Chapter A: General and technical data 7 Mechanical design

Technical manual Planmeca PlanMill 40 19

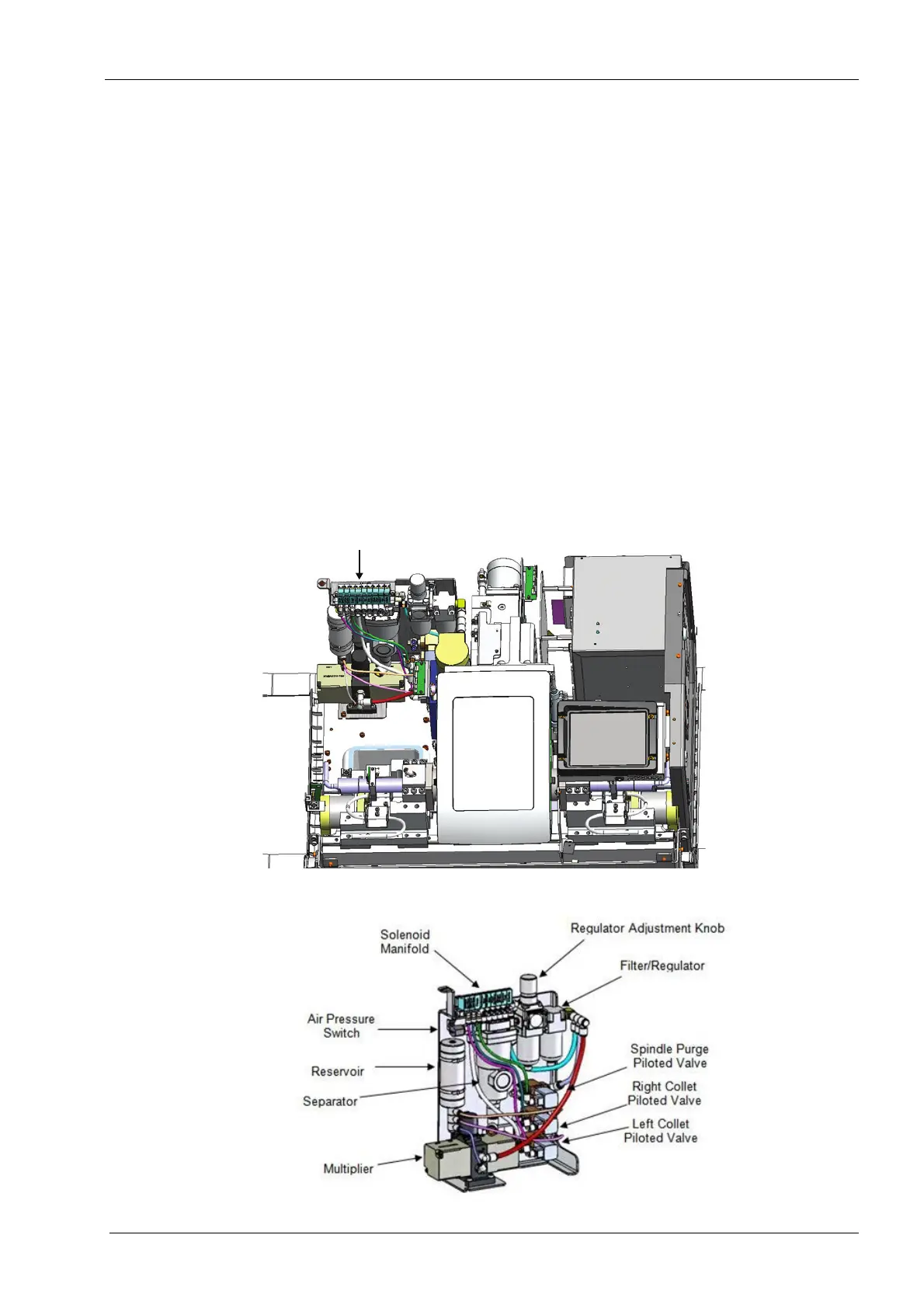

Control of the air is handled by the bank of electrically driven solenoid valves mounted on

a common manifold. Each solenoid is digitally controlled by the computer and can provide

pressurised air on demand to the pneumatic component, which is typically an air cylinder

that is connected by silicon tubing supply line. Each air cylinder’s rate of operation can be

fine-tuned by using manually adjustable inline flow control valves that can control the

volumetric flow to and/or from the cylinder, thus controlling the rate of extension and

retraction. Opening and closing the spindle collets require significantly higher pressure

than other components, specifically 6.9 bar (100 psi). This higher pressure is obtained by

using a component called a pressure multiplier. The pressure multiplier uses the 3.5 bar

(50 psig) supply air to drive itself and compress an additional stream to 6.9 bar (100 psig).

This higher pressure air flow is controlled by two separate piloted control valves. The

piloted control valve is similar to an electrically driven solenoid valve, except the open/

close signal is provided by supplying pressurized air to the control port on the valve. This

control air is supplied by one of the manifold-mounted solenoid valves. The net result is

that all pneumatic operations are controlled via an electric solenoid valve mounted on the

manifold. In the case of the collets, these valves control the piloted valves which control

the high pressure air used to actuate the collets on the spindles. Additionally, a third

piloted valve is used to provide the purge air to the spindle and spindle motor assembly.

This piloted valve is also controlled by a manifold solenoid valve. The piloted valve is used

in this case to provide the 60 l/min (0.06 m

3

/min, 2 CFM) flow rate not capable by the

manifold valve alone.

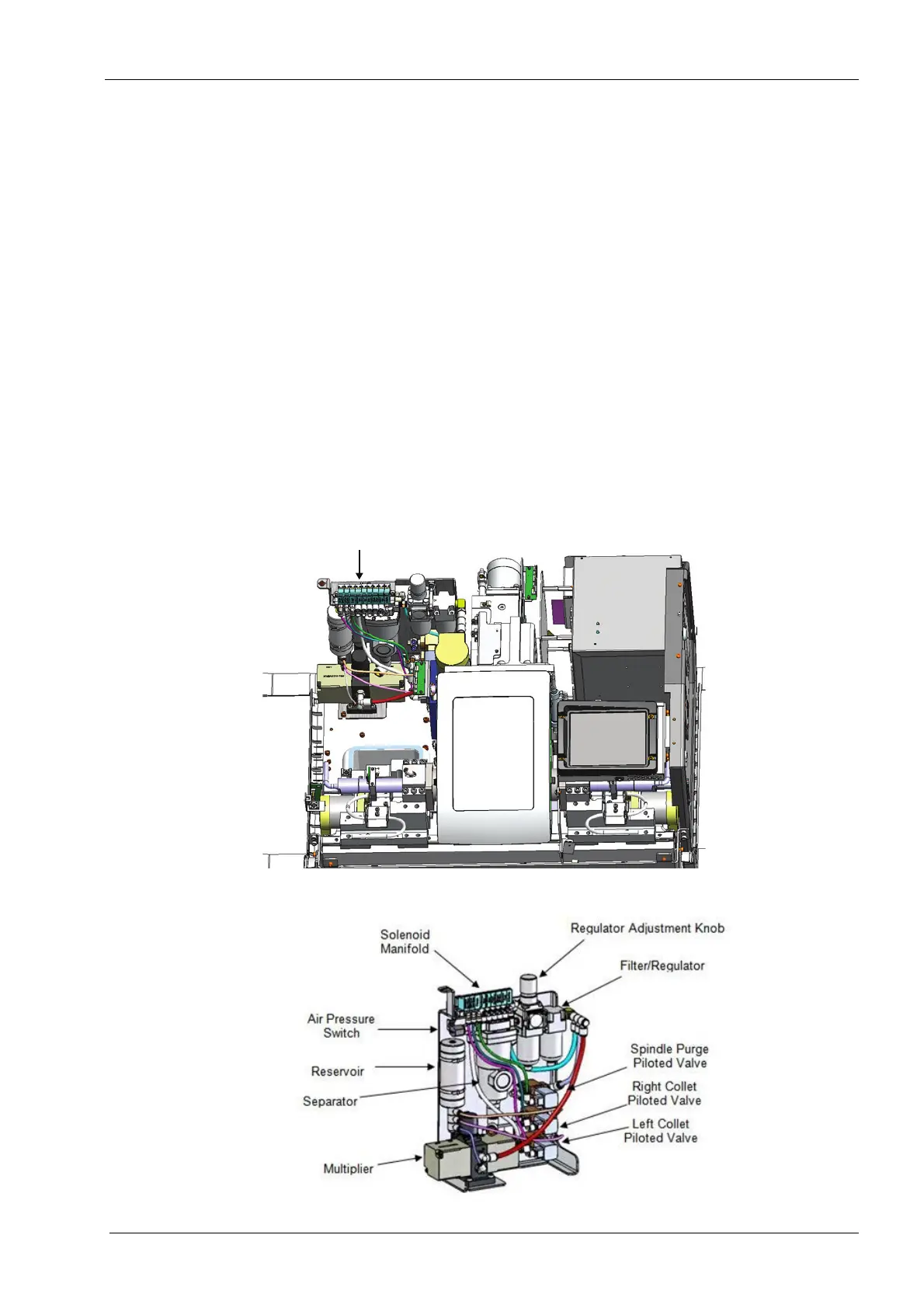

Figure 5: Pneumatic system

Figure 6: Pneumatic assembly

Loading...

Loading...