Powerhead

Page 4A-48 90-8M0050731 MAY 2011

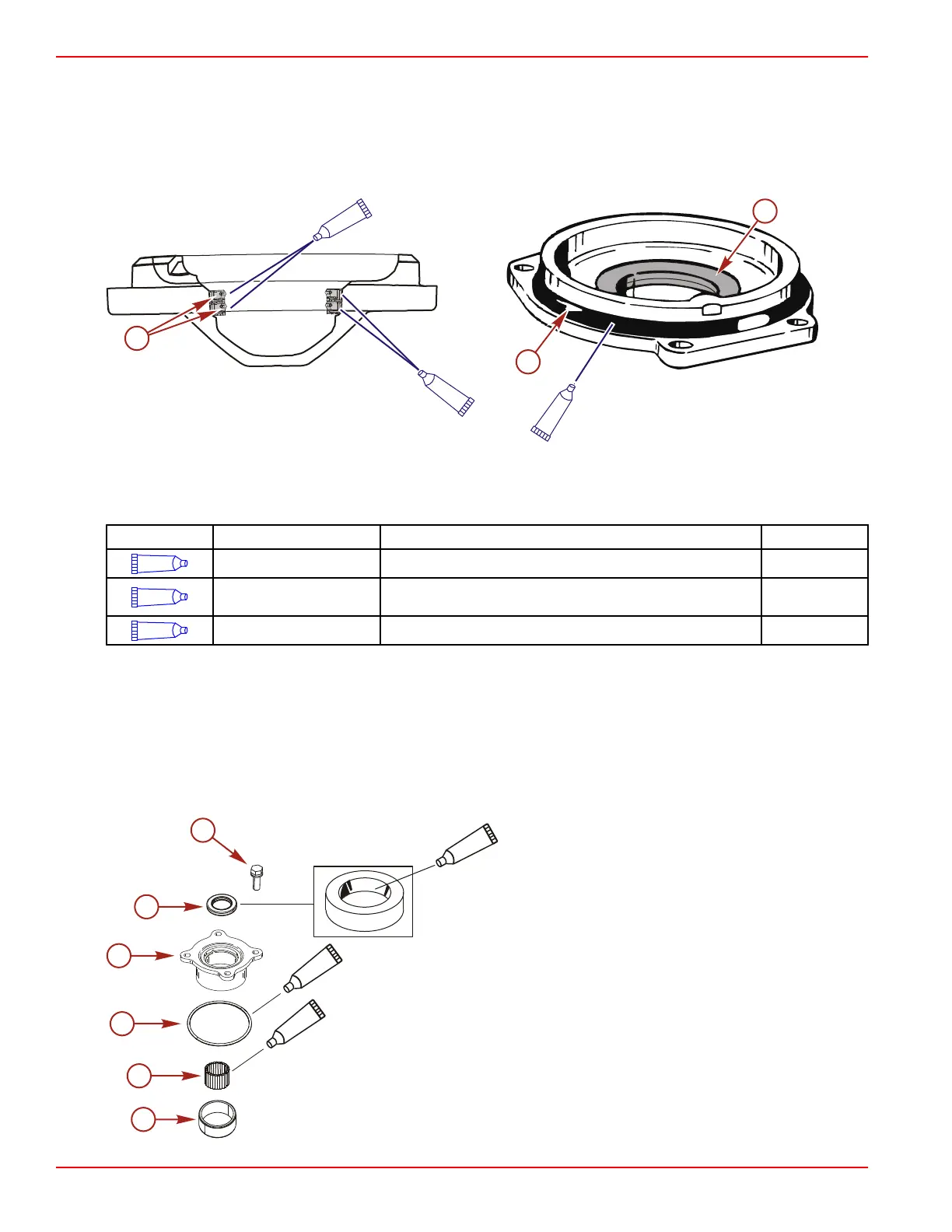

b. Use a suitable mandrel to press one oil seal (lip facing down) into the lower end cap until firmly seated. Remove any

excess Loctite.

c. Press the second oil seal (lip facing down) until firmly seated on the first oil seal. Remove any excess Loctite.

d. Lubricate the oil seal lips with 2‑4‑C with Teflon.

e. Lubricate the O‑ring seal surface on the end cap with 2‑Cycle Premium Outboard Oil.

f. Install the O‑ring over the lower end cap.

a - Oil seal

b - O‑ring

Tube Ref No. Description Where Used Part No.

7

Loctite 271 Threadlocker Lower end cap oil seals 92-809819

14

2-cycle Premium

Outboard Oil

O-ring seal surface of end cap 92-858021K01

95

2-4-C with Teflon Oil seal lips 92-802859A 1

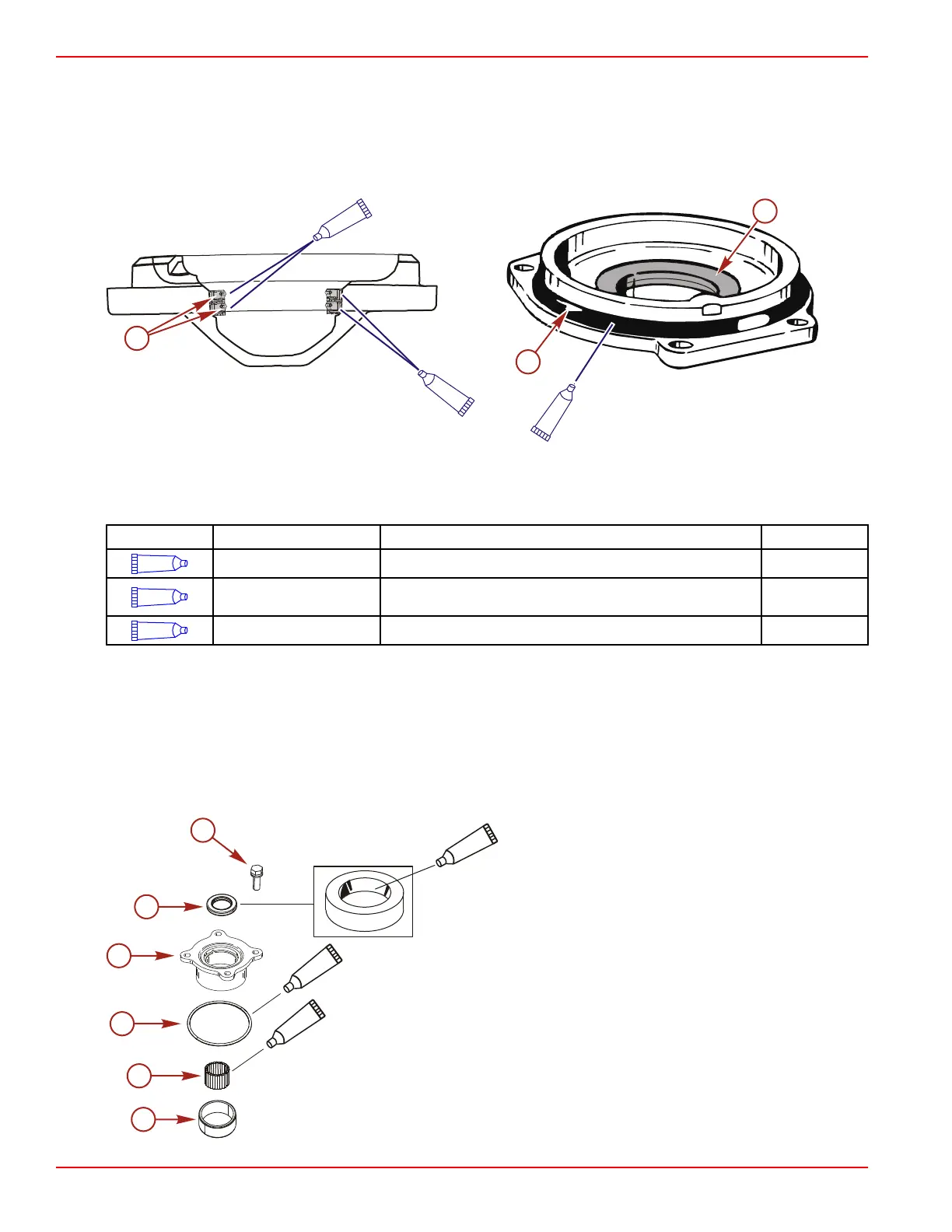

12. Install the oil seal into the upper end cap bearing carrier as follows:

a. Apply a light film of 2‑4‑C with Teflon to the outer diameter of the upper end cap oil seal. This eases the seal into the

carrier.

b. Lubricate the oil seal lip with 2‑4‑C with Teflon.

c. Using a suitable mandrel, press the oil seal into the bearing carrier (lip facing down) until bottomed out on the shoulder

of the carrier.

d. Lubricate the O‑ring seal surface on the end cap with 2‑4‑C with Teflon and install on the carrier.

e. Lubricate the roller bearing with 2‑Cycle Premium Outboard Oil.

a - Screw (0.312‑18 x 1.00 in.)

b - Seal (lip faces down)

c - End cap

d - O‑ring

e - Roller bearing

f - Race

Loading...

Loading...