2 Maintenance procedures Chapter B: Preventive maintenance

26 Planmeca PlanMill 40 Technical manual

2 Maintenance procedures

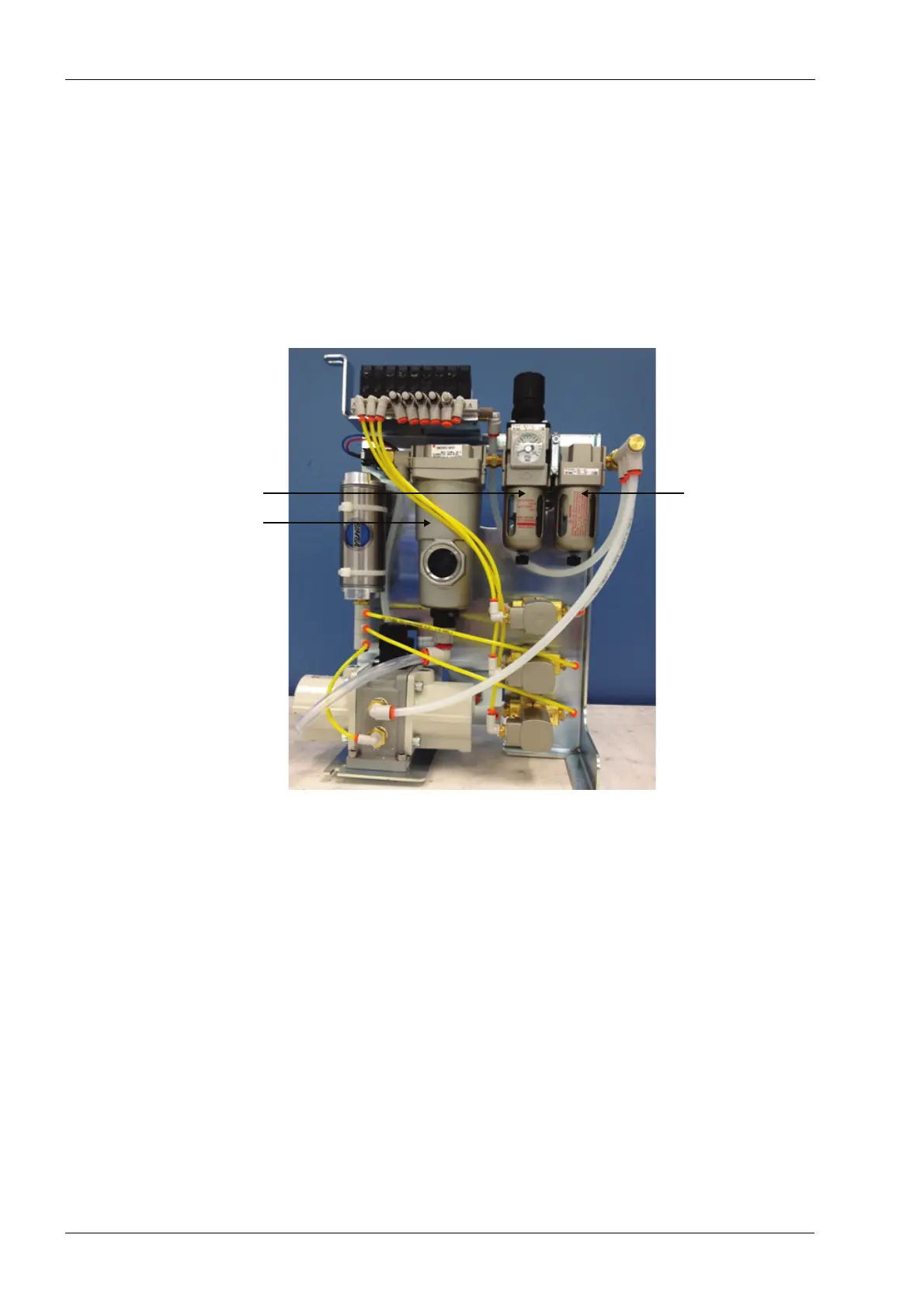

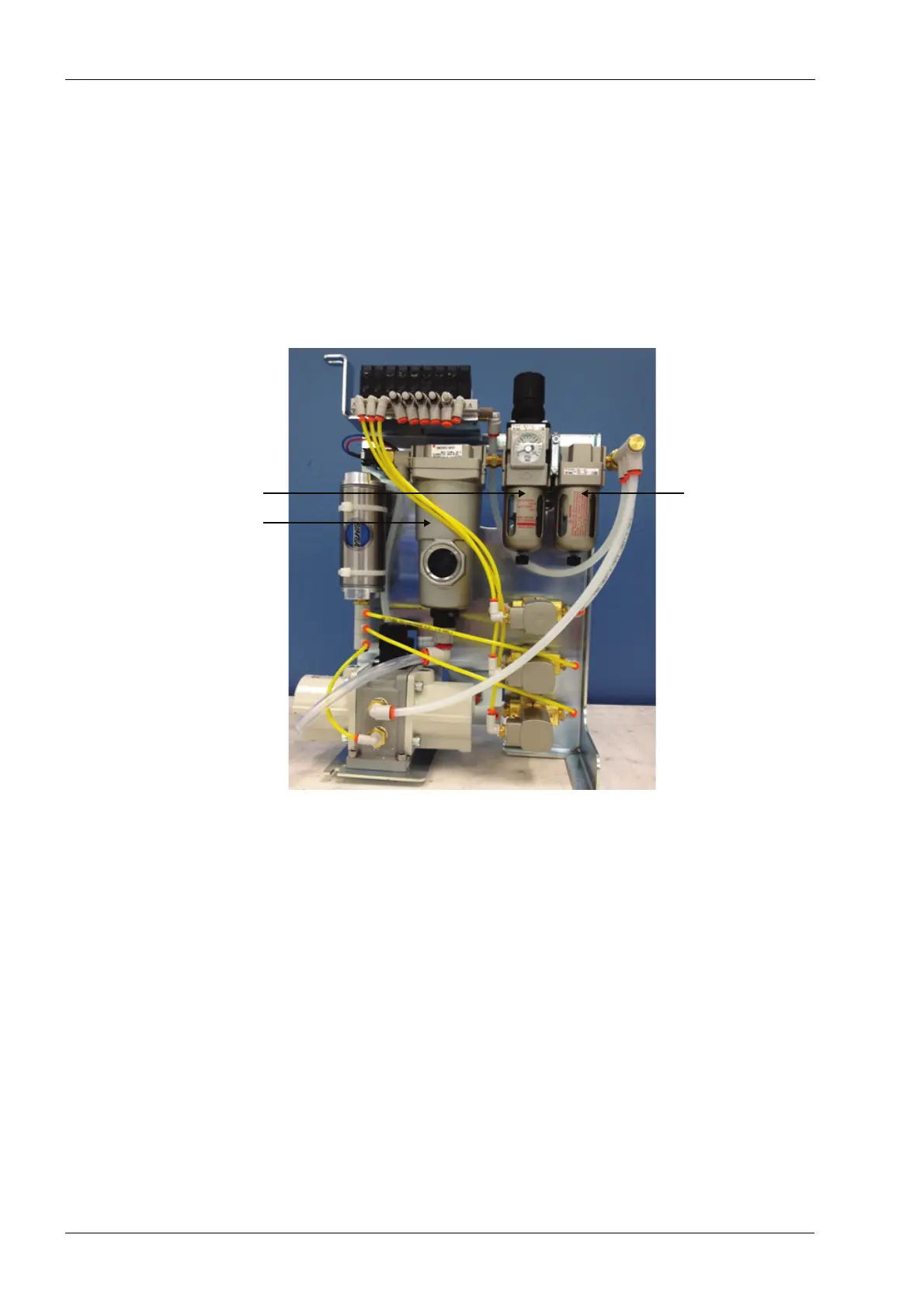

2.1 Inspecting pneumatic filter bowls for moisture

The mill pneumatics assembly includes a water trap with a sight glass, an air filter with a

bowl and a coalescing oil filter with a bowl. These three items are inspected during each

PM to verify they are dry. Significant fluid in the sight glass or bowls indicates excessive

moisture in the compressed air supply to the PlanMill 40.

Figure 12: Pneumatic assembly

1. Disconnect the compressed air supply from the PlanMill 40.

2. Remove the PlanMill 40 top cover and left side cover, see instructions in section 2.1

"Mill covers" on page 94.

3. Visually inspect the water trap, the air filter bowl and coalescing oil filter bowl for

moisture.

4. Droplets of moisture on the sight glass of the Water Trap are normal. The Water Trap

drains automatically via a drain tube if fluid reaches the top of the sight glass. The

drain tube is routed to a mill drawer compartment that contains a sponge. Significant

water on the sponge indicates the presence of excessive moisture from the

compressed air source, which should be corrected immediately.

5. Droplets of moisture, oil and other impurities on the bowls of the air filter or coalescing

oil filter are rare and in some cases acceptable. All fluids, impurities etc. in the filter

bowls should be drained and the purity of the incoming pressurized air should be

checked and corrected.

6. If fluids or impurities are present in the air filter or coalescing oil filter bowls place a rag

or sponge under the bowls to absorb the residues. A manual knob on the bottom of

each of the bowls is loosened by rotating it anticlockwise until the fluid drains out.

Water trap

with auto

drain

Air filter

Coalescing

oil filter

Loading...

Loading...