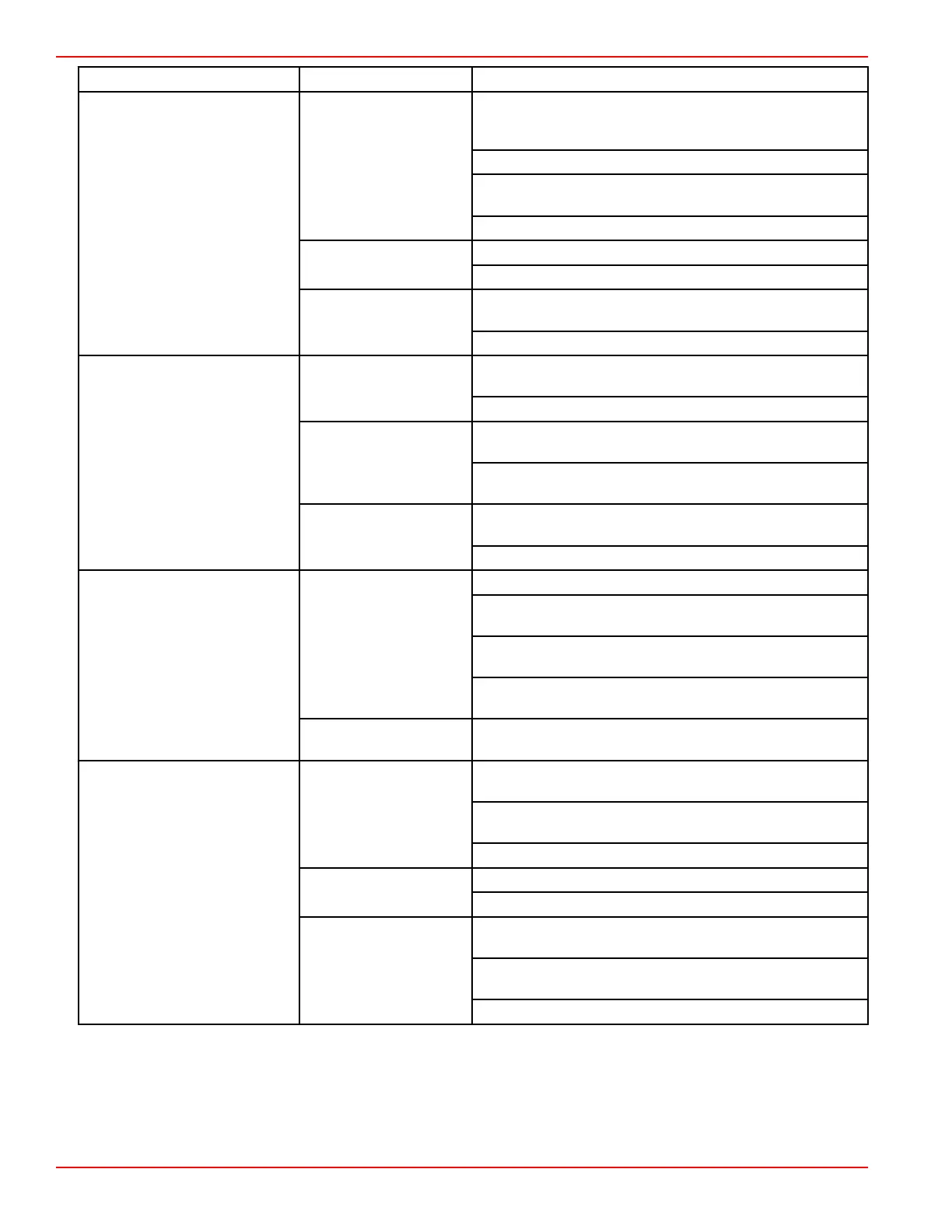

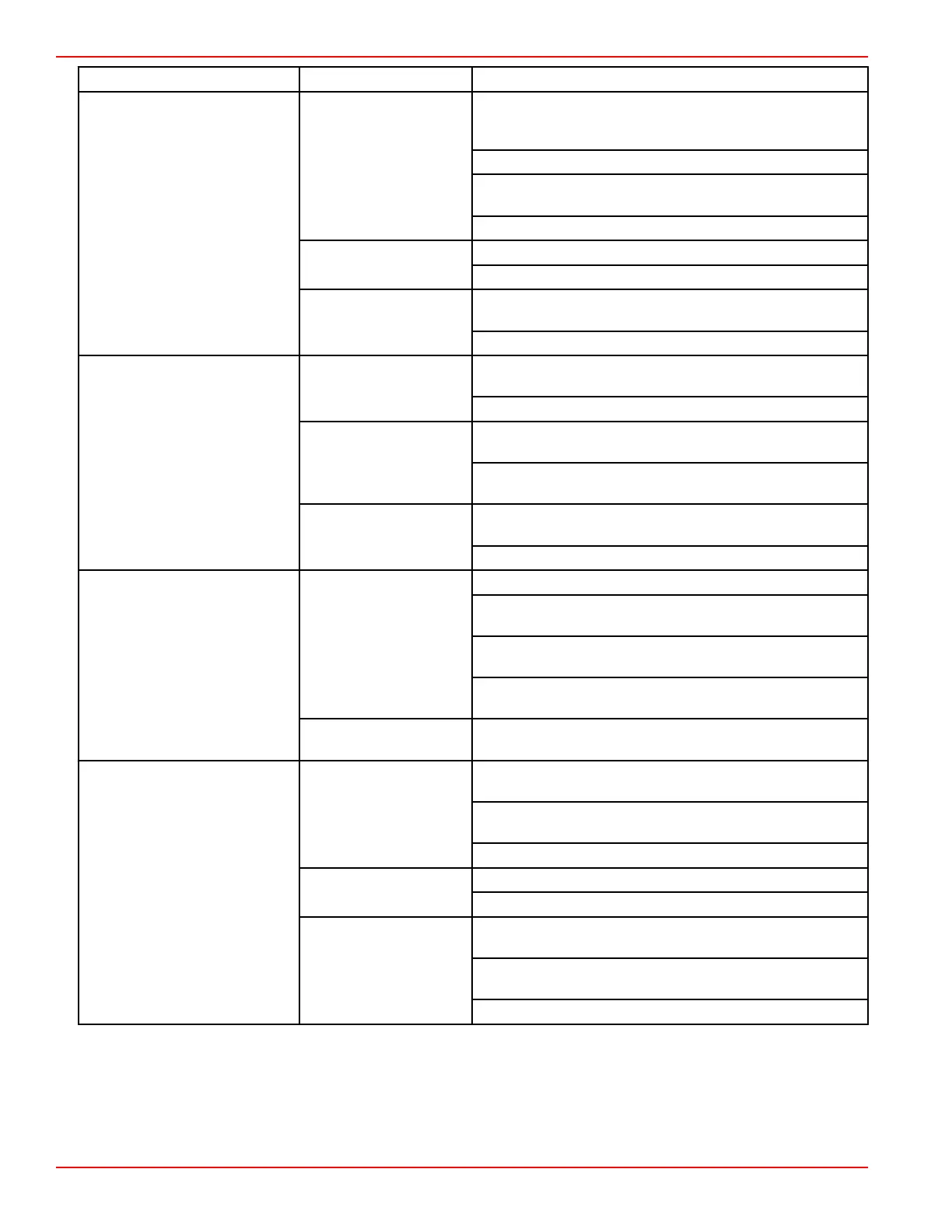

Direct Fuel Injection

Page 3B-28 90-8M0050731 MAY 2011

Component or Problem Possible Causes Corrective Action

Fuel pressure and air pressure are

both

low

Air compressor Provide 80 psi of shop air to the air rail test (Schrader) valve.

Inspect the air compressor for leaks. Leaking air through the

compressor indicated bad reeds.

Inspect for broken reeds.

Remove the air compressor cylinder head and inspect the

cylinder wall and piston for scuffing.

Replace components as necessary.

Air compressor inlet Inspect the compressor air inlet for blockage, kinks, or tears.

Clean, correct, or replace components as necessary.

Starboard rail air inlet

hose

Inspect the air inlet hose to the starboard rail for blockage,

kinks, or tears.

Clean, correct, or replace components as necessary.

Fuel pressure and air pressure are

both

low

Starboard to port rail air

transfer hose

Inspect the air transfer hose from the starboard to port rails for

blockage, kinks, or tears.

Clean, correct, or replace components as necessary.

Tracker valve Remove/inspect the tracker valve diaphragm for cuts, tears, or

abrasions.

Inspect the diaphragm seat and rail for damage. Replace

components as necessary.

Direct injector Injector may be damaged or stuck open. Perform a resistance

check or leak test to determine cause.

Check O‑ring for nicks or cuts.

Fuel pressure and air pressure are

both

low

Air regulator Provide 80 psi of shop air to the air rail test (Schrader) valve.

(This should be the last

component to check/

remove)

Visually inspect the air regulator cover. If air is escaping through

the small hole, the regulator is faulty. Replace the port fuel rail.

If necessary, remove/inspect the air regulator diaphragm for

cuts, tears, or abrasions.

Inspect the diaphragm seat and rail for damage. If the air

regulator is faulty, replace the port fuel rail.

Air rail test (Schrader)

valve

Damaged valve. Replace the valve with an Air Valve Kit.

Fuel pressure is low or fuel

pressure drops while running

Tracker valve Remove/inspect the tracker valve diaphragm for cuts, tears, or

abrasions.

Air pressure remains normal Inspect the diaphragm seat and rail for damage. Replace

components as necessary.

Check the air system for fuel contamination.

Fuel hoses Inspect the fuel hoses for blockage, kinks, or tears.

Clean, correct, or replace components as necessary.

Fuel regulator Remove/inspect the fuel regulator diaphragm for cuts, tears, or

abrasions.

Inspect the diaphragm seat and rail for damage. If the fuel

regulator is faulty, replace the port fuel rail.

Check the air system for fuel contamination.

Loading...

Loading...