2-11

ADJUSTING THE BLADE AND THE PEN

Adjusting procedure for the blade of the tangential cutter, reciprocal cutter holder and the swivel cutter is

given below.

For the applicable blade of each holder, see page A.18.

Cutter holders 4N and 10N (for unit C)

Cutter holders 4N and 10N are tangential cutters used for the C unit.

The procedure for taking out the carbide blade 30° or the high-speed steel blade 30° of cutter holder 4N is described

below.

Carbide blade 30°.................... For hard works such as industrial rubber and packings

High-speed steel blade 30° ...... For light-weight and soft works such as coated board and corrugated fiberboard.

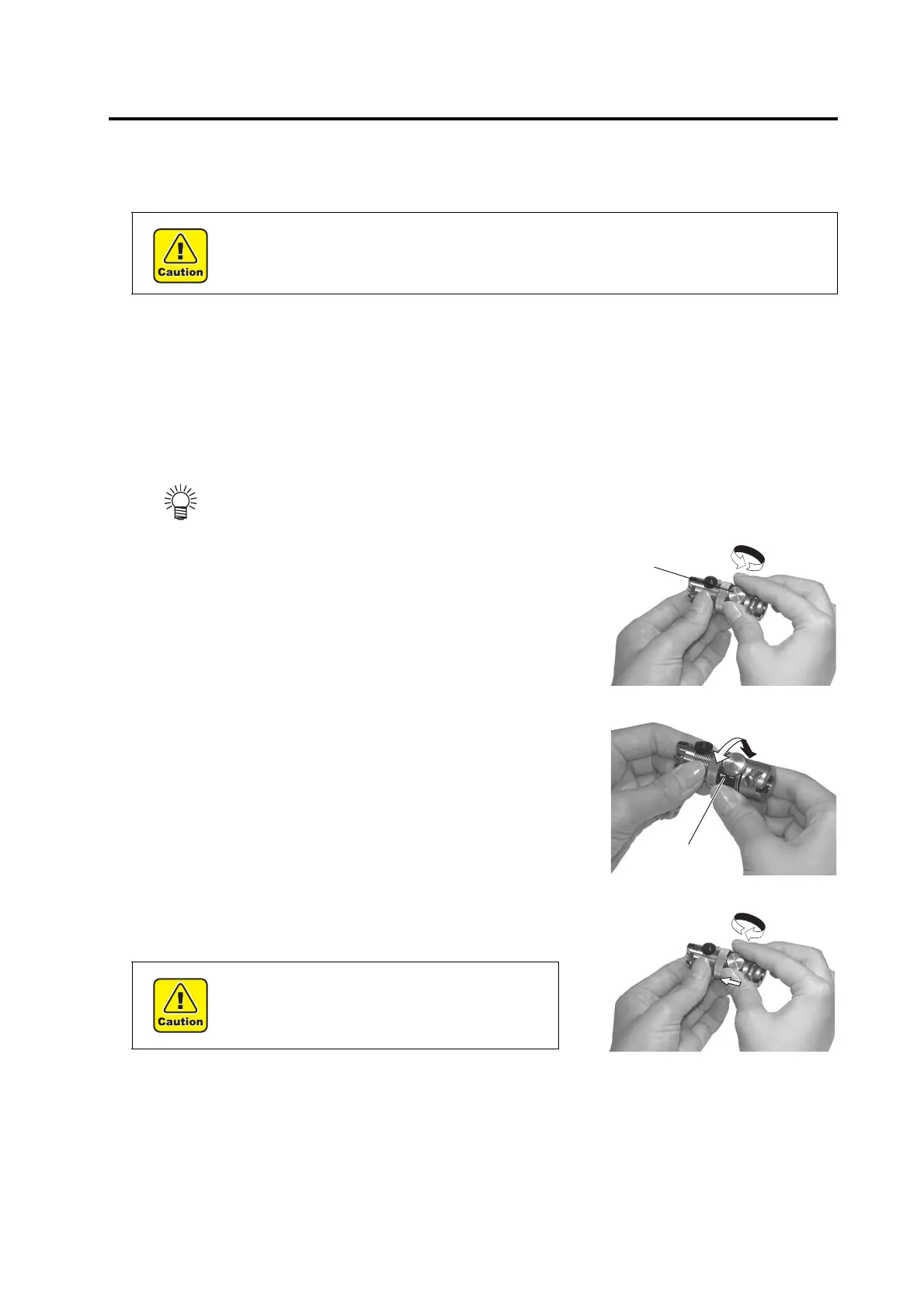

1. Loosen the dial stopper.

Loosen the dial stopper counterclockwise to loosen it.

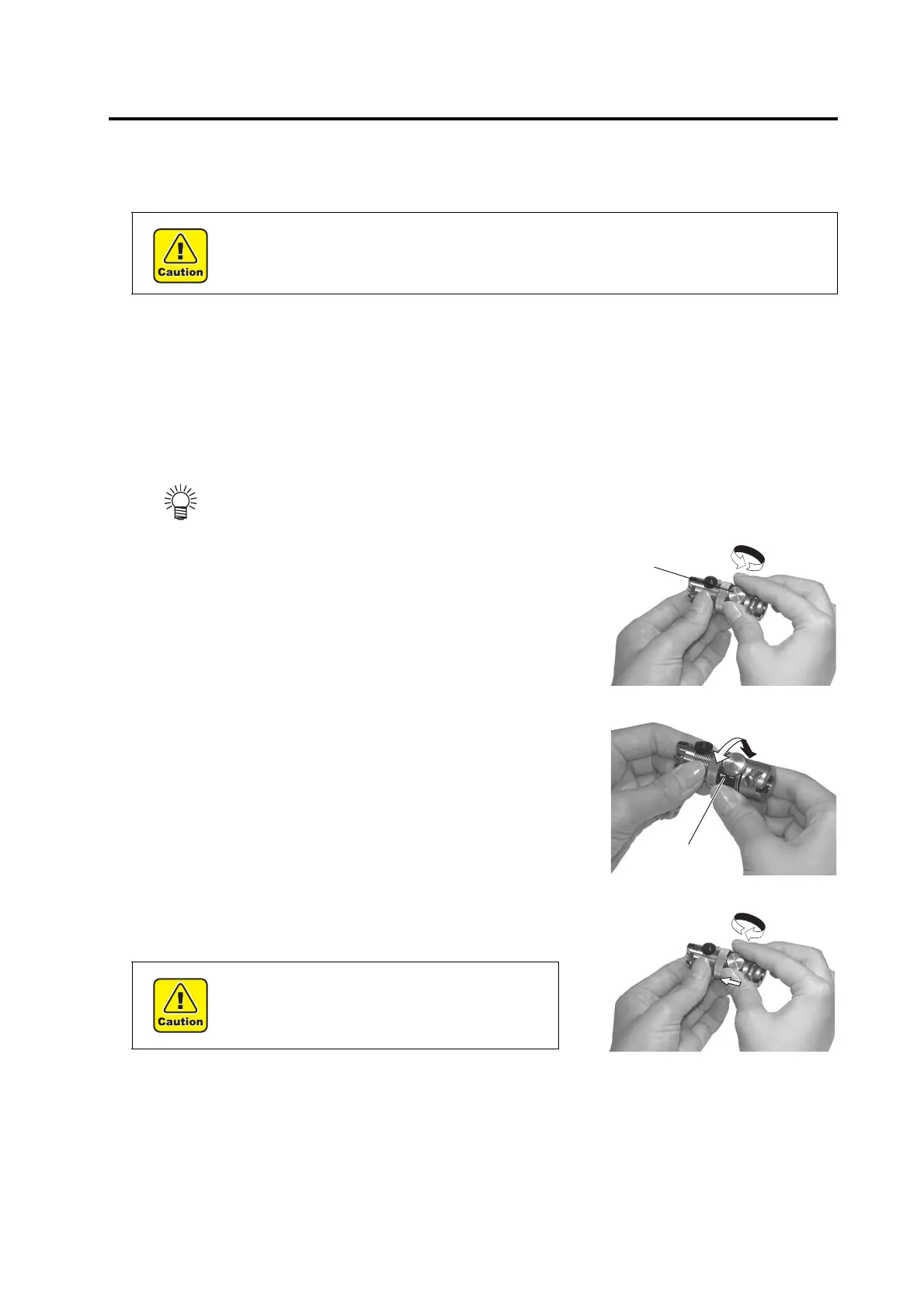

2. Turn the dial.

If you turn the dial in the direction of the arrow, the blade tip will

protrude by 0.1 mm.

Projecting amount of the blade tip to be used as a guide:

Thickness of work + 0.2 mm

3. Pressing the dial in the direction of the arrow, tighten

the dial stopper.

• Proceed with care to avoid getting injured by the blades.

Use the supplied pin set to be safe.

• Special blades and holders for tangential cutters are prepared in accordance with works. Please

contact your local dealer or MIMAKI office for details.

• The dial has a play. To eliminate an error in the

projecting amount of the blade tip, tighten the

dial stopper while keeping the dial held pushed

in the direction of the arrow.

Loading...

Loading...