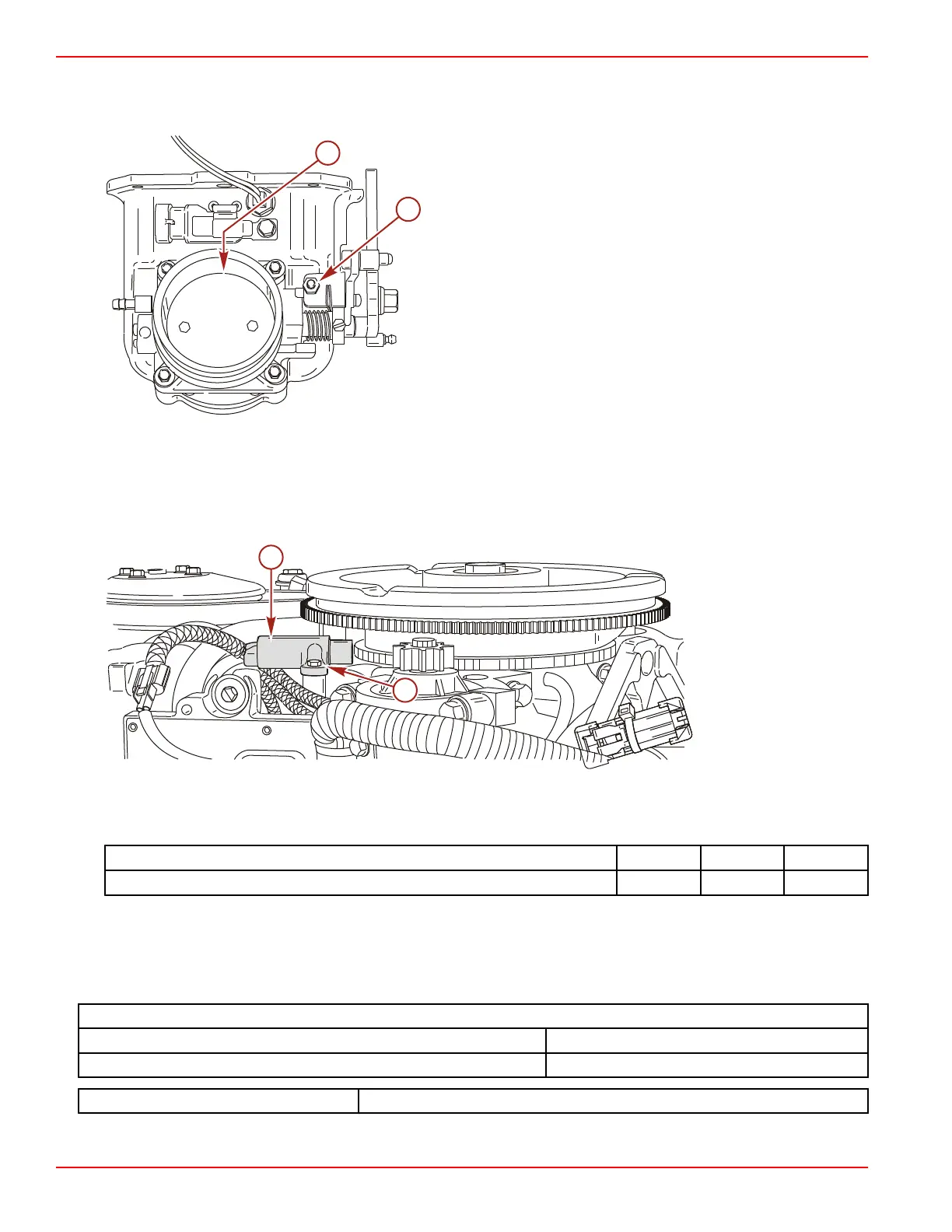

Throttle Plate Stop Screw

IMPORTANT: Do not adjust the throttle plate stop screw from the factory setting. However, should the throttle plate require

adjustment, use the throttle plate stop screw to set the throttle plate clearance to 0.7937 mm (0.031 in.) with a #68 drill bit.

a - Throttle plate stop screw

b - Throttle plate clearance

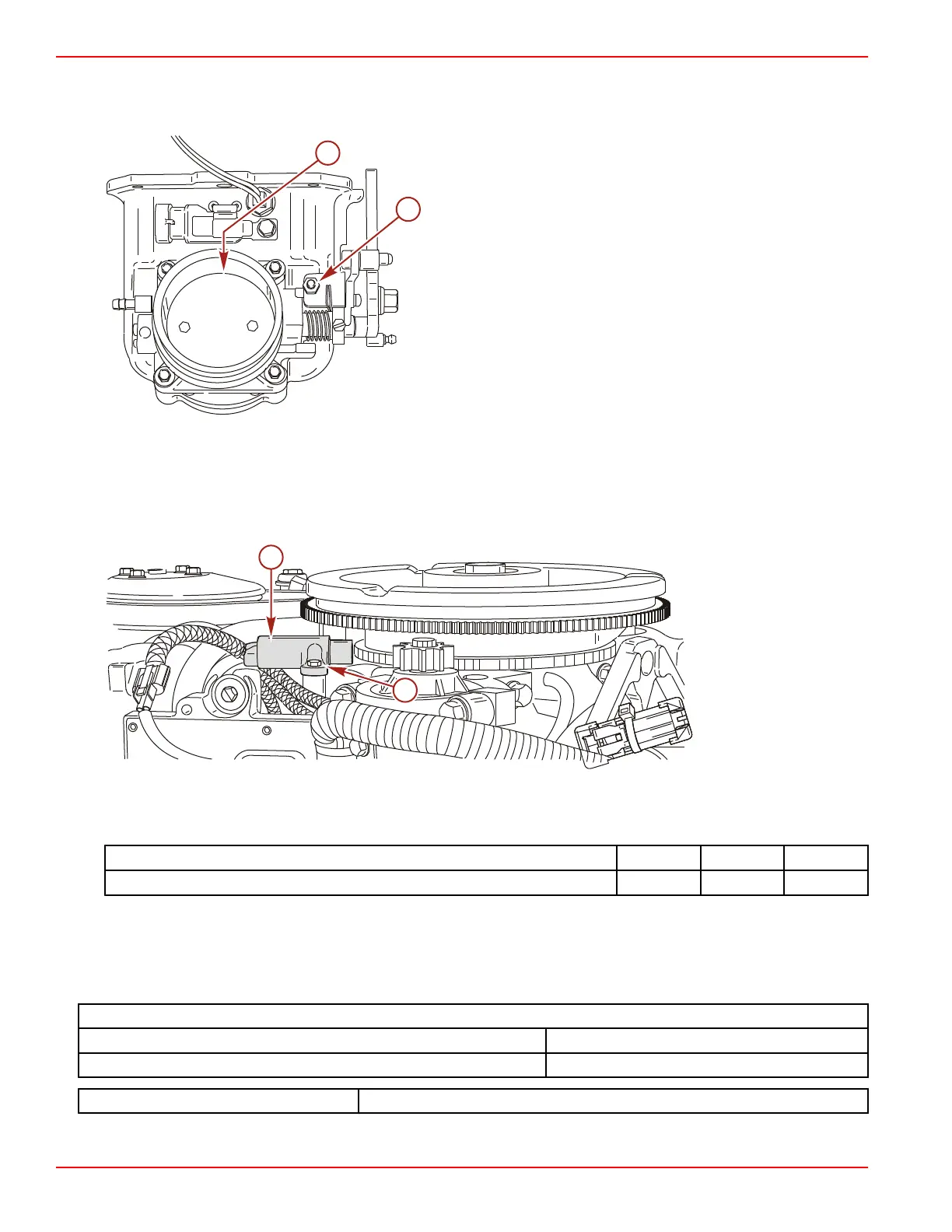

Crankshaft Position Sensor Air Gap

IMPORTANT: The crankshaft position sensor air gap (between flywheel tooth and sensor) is not adjustable. Visually inspect sensor

for damage from foreign debris. Replace sensor as required.

1. Remove flywheel cover. Refer to Section 2A - Flywheel Cover Removal and Installation.

2. Inspect for damage or debris.

a - Crankshaft position sensor

b - Bracket screw

Description Nm lb‑in. lb‑ft

Crankshaft position sensor bracket screw 5 44

3. Install flywheel cover.

Throttle Position Sensor (TPS) Adjustment

The TPS is not adjustable. The TPS position can be monitored with the computer diagnostic system. Voltage change should be

smooth from idle to wide‑open throttle. If the voltage change is erratic, the TPS is defective.

Throttle Position Sensor Specifications

Idle 0.4–1.3 VDC

Wide‑open throttle 4.0–4.7 VDC

Computer Diagnostic System (CDS) Order through SPX

Loading...

Loading...