7 Mechanical design Chapter A: General and technical data

18 Planmeca PlanMill 40 Technical manual

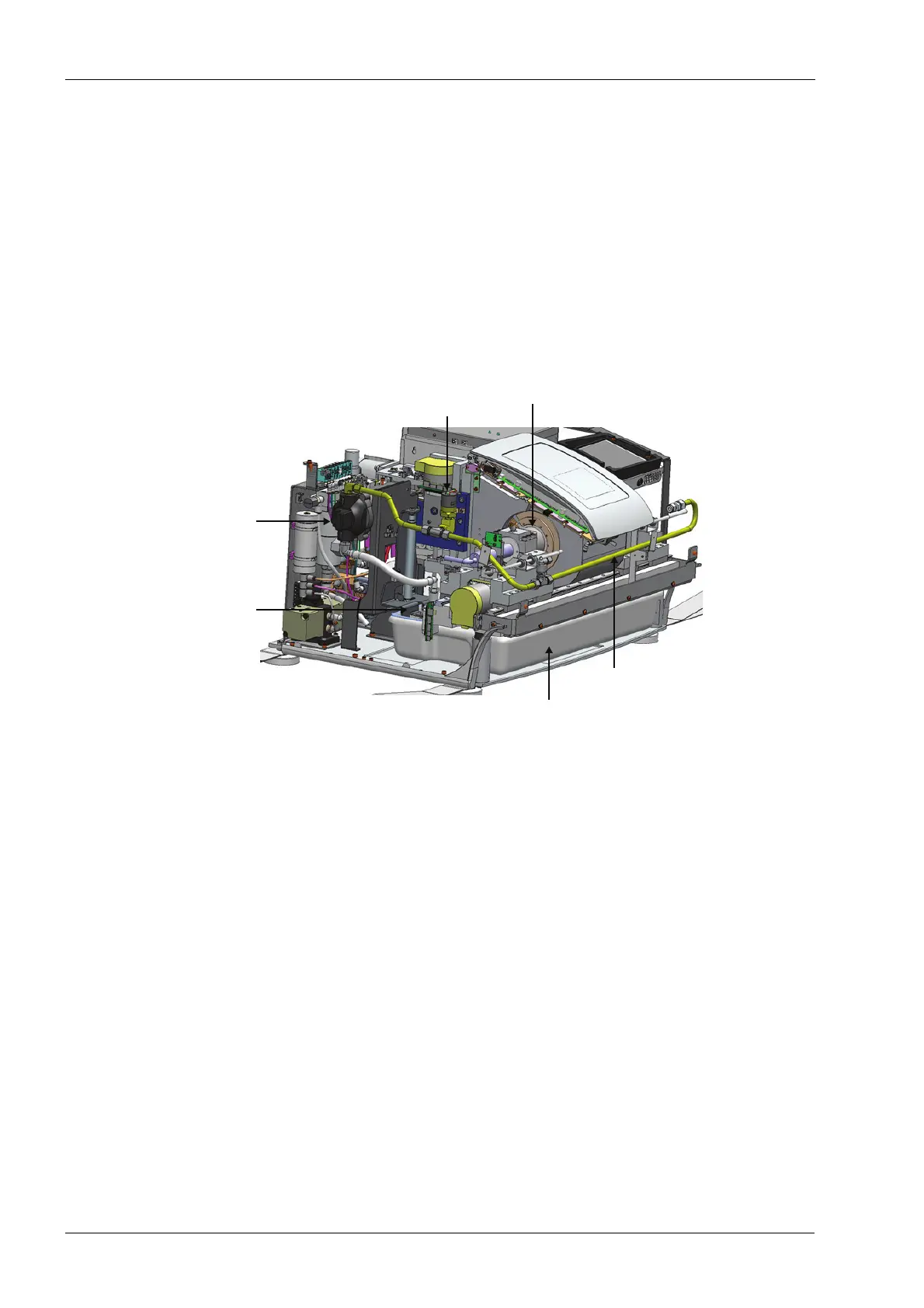

The plastic fluid tank is positioned in a drawer below the grind chamber. The tank is sized

to allow extended operation of the milling unit without servicing, typically 3 hours. Tank ID

sensors detect tank presets. Additionally there is a sensor providing verification that the

drawer is either open or closed. This drawer is accessible to the operator for servicing by

entering the proper maintenance routine. Upon entering this routine, the drawer is

unlocked and the pump suction line and fluid level sensors are raised out of the tank, thus

freeing the drawer and tank to be opened for service. The high and low water level

sensors provide coolant level indications to the operator.

The pump assembly is located in the left rear of the mill and utilizes a self-priming

diaphragm pump. This pump is sized to conservatively deliver adequate coolant pressure

and flow for the grinding process. Mounted on the discharge side of the pump is a

pressure switch that provides a feedback signal indicating adequate pressure for milling.

Figure 4: Coolant circulation system

7.4 Pneumatics system

Several components on the milling unit require pressurized air to operate. The control and

use of pressurized air is known as the pneumatics system. The source of the pressurized

air is external to the milling unit and is provided via a supply line connected to the rear of

the machine. The quality of the provided air should fulfill the air purity requirements (refer

to section 5 "Technical specifications" on page 12). Additionally, the pressure and flow

should be adequate to provide a minimum of 3.5 bar (50 psig) at 60 l/min (0.06 m

3

/min, 2

CFM).

Major components of the pneumatics system include the separator, filter and regulator

assembly, solenoid control valves, and pneumatic components. The incoming air is

passed through an on-board conditioning system to provide a minimal amount of

protection from a poor quality air source. These components are specifically: a water

separator unit (to remove liquid water droplets from the incoming air), a filter unit, a micro

filter unit, and a regulator assembly. The two filter units ensure all particulates beyond a

specific size are removed from the supply air, and the regulator reduces the incoming

pressure to 3.5 bar (50 psi) for on board use.

Pump

assembly

Coolant

pressure

switch

Spindle housing

& nozzle caps

Float

switches

& suction

assembly

Fluid tank

Tubing

Loading...

Loading...