3-10

Adjustment of the roller

The roller is adjusted in three different ways as described below.

(1) “Adjustment of the eccentricity” to adjust the eccentricity of the tools

(2) “Adjustment of the q angle” to adjust the rotating angle of the roller

(3) “Adjustment of the offset” to eliminate the deviation between the roller and the pen

Adjustment of the eccentricity

The tool may be off-center when it is replaced. The following indicates an example of the tool that is off-cen-

ter and how to adjust it.

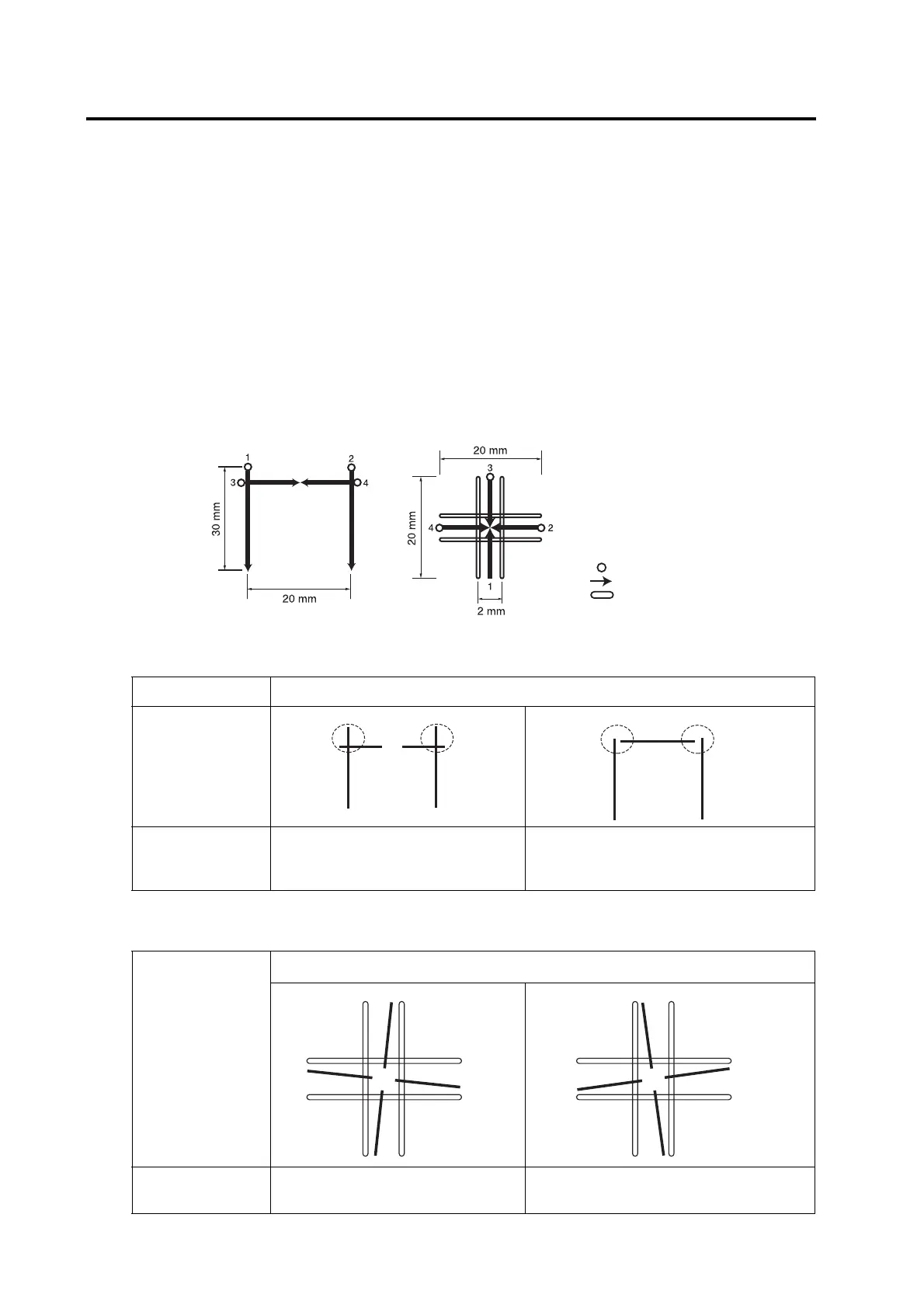

Two different patterns are used for adjustment. Pattern A is used for the adjustment of marking.

Pattern B is used for the adjustment of plotting and marking. Sizes of the patterns and the cutting order are

shown below.

For pattern A, the marking roller, being different from the tangential cutter, goes beyond the cutting area even

it is not off-center.

Pattern A Pattern B

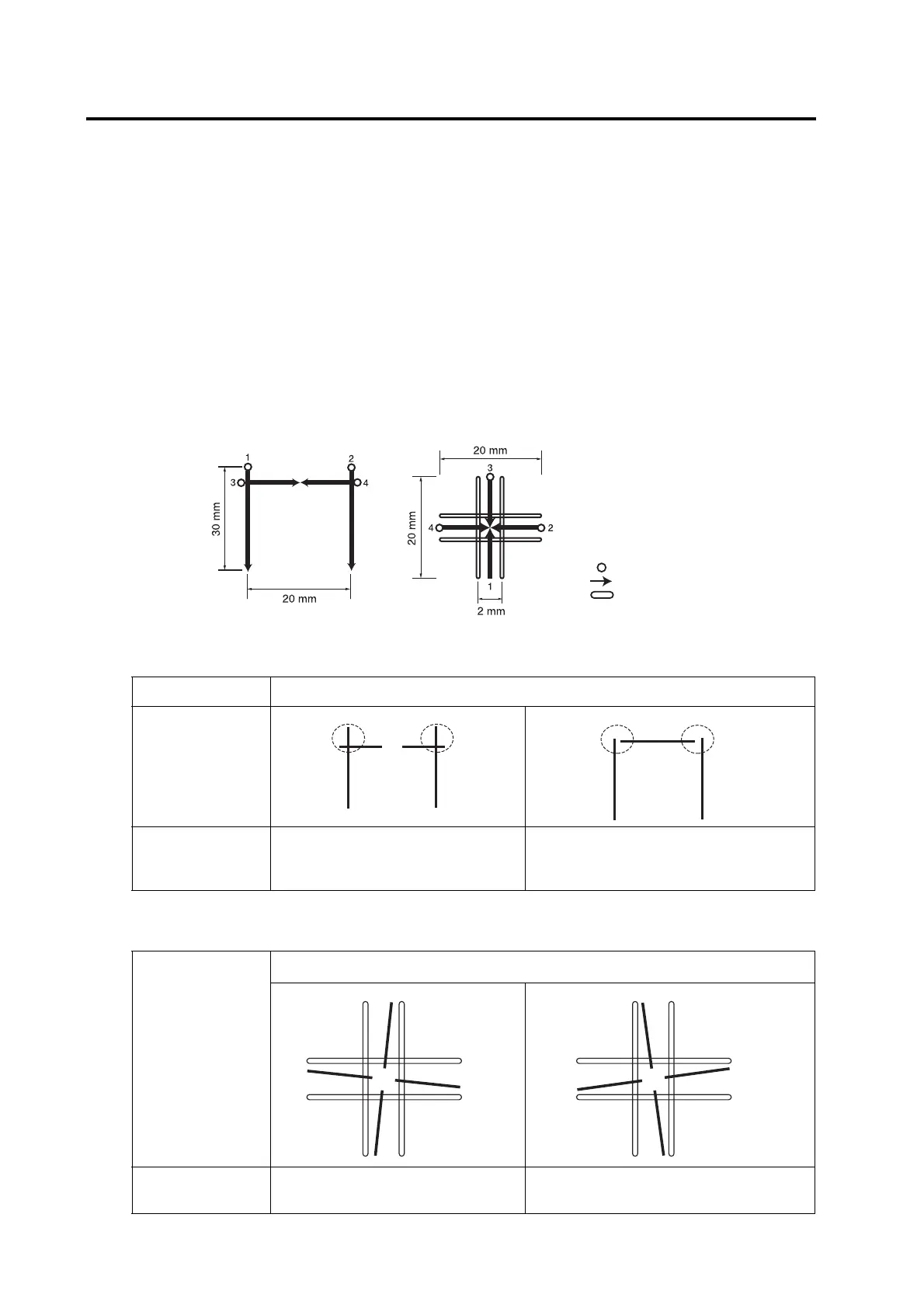

How to adjust:

Pattern A has to be adjusted to correct the problem where the blade tip is out of the center of the roller holder.

In pattern B, the tool is installed with tilted. Pattern B has to be adjusted so that horizontal lines and vertical lines are

arranged in a straight line respectively along X- and Y-axes.

Pattern A

Sample pattern

How to adjust

Input a negative value as “A” that corre-

sponds to the length of the line which goes

beyond the vertical line.

Input a positive value as “A” that corresponds to

the length to be plotted to reach the vertical line.

Sample pattern

Pattern 1 (Pattern 2)

How to adjust

Input a positive value as “B” that corresponds

to a half of the distance between the two lines.

Input a negative value as “B” that corresponds to

a half of the distance between the two lines.

:Pointfromwhichcreasingstarts

:Directionofcreasing

:Pen

Loading...

Loading...