3-12

How to adjust:

Follow the adjusting procedure given below.

How to adjust the tools

“TOOL SELECT” consists of two categories; i.e., the “adjustment of the cutter”, the “adjustment of the roller” and

“circle q adjust”.

The tool adjusting procedure is described below taking the “adjustment of the cutter 1” as an example.

1. Attach a pen and a tangential cutter to the head.( P. 2-15, P. 2-16)

2. Press the key several times until the LCD indicates

page 4 of the LOCAL MENU.

3. Select the [TOOL ADJSUT].

4. Select the [CUTTER ADJUST].

The menu changes to the eccentricity adjustment menu.

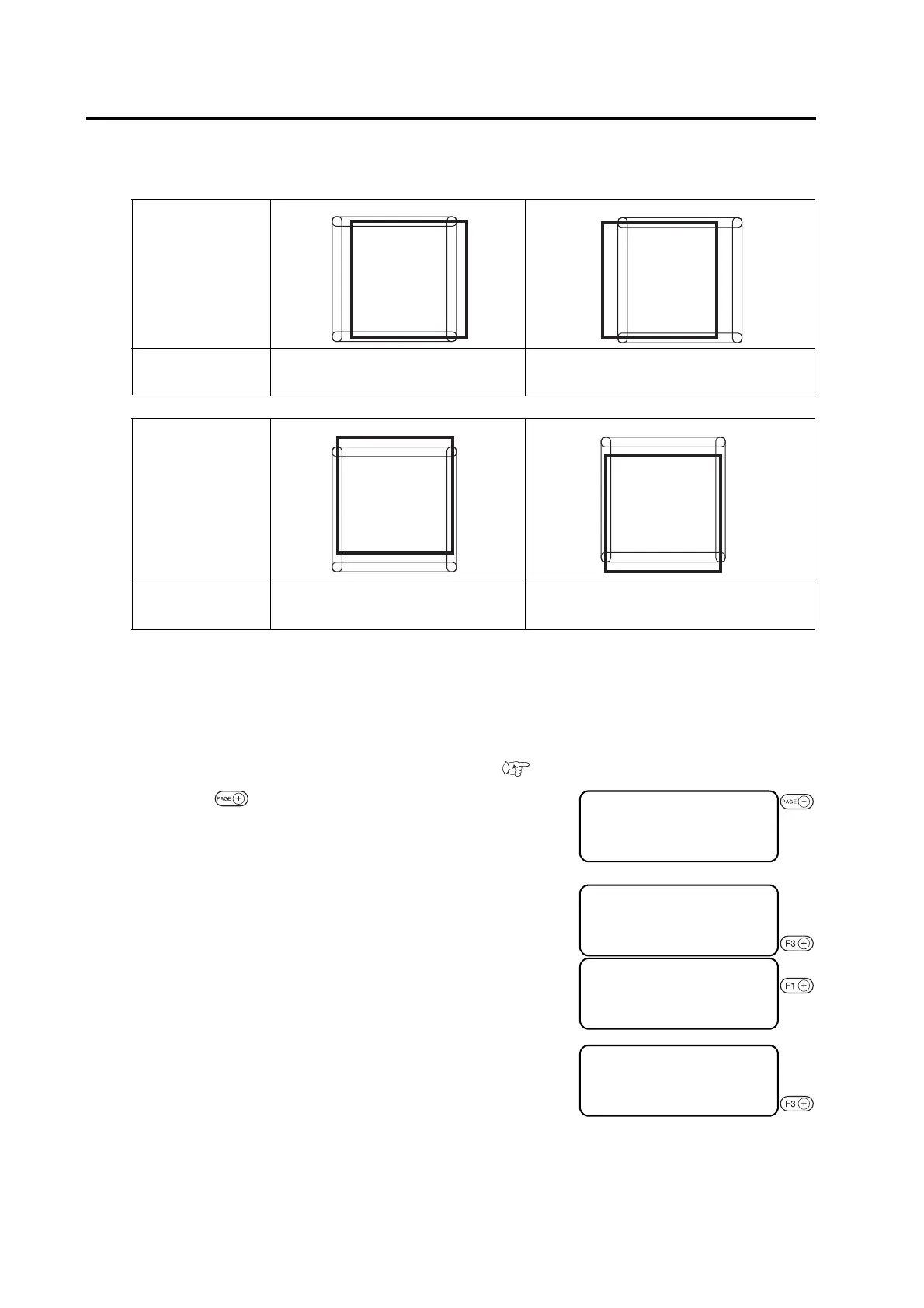

The illustration on the left is for when a roller is set to unit B, when a

tangential cutter is set to the unit C.

5. To check for the eccentricity of the cutter, select the

[TEST PATTERN] to cut patterns A and B.

Sample pattern

How to adjust

If the roller deviates to the right, increase

the X value for the roller.

If the roller deviates to the left, decrease the X

value for the roller.

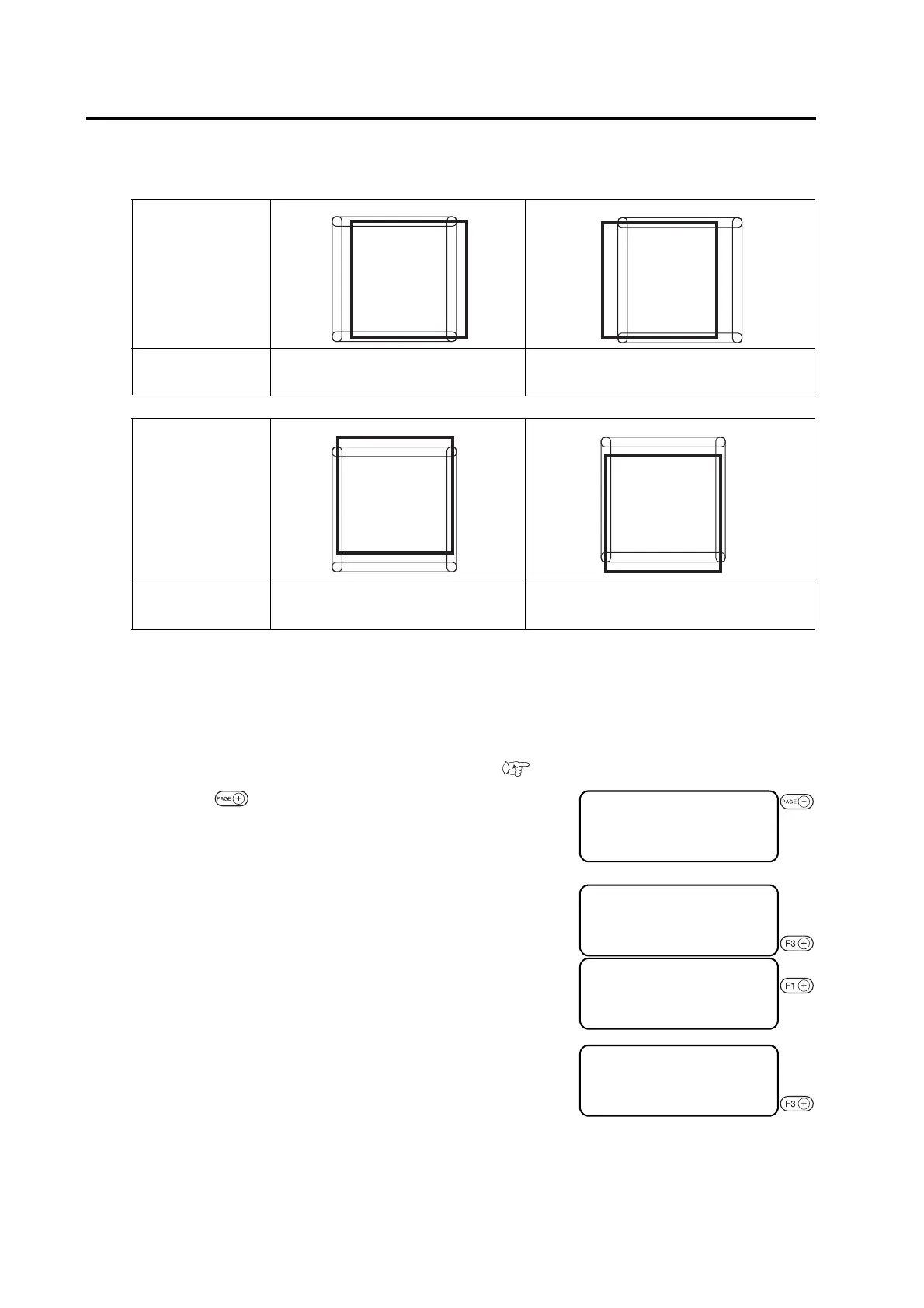

Sample pattern

How to adjust

If the roller deviates upward, increase the

Y value for the roller.

If the roller deviates downward, decrease the Y

value for the roller.

[LOCAL] 1 / 4

TOOL SELECT ――― >

CONDITION ――― >

TEST CUT ――― >

[LOCAL] 4 / 4

CUT AREA ――― >

AXIS ALIGN ――― >

TOOL ADJUST ――― >

< TOOL ADJUST > 1 / 2

B CUTTER ADJUST ――― >

C ROLLER ADJUST ――― >

CIRCLE θ CORP ――― >

< ADJ > SWIVEL 1 / 3

A (LNG) **. **>

B **. **>

TEST PATTERN ――― >

Loading...

Loading...