7 Mechanical design Chapter A: General and technical data

16 Planmeca PlanMill 40 Technical manual

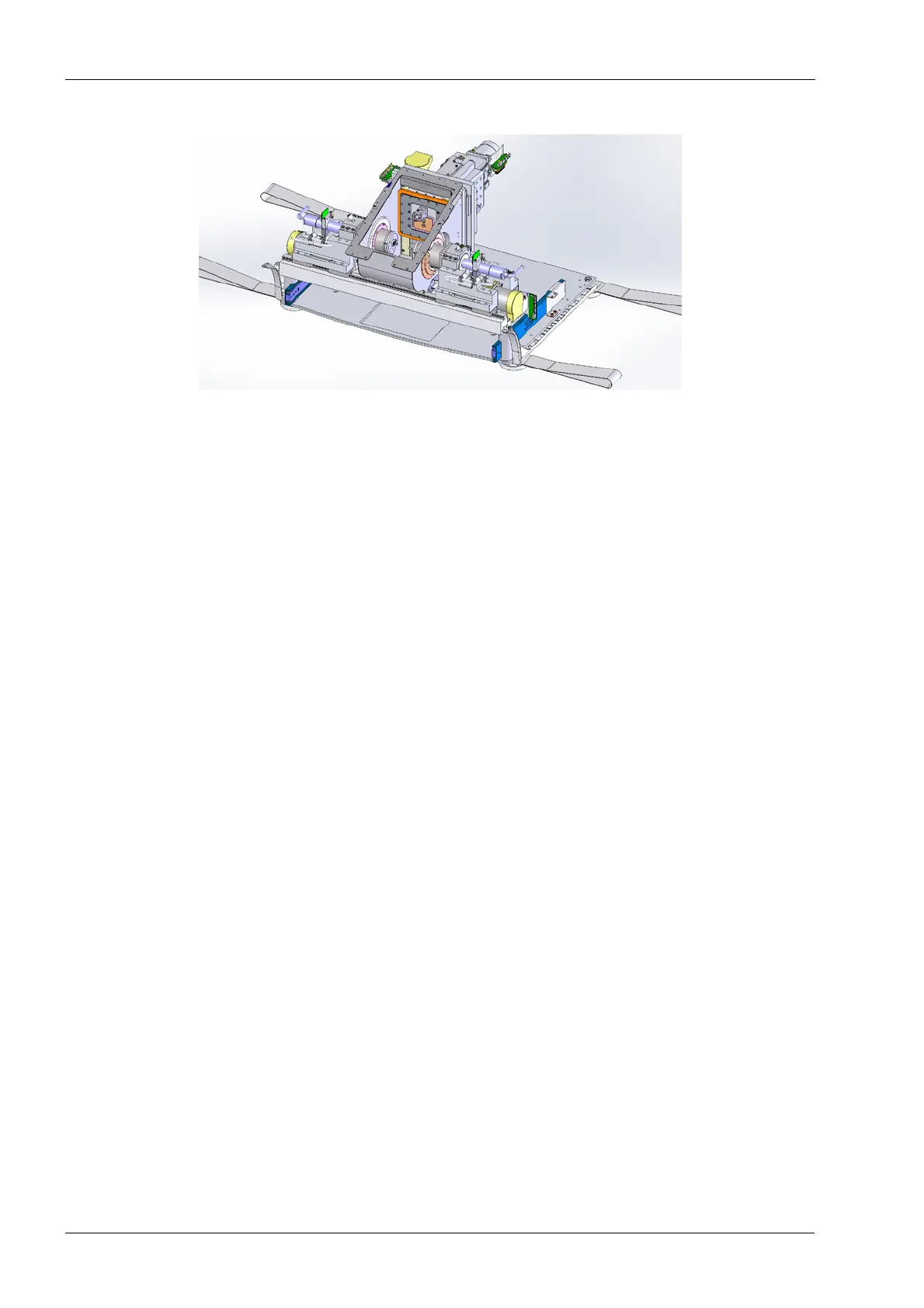

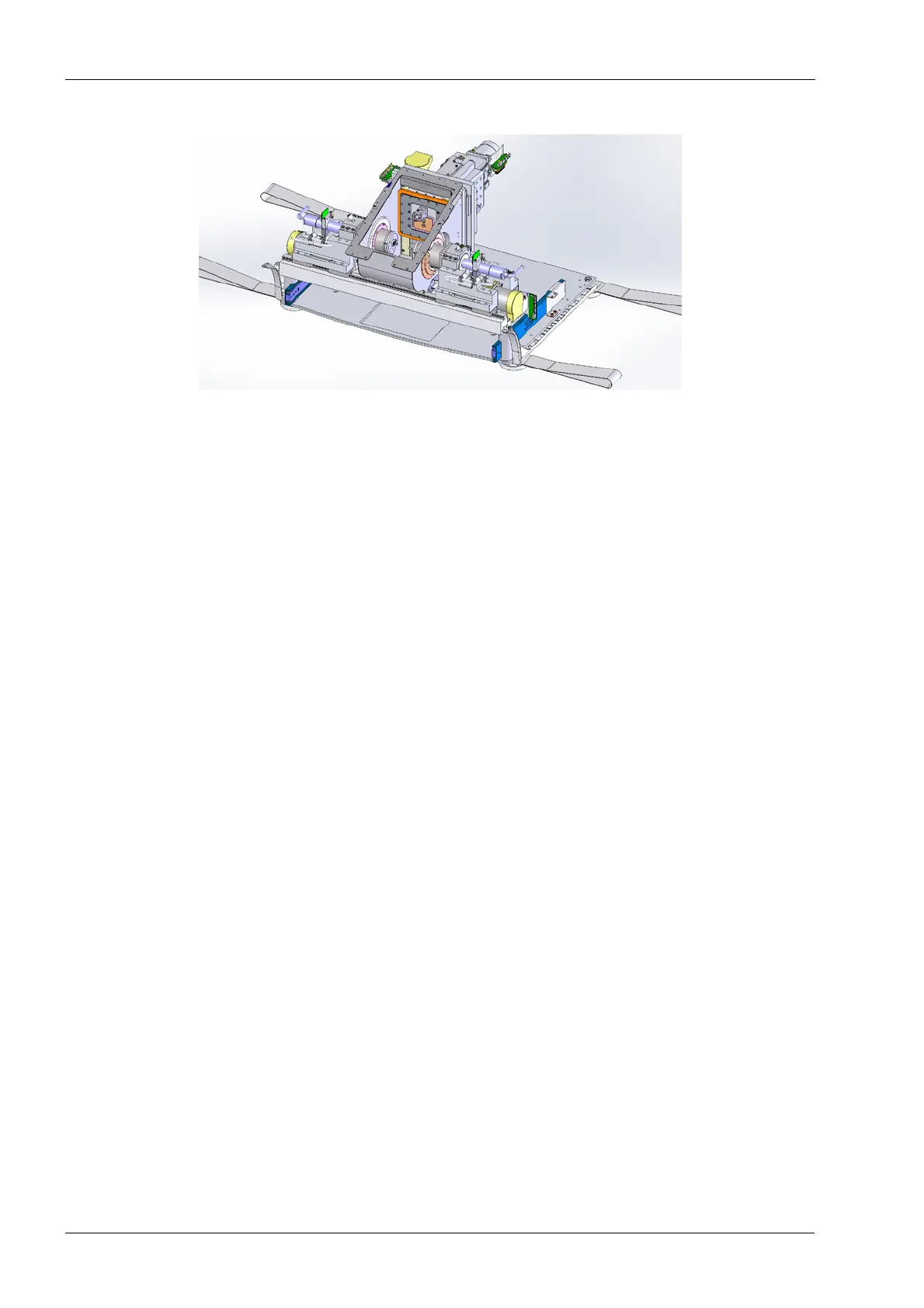

Figure 1: Motion base assembly

7.2 Electronics box

The electronics box is located in the right rear of the machine and consists of an upper and

lower section. The lower section contains the A/C input power conditioning components

and supports A/C, Ethernet, and USB cabling connections. Additionally, there is a

transformer and rectifier circuit to provide voltage for driving the servo motors and

spindles. The upper box mounts atop the lower and provides three dedicated slots to

insert the computer module (CPU module), amplifier module (Amp module), and power

supply module. Each module plugs into the backplane board. This board provides power

and all input and output signals required to operate each module, thus eliminating any

individual cabling connections to the modules.

The opposite side of the backplane board supports cable connector receptacles used to

connect various components via cables to the electronics box. These connector

receptacles are made available through precisely aligned openings in the rear of the box.

The net result of this design is that the cabling connections are made at assembly, and

they do not need to be disconnected if one or more of the modules require servicing. This

greatly increases the serviceability and the robustness of the design. Additionally, the

upper box contains a cooling exhaust fan positioned to take advantage of the natural heat

transfer and adequately cool all electronic components located inside the electronics box

assembly.

The computer stack module incorporates several computer boards stacked upon one

another using the PC104 interface bus. Included in this stack are the single board

computer (SBC), motion controller board, DSP spindle controller/interface board, and

computer hard drive. The SBC is the host computer that handles the windows operating

system; it runs the PlanMill 40 application in addition to handling all networking operations.

The motion controller board is DSP-based and handles the real time control of the four

servo motors. It is under the direct control of the SBC via the PlanMill 40 application. The

DSP spindle controller/interface board provides direct control of the spindle motors and

low level monitoring of all sensors. FPGA coded chips and Firmware are both used to

monitor and control these components. This board is also under direct control of the SBC

via the PlanMill 40 application. Additionally, this board handles all the cabling connections

from the SBC, hard drive, and motion controller board and it connects the signals to the

backplane board.

The amplifier module contains the four servo amplifiers which are mounted to a PC board.

This board plugs directly into the backplane. The purpose of the servo amplifier is to take

the low voltage TTL signals from the motion controller board and amplify them to drive the

servo motors which operate at a nominal 42 Vdc. Because the amplifier components

generate heat, there is also a heat sink plate that is one side

of the upper electronics box.

Loading...

Loading...