Pump Unit

Page 5A-24 90-8M0050731 MAY 2011

Impeller Nut Socket 91‑850297

Impeller Shaft Wrench 91‑832093A 1

Inspecting the Wear Ring and Impeller

Wear Ring

1. Inspect the wear ring for excessive scoring and/or grooves. Replace the wear ring if deep grooves are present or if severe

scoring has taken place.

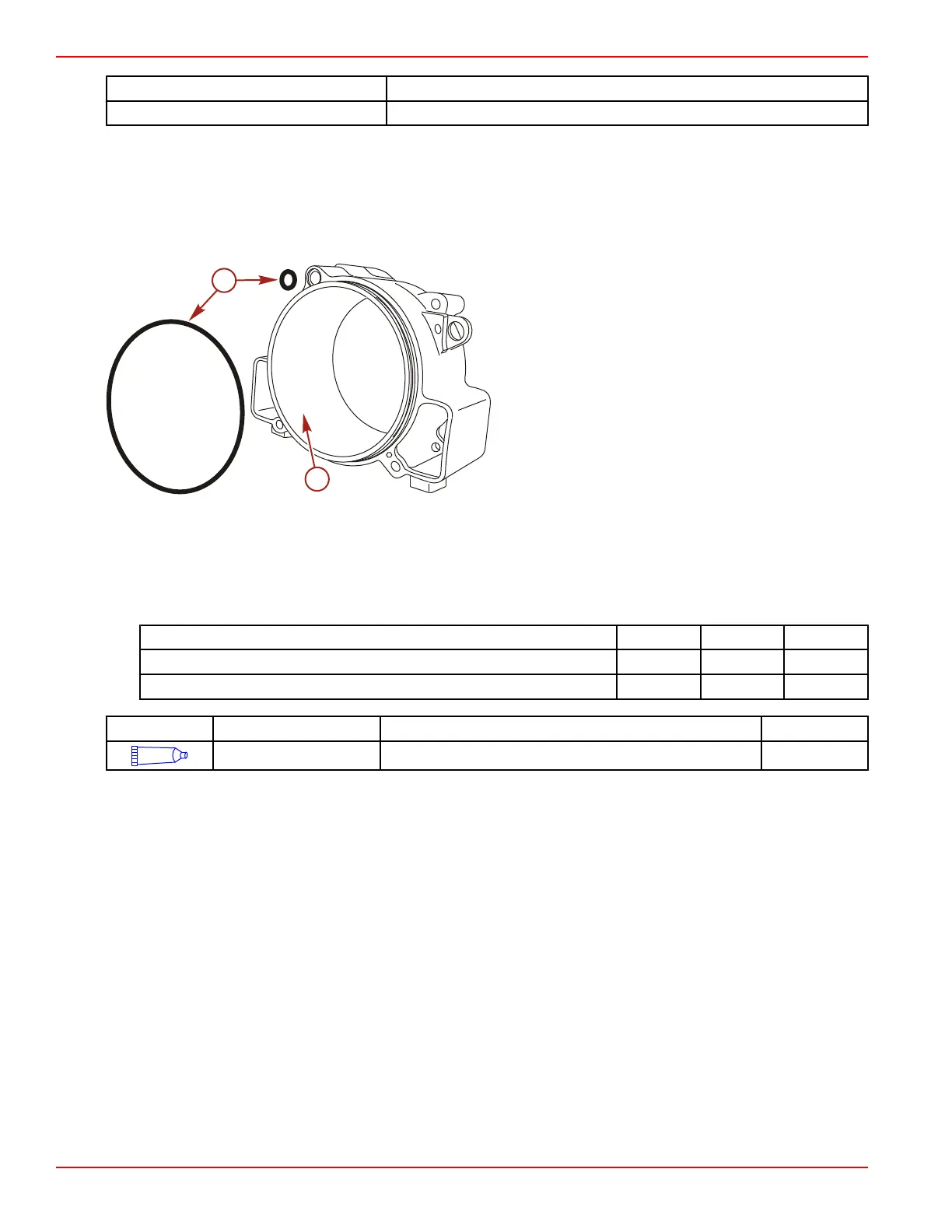

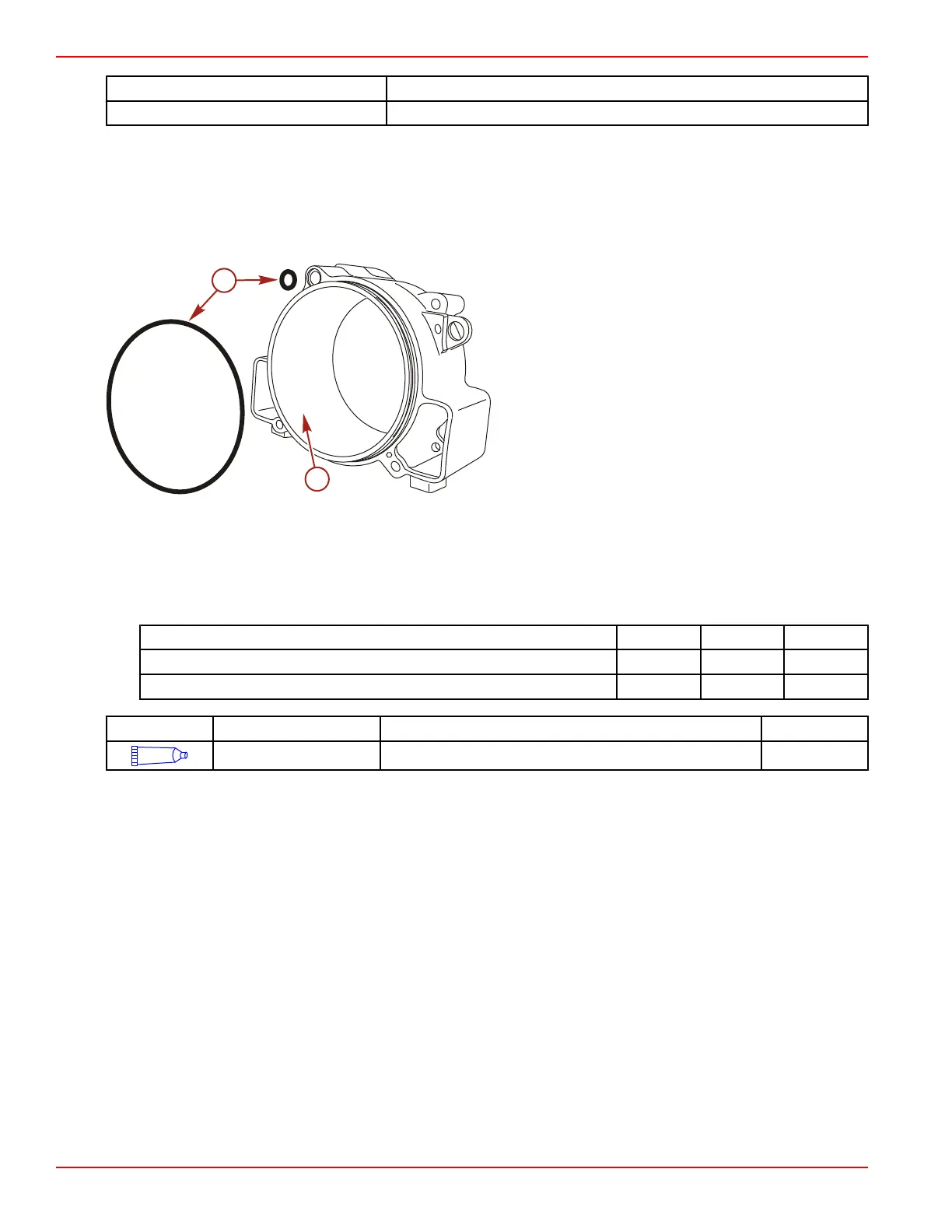

2. Ensure that the O‑ring is in the counterbore before installing the wear ring to the drive housing.

a - O‑ring

b - Wear ring surface

3. Refer to

Nozzle and Rudder Components for the following:

a. Inspect the seal in the stator for wear/damage.

b. Inspect the bellows on cables for wear.

c. Inspect the anodes, replace as necessary.

d. Inspect the pivot pins and bushings, replace as necessary. Tighten the reverse gate pivot pins and rudder pivot pins to

the specified torque. Use Loctite 271 Threadlocker on the threads.

Description Nm lb‑in. lb‑ft

Reverse gate pivot pins 68 50

Rudder pivot pins 68 50

Tube Ref No. Description Where Used Part No.

7

Loctite 271 Threadlocker Reverse gate and rudder pivot pin threads 92-809819

e. Inspect the impeller for cracks and damaged blades.

f. Inspect the stator vanes for cracks and/or damage.

Loading...

Loading...