TOOLS ARE NOT ALIGNED TO EACH OTHER [TOOL SELECT]

3-7

Adjustment of the cutter

The cutter is adjusted in three different ways as described below.

(1) “Adjustment of the eccentricity” to adjust the eccentricity of the blade tip and tools

(2) “Adjustment of θ angle” to adjust the rotating angle of the cutter

(3) “Adjustment of the offset” to eliminate the deviation between the tangential cutter and the pen

Adjustment of the eccentricity

The blade tip or a tool may be off-center when it is replaced. The following indicates an example of the blade tip or

tool that is off-center and how to adjust it.

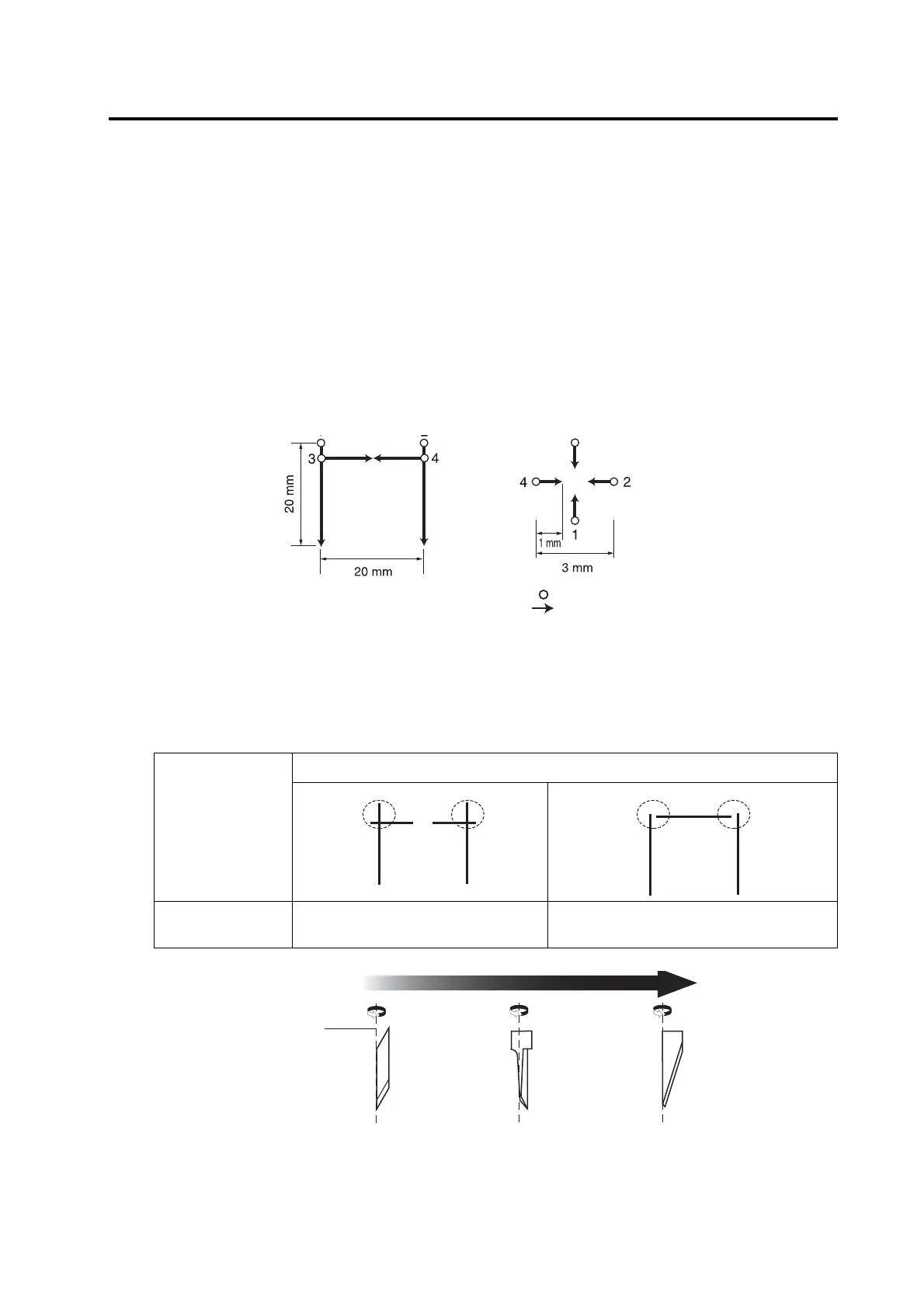

Two different patterns for adjustment are simultaneously cut. Sizes of the patterns and the cutting order are shown

below.

Pattern A Pattern B

How to adjust:

Follow the adjusting procedure given below.

In pattern A, the center position is adjusted by checking and adjusting the relationship between the blade tip and the

center of the cutter according to the target.

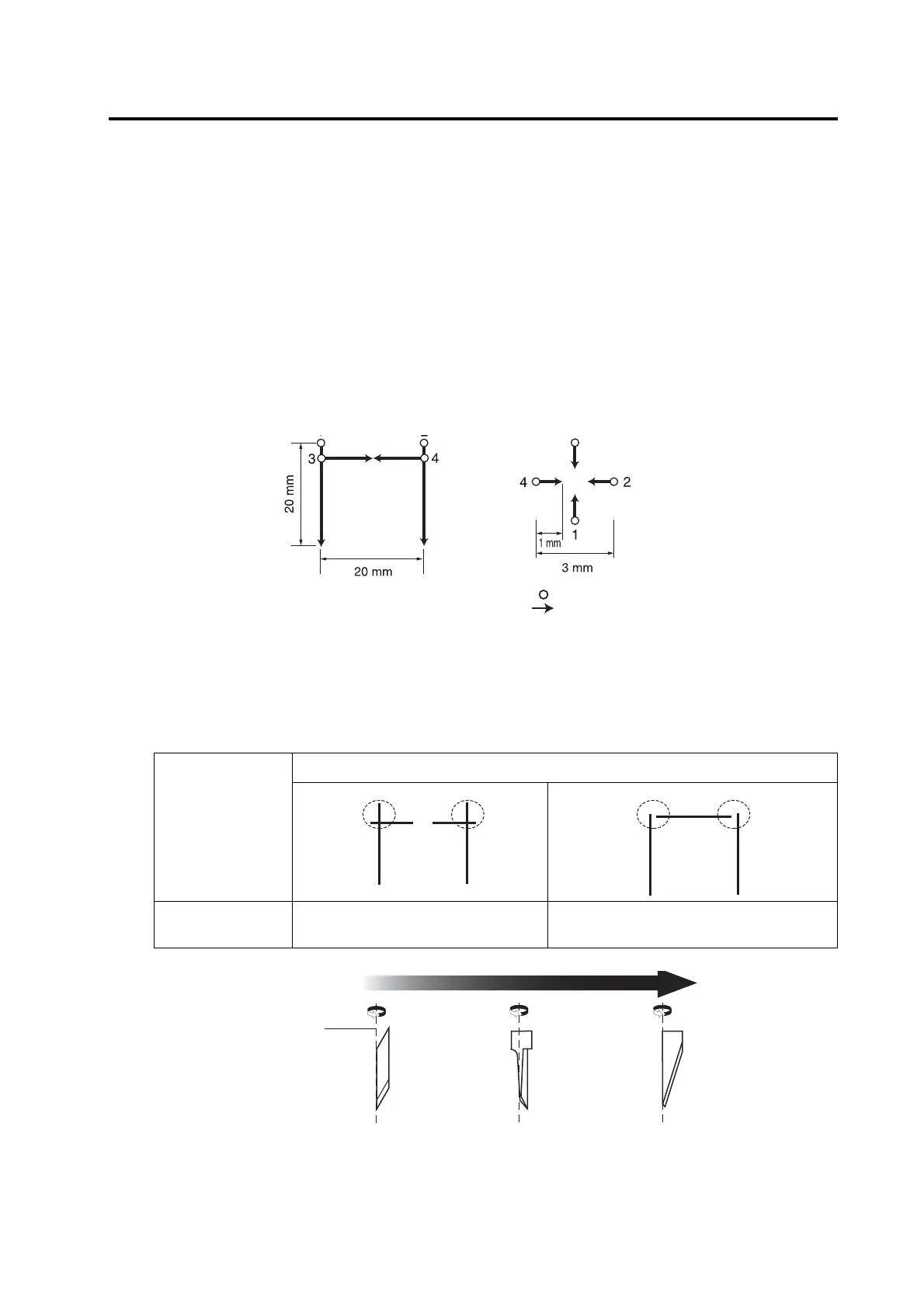

Normally, adjustment is performed so that the blade does not stick out too much and there is no gap. Adjust the back

of the cutter to the center position, as shown in the following figure.

Sample pattern

Pattern A

How to adjust

Reducing value A reduces the amount of

protrusion.

Increasing value A reduces the gap.

:Pointfromwhichcuttingstarts

:Directionofcutting

Placecutterback

atcenter

Incaseofcabideblade30°

Incaseofcabideblade2°

(SPB-0064)

Incaseofcabideblade17°

Loading...

Loading...