2 Basic repair procedures Chapter E: Basic repair procedures

166 Planmeca PlanMill 40 Technical manual

5. Disconnect servo motor encoder cable from the interconnect board.

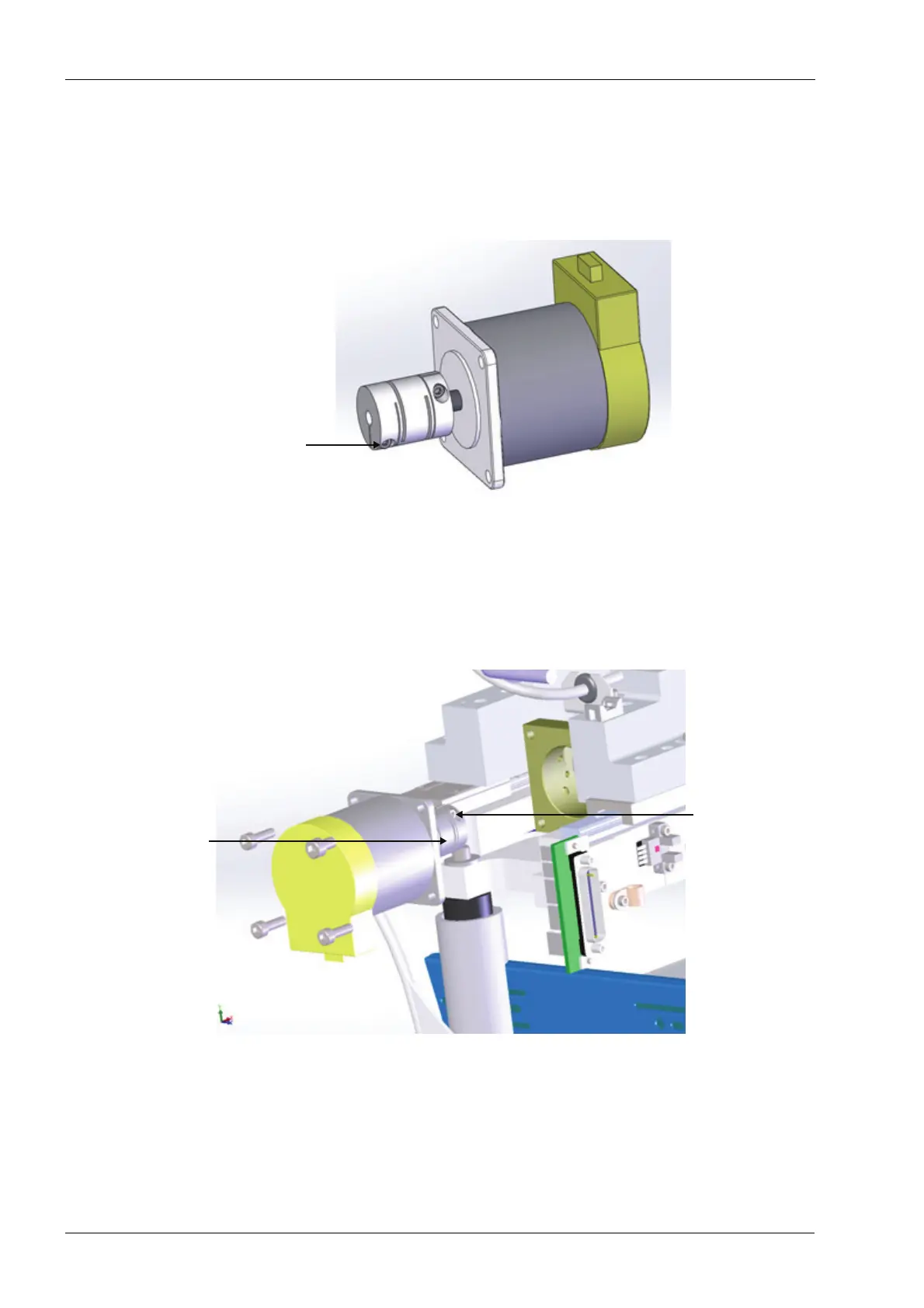

6. Loosen but do not remove the clamp screw for the ball screw end of the coupling (with

the power off and cables disconnected the coupling may be slightly rotated manually

using a pencil eraser in order to access the clamp screw). Refer to the following

figure.

Figure 177: Servo motor with coupling

Attempting to remove motor with coupling still attached to the ball screw will break

or damage the coupling.

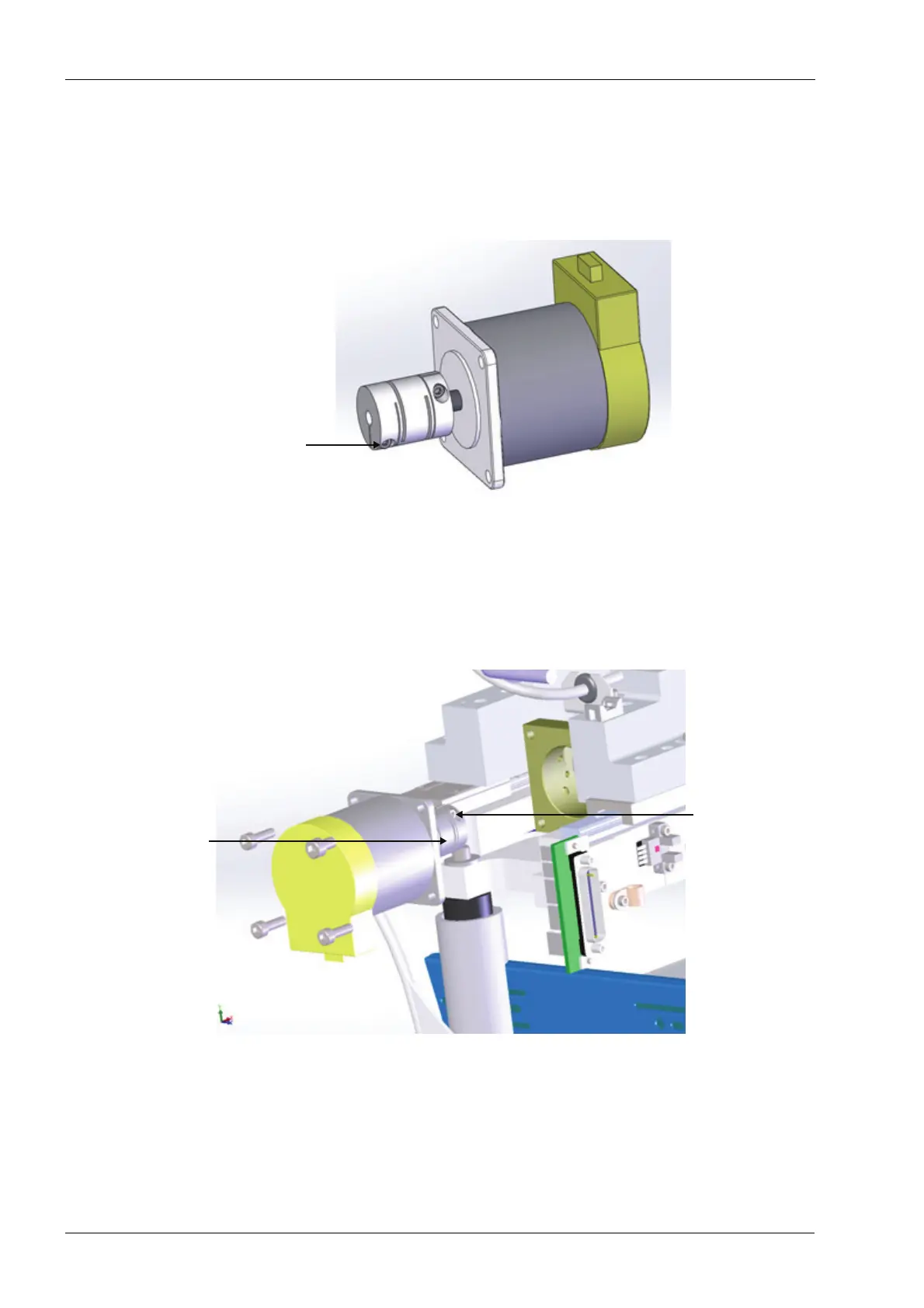

7. Use a 4 mm Allen key and remove (4) screws securing the servo motor to the motor

mount and carefully slide the motor out of chassis. Refer to the following figure.

Figure 178: Servo motor with coupling

Install

Installation of a new servo motor requires a careful alignment procedure, described

in the following steps. Failure to follow the alignment procedure can cause prema-

ture failure of mill components.

Clamp screw for

ballscrew

end of coupling

Servo motor

coupling

Loosen clamp

screw on the

ballscrew

end of coupling

Loading...

Loading...