2 Basic repair procedures Chapter E: Basic repair procedures

158 Planmeca PlanMill 40 Technical manual

• Depress the button on the open tool changer solenoid to energize the air cylinder

opened hold the button down.

• Depress the button on the close tool changer solenoid and release the other button.

Example 3

If the tool changer is in between:

• Manually close the tool changer and follow procedure above.

10. Once proper operation is verified on all operations, reinstall rear, left side panel and

top covers, see section 2.1 "Mill covers" on page 94.

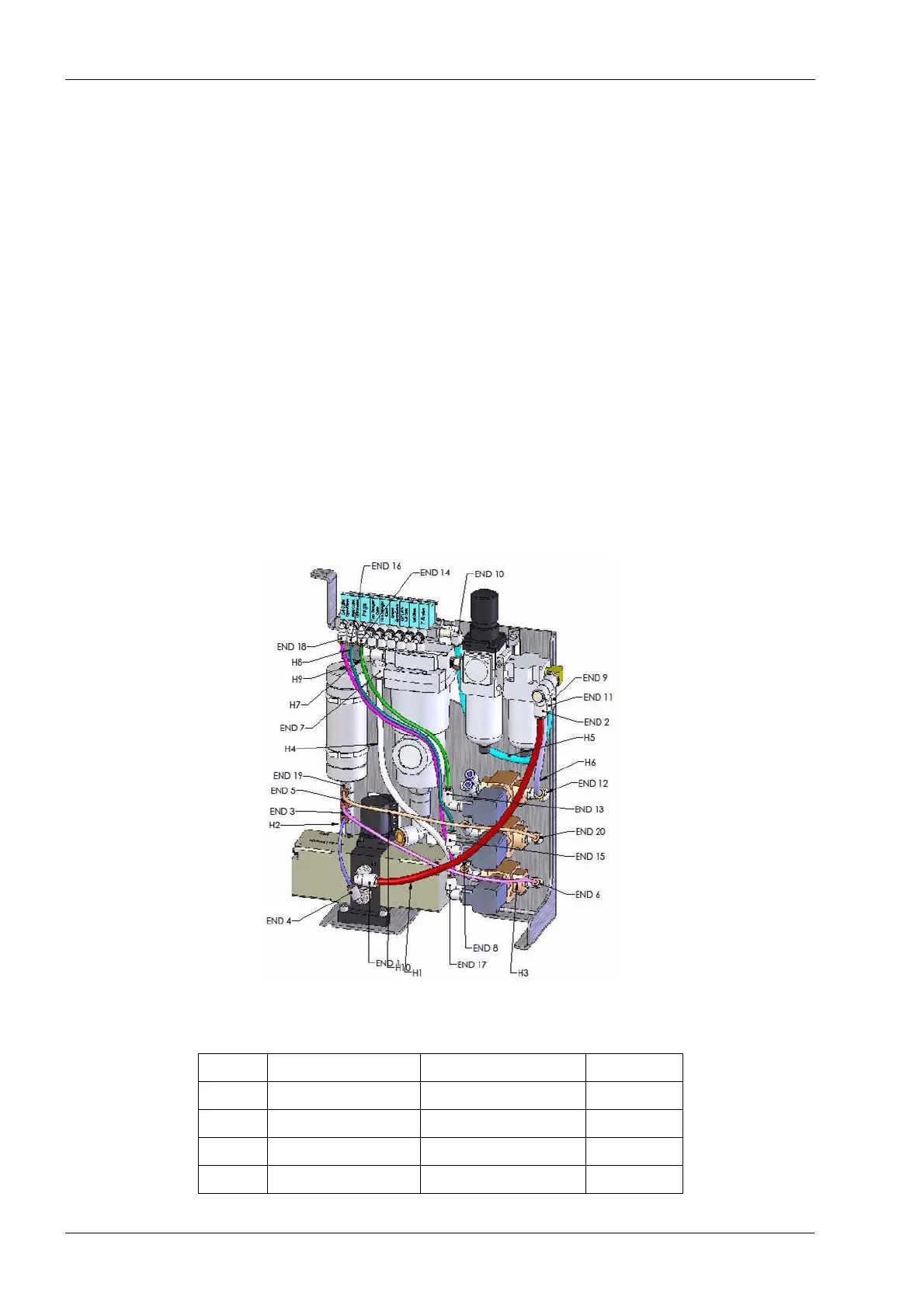

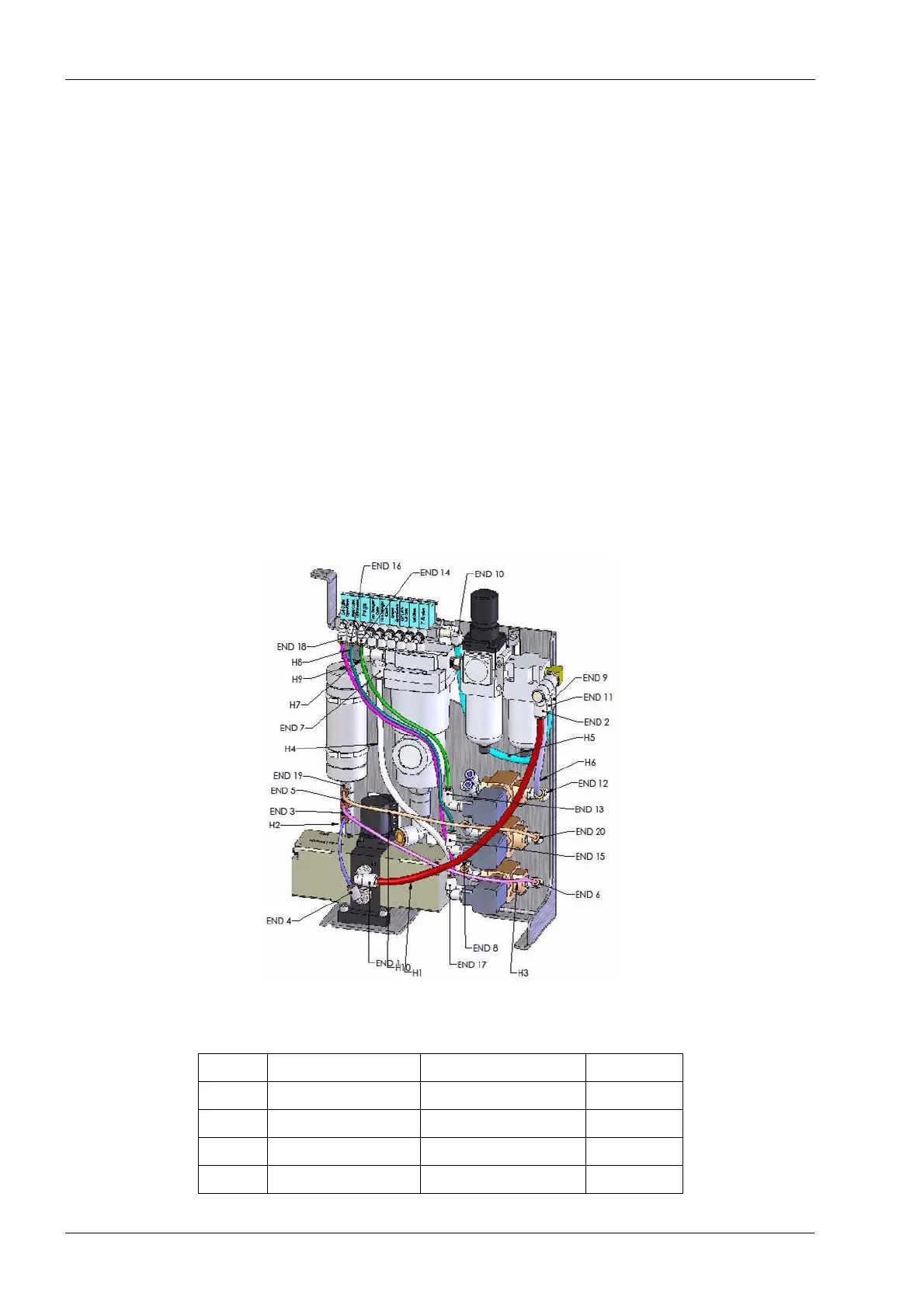

2.12.2 Pneumatics tubing routing

Should any of the tubing on the Pneumatics assembly become damaged or otherwise

require replacement the following diagram can be used for reference

• If required remove pneumatics assembly from the mill, see section 2.12.1

"Pneumatics assembly" on page 155.

• Refer to the table and image below for details on tubing sizes, lengths and routing.

Figure 169: Pneumatic tubing routing

Table 3: Pneyumatic tubing, sizes and lenghts

Tubing From/To Tubing OD (SAE) Lenght

H1 END 1 / END 2 6.35 mm (1/4”) 304 mm

H2 END 3 / END 4 3.18 mm (1/8”) 436 mm

H3 END 5 / END 6 3.18 mm (1/8”) 210 mm

H4 END 7/ END 8 6.35 mm (1/4”) 290 mm

Loading...

Loading...