CHECKING CUTTING CONDITIONS [TEST CUT]

2-31

Checking the status of tools

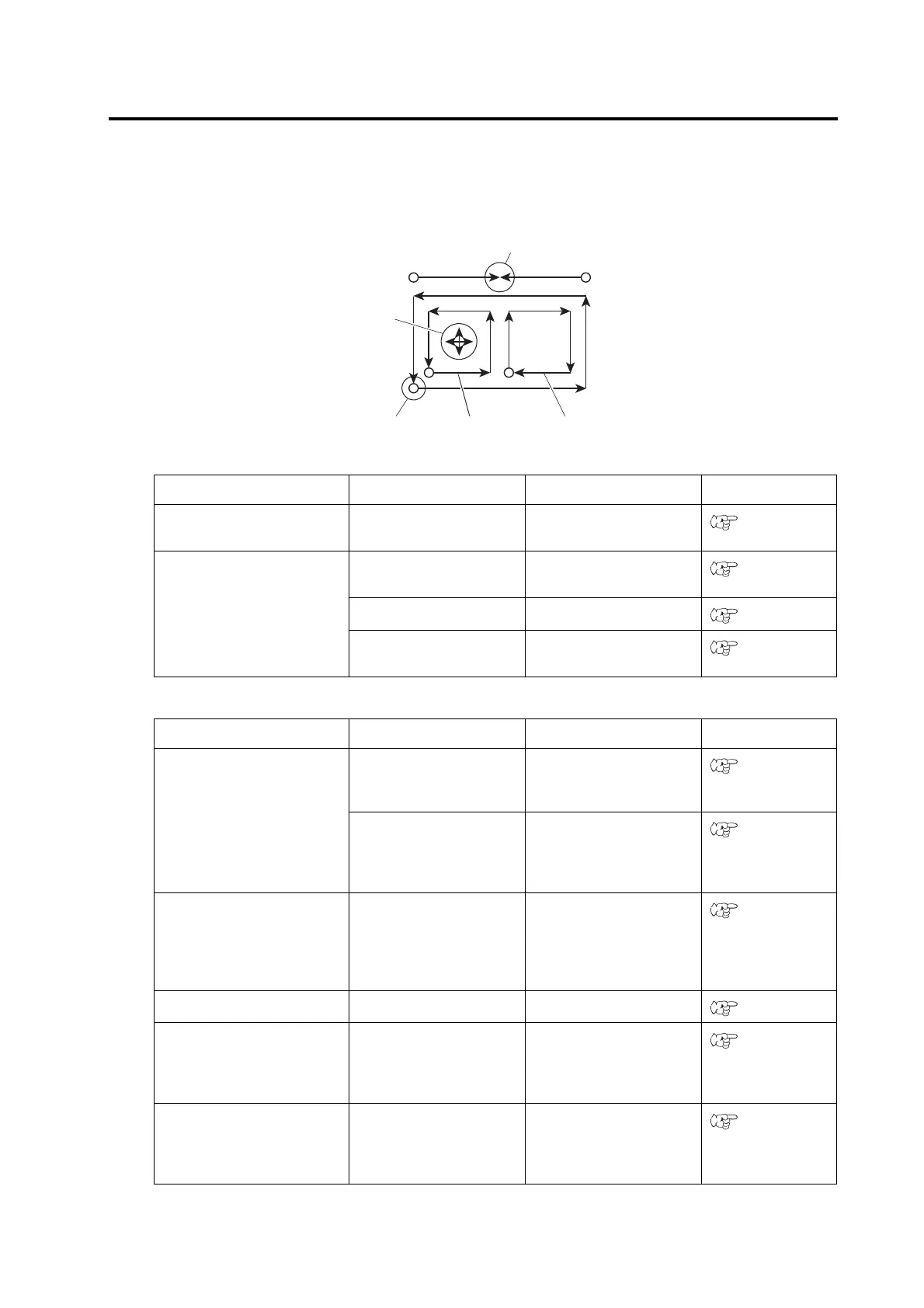

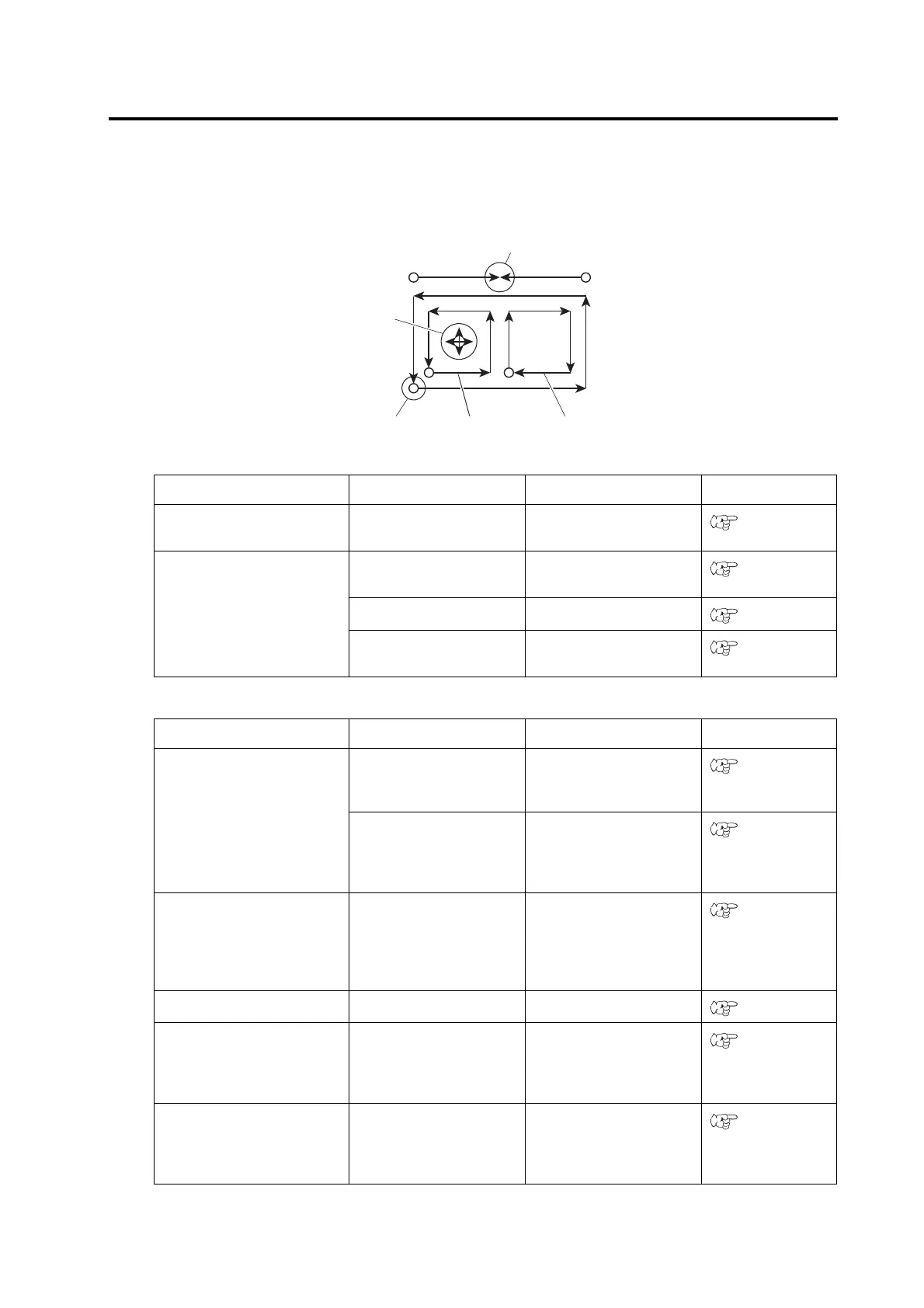

Execute the [TEST CUT] function with the tools specified using the tool selecting function. Items to be checked for

the tools are shown in the tables below.

Pen

Tangential cutter

Check point Cause Corrective measure Reference page

Lines fail to meet at point A. Pen not securely installed. Securely tighten the screw

in the holder.

P. 2-15

Dots or thin spots are made. Ink has run out. Replace the pen with a new

one.

P. 2-15

The pressure is insufficient. Increase the pressure.

P. 2-25

The speed is so high that the

pen rises above the work.

Decrease the speed.

P. 2-25

Check point Cause Corrective measure Reference page

Lines fail to meet at point A.

Set value for the [END

CORRECTION] is too

small.

Set a larger value for the

[END CORRECTION].

P. 2-25

The cutter is off-center. Conduct the “adjustment of

the eccentricity” that is one

of the tool adjusting func-

tions.

P. 3-6

Line at point A is out of posi-

tion

The tangential cutter is

defective in terms of θ

angle.

Carry out the “adjustment

of the θ angle” that is one of

the tool adjusting functions.

A part of the work remains

uncut.

P. 3-8

The work remains uncut. The pressure is insufficient. Increase the pressure.

P. 2-25

A corner of the work remains

uncut.

Set value for the [START

CORRECTION] and that

for the [END CORREC-

TION] are too small.

Set a larger value respec-

tively for the [START

CORRECTION] and the

[END CORRECTION].

P. 2-25

D and D’ are different in size. The cutter is off-center. Conduct the “adjustment of

the eccenticity” that is one

of the tool adjustig func-

tions.

P. 3-7

PointA

PointC

PointD

PointDʼ

Loading...

Loading...