Chapter B: Preventive maintenance

24 Planmeca PlanMill 40 Technical manual

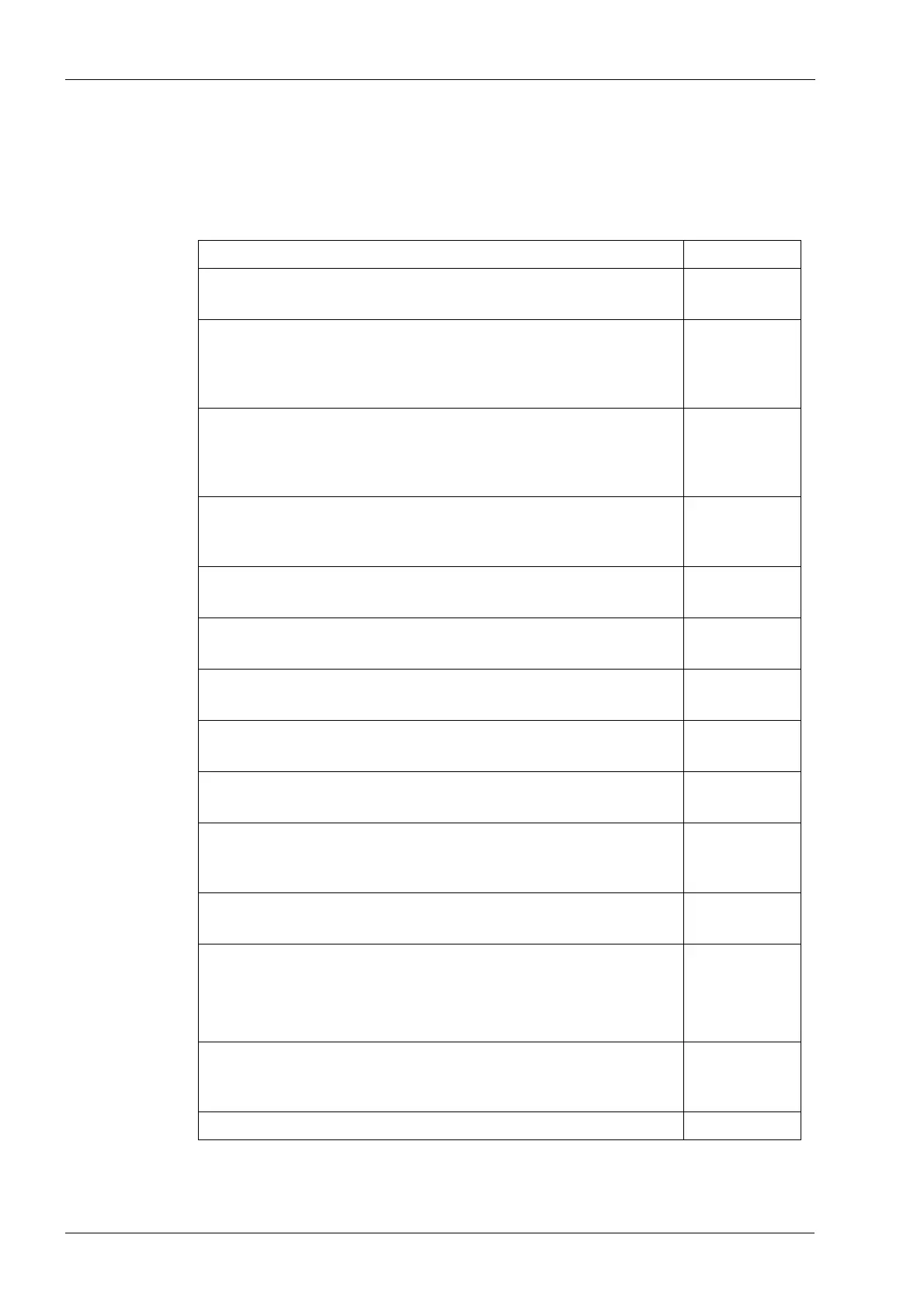

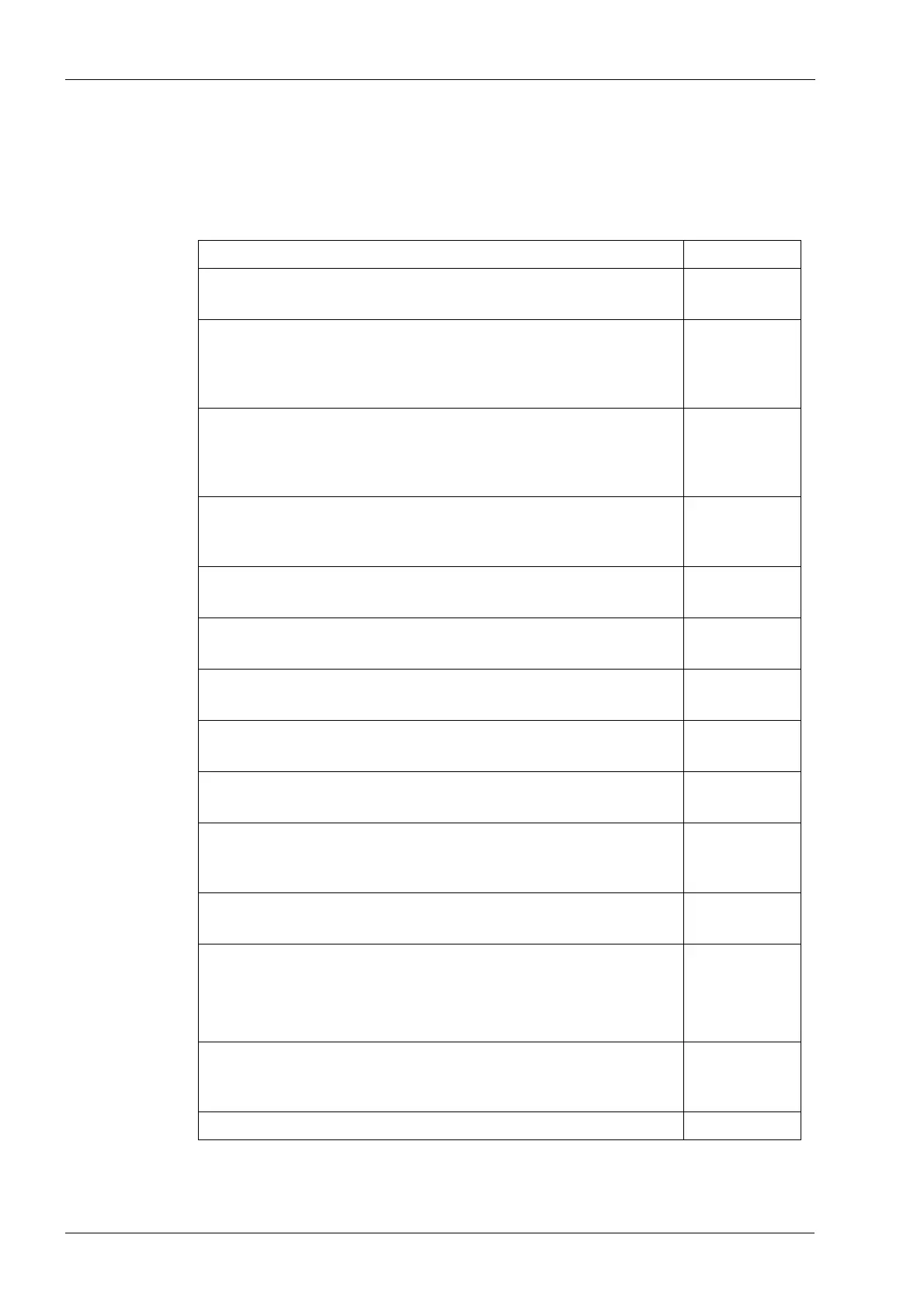

1.2 Preventive maintenance schedule

There are two types of preventive maintenance tasks, those to be made in every 4 month

and those to be made once a year.

In the following table, the preventive maintenance tasks and frequencies are listed.

Table 10: Preventive maintenance tasks and schedule

Task Frequency

Inspect pneumatic filter bowls for moisture:

• 2.1 "Inspecting pneumatic filter bowls for moisture" on page 26

4 months

Inspect profile sensor and verify proper profile sensor signal, use

mirror:

• 2.2 "Inspecting profile sensor and verifying profile sensor signal"

on page 27

4 months

Inspect tool changer 6-pack, bumper and nose seal for damage or

wear:

• 2.4 "Inspecting tool changer 6-pack, bumper and nose seal for

damage or wear" on page 32

4 months

Inspect and clean grind chamber lid/latch/interlock switches, and

verify proper operation:

• 2.5 "Verifying correct interlock switch function" on page 33

4 months

Clean fluid tank, nozzle caps, collets, mill drawer and bottom plates:

2.6 "Fluid tank cleaning" on page 34

4 months

Inspect and clean floats and suction strainer:

• 2.9 "Tank level sensors and filter basket" on page 44

4 months

Inspect and clean block orientation sensor:

• 2.10 "Orientation sensor" on page 47

4 months

Clean nozzles and collets:

• 2.7 "Cleaning collet and spindle caps" on page 35

4 months

Remove, clean and reinstall the suction tubing to the pump:

• 2.11 "Circulation system" on page 150

4 months

Verify calibration by milling a calibration bar with two new ellipsoidal

burs, and check dimensions with micrometer and refine if needed:

• 5 "Verifying calibration" on page 67

4 months

Replace collets:

• 2.7 "Cleaning collet and spindle caps" on page 35

1 year

Replace spindle packing, tool bumper and nose seal:

• 2.8 "Spindle packing" on page 41

• 2.7 "Nose seal" on page 144

• 2.9 "Tool holder" on page 147

1 year

Replace large and small o-rings on the quick release nozzle cap

adapters mounted to the spindle housings:

• 2.7 "Cleaning collet and spindle caps" on page 35

4 months /

1 year

Perform touch screen calibration, if necessary. 1 year

Loading...

Loading...