2-23

SETTING CUTTING CONDITIONS [CONDITION]

Cutting conditions are set for the tool that has been selected in the [TOOL SELECT].

Setting items

Cutting condition setting items differ with the tools.

• In the case Approximate Type is set to “Arc” on the FineCut plotter settting, excesive pressure

may applied and damage the cutter depend on the media type. When set to “Arc”, be sure to

readjust the cut condition of FineCut or set the [R speed] on the plotter. When [R speed] is set,

[R speed] value is given priority over the FineCut speed setting.

• When using a cutter holder 2N, be sure to set the “VIBRATION” of cut condition to “OFF”.

If “VIBRATION” is set to 1 to 5, cutter holder or this machine may be damaged.

Setting item Description Pen

Tangential

cutter

Crease

roller

Swivel

blade

Speed The speed at which the tool moves.

○○○○

Pressure A pressure that is applied by the tool to a work.

○○○○

Accele The max. acceleration specified for the tool.

Change the acceleration in accordance with the types of

tools and works to be used as well as data sizes.

○○○○

Offset Offset amount of the blade tip of the swivel blade is speci-

fied. Change the offset in accordance with the work thick-

ness and wear of the blade tip.

○

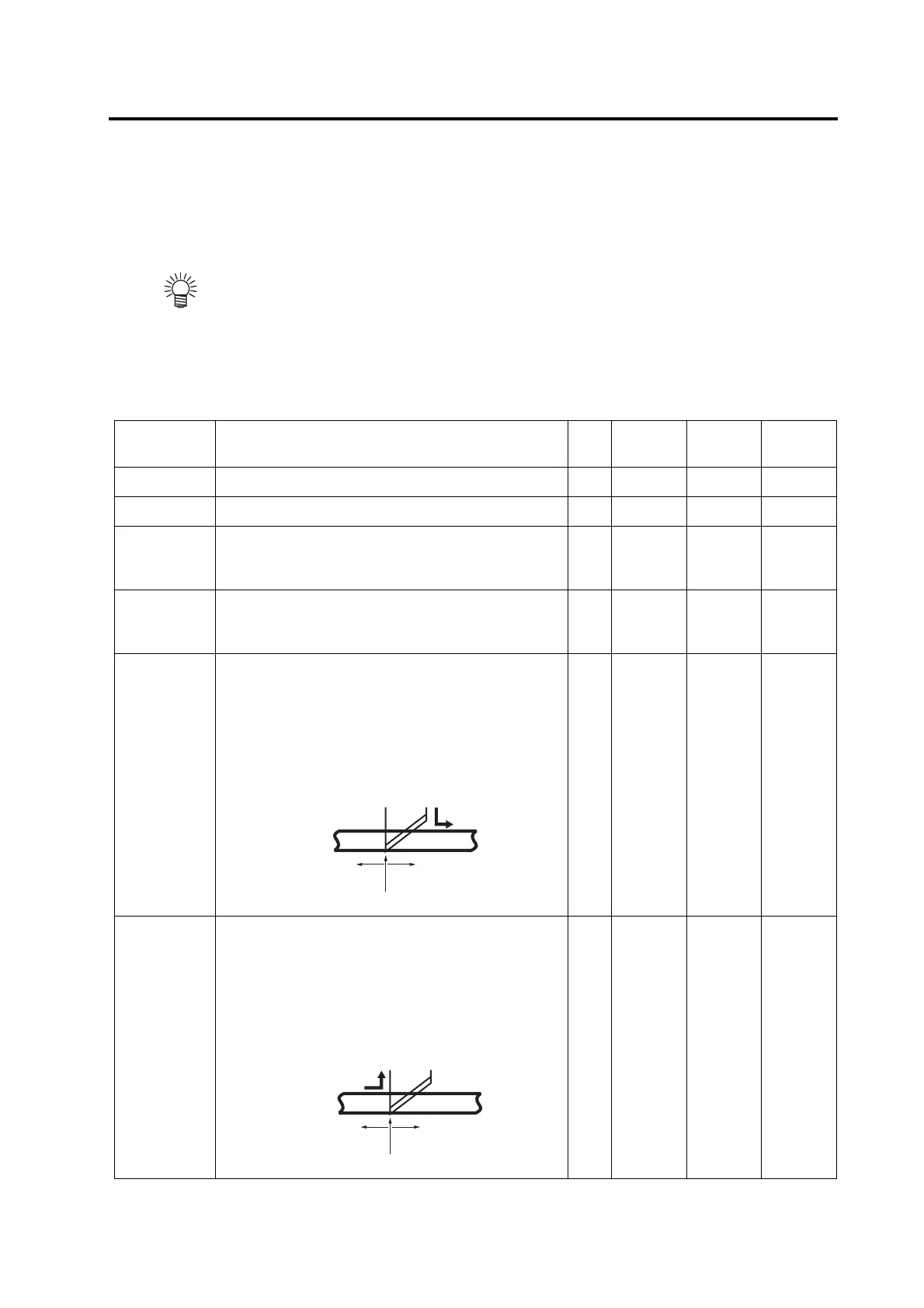

Front offset The amount of correction of the powition from which cut-

ting starts when the tool comes down.

For heavy-weight materials, the amount of correction

should be increased. This will cause the cutter to start cut-

ting from this side of the predetermined start position,

thereby allowing easy cut-out of the work.

Adjust the start position while checking the finished state of

products.

○○

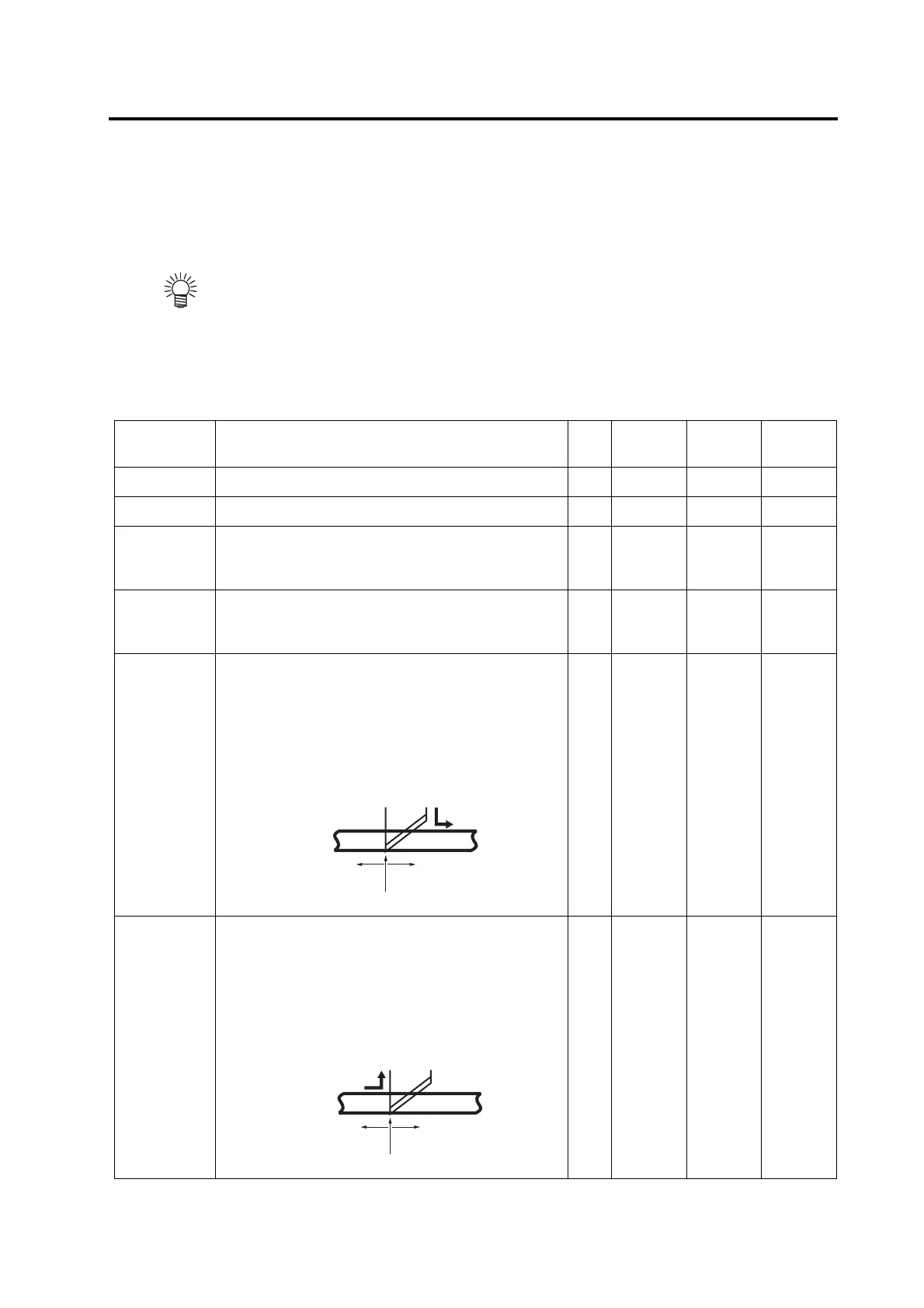

End offset The amount of correction of the position at which cutting

ends when the tool goes up.

For heavy-weight materials, the amount of correction

should be increased. This will cause the cutter to finish cut-

ting at a position that goes beyond the predetermined cut-

ting end position, thereby allowing easy cut-out of the

work. Adjust the start position while checking the finished

state of products.

○○

Work

Increase the

cutting depth

Decrease the

cutting depth

Cutting start position in terms of data

Work

Dcrease the

cutting depth

Increase the

cutting depth

Cutting end position in terms of data

Loading...

Loading...