1

2

3

4

5

6

7

8

© 2011 MIMAKI ENGINEERING CO.,LTD. 1.1.3 R.2.0 P.1

Maintenance Manual > Operating Principle > Basic Operation > Work Area Sensor

Model UJF-3042/FX Issued 2010.08.27 Revised 2011.09.30 F/W ver 1.80 / 1.00 Remark

2.0

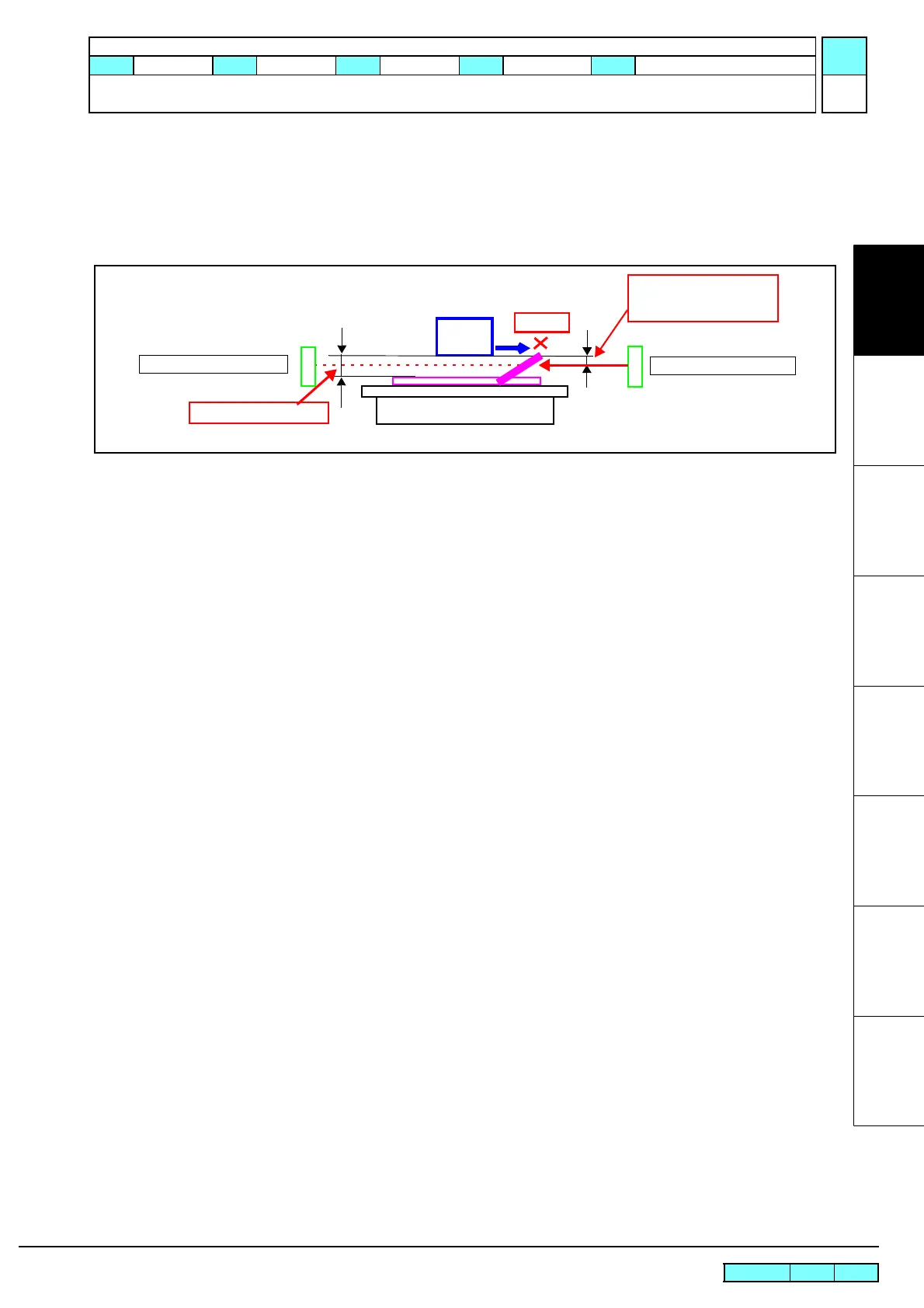

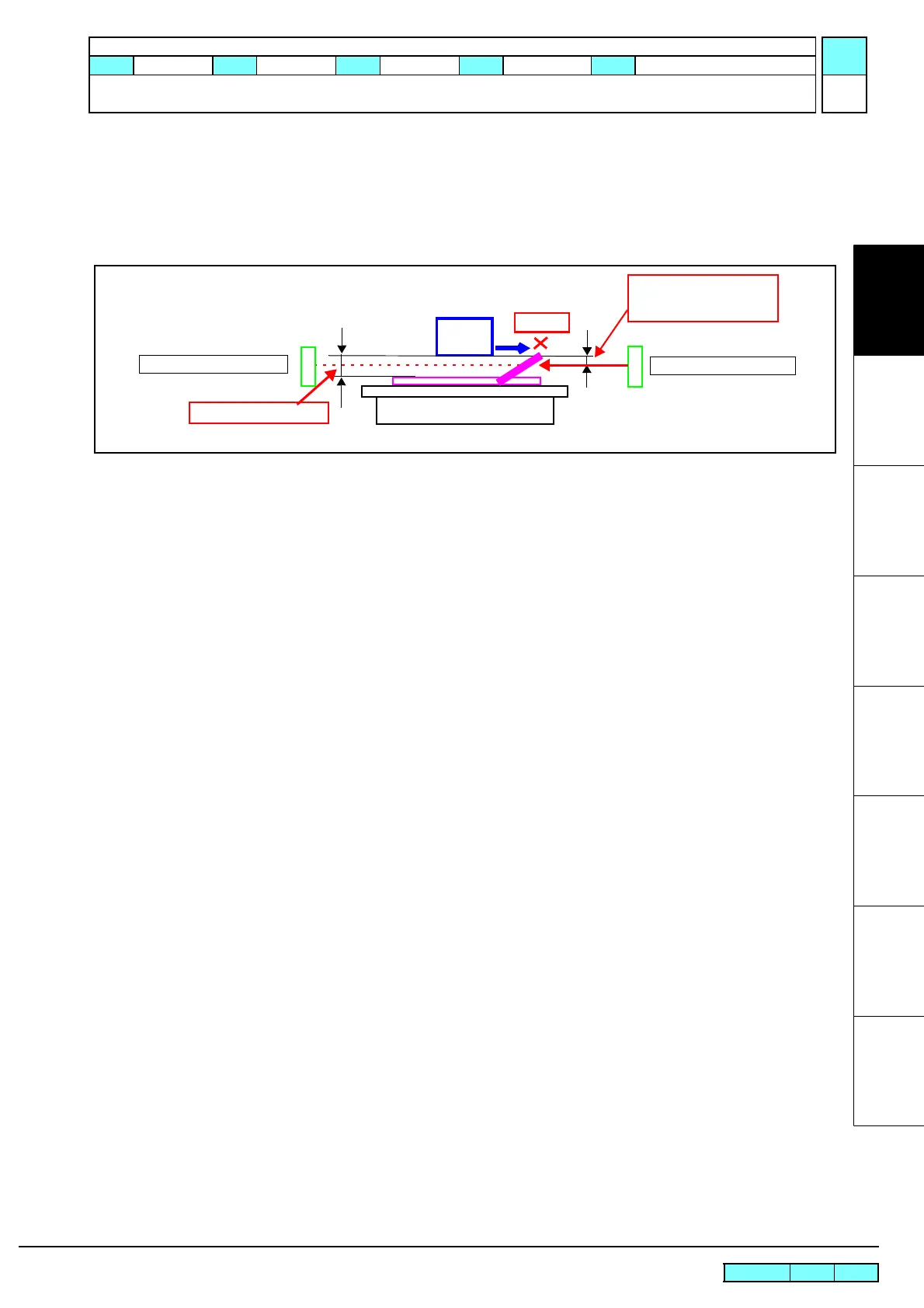

1.1.3 Work Area Sensor

Outline

This sensor is set to prevent the head from being damaged. It detects the work coming out or warpage etc. on the table

to stop the operation before the head hits that part.

Figure of constitution

Operating Principle

1 The light axis of the obstacle sensor is set below 0.5mm from the bottom surface of the nozzle.

2 When LED light of the sensor (visible light) is shaded by the obstacle, the operation is terminated.

3 Before the printing operation, checks whether there is no obstacle by moving the Y-Bar back and forth with the

head being stored in the station.

Table

Head

Basic head gap: 1.5mm

Light axis position

Below 0.5mm from the bottom

surface of the head

Sensor for floodlighting

Sensor for receiving light

STOP!

Loading...

Loading...