Chapter A: General and technical data 7 Mechanical design

Technical manual Planmeca PlanMill 40 17

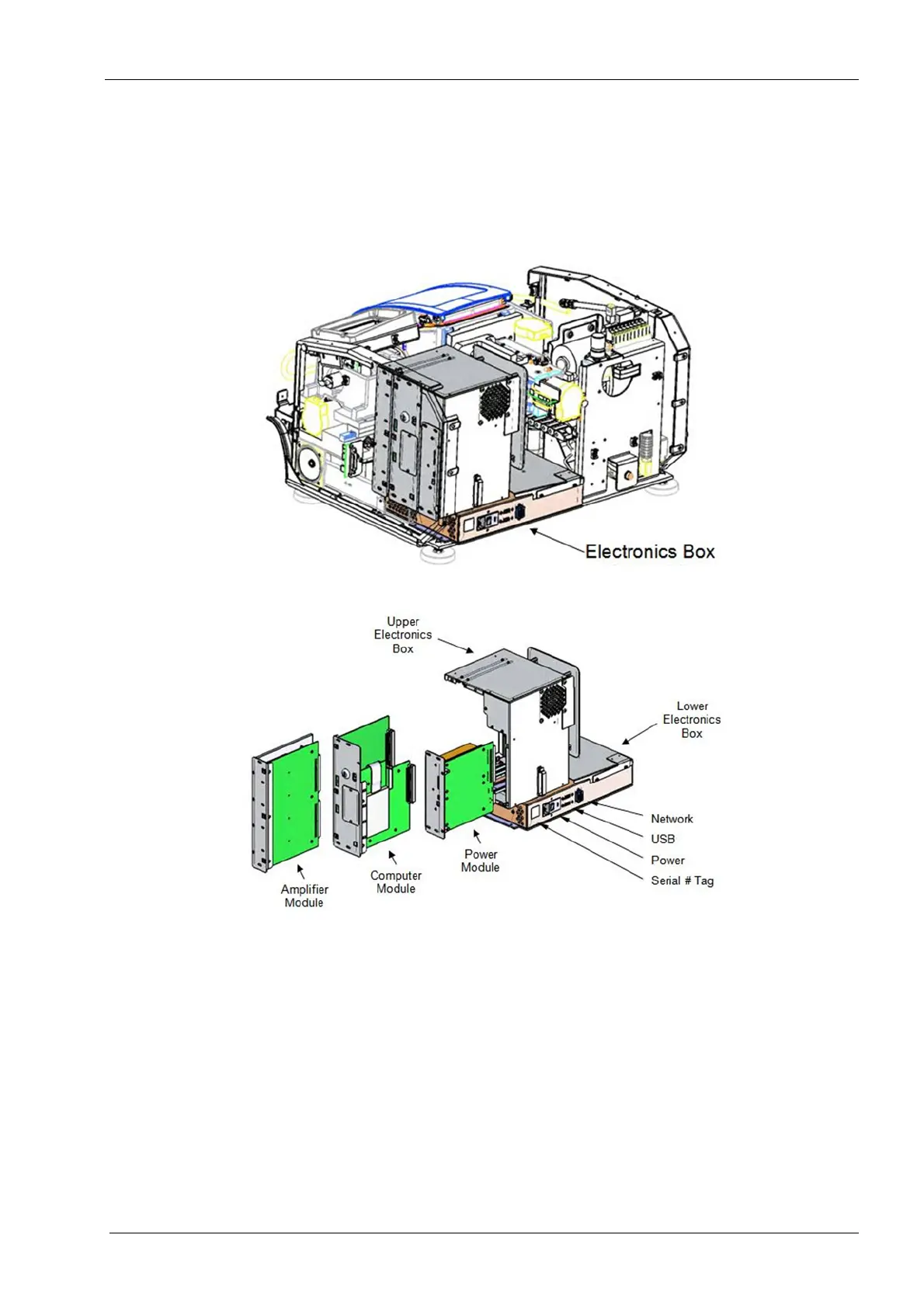

All the computer related components (boards, touch display, hard drive, fans, etc.) are

powered by the power supply module. Similar to the other two modules, this unit slides

into the upper box and obtains all required connections via the backplane board.

An LCD touch display is connected to the electronics box via a video cable. This touch

display provides the user interface to the PlanMill 40 software and other operating system

features while eliminating the need for either a keyboard or mouse.

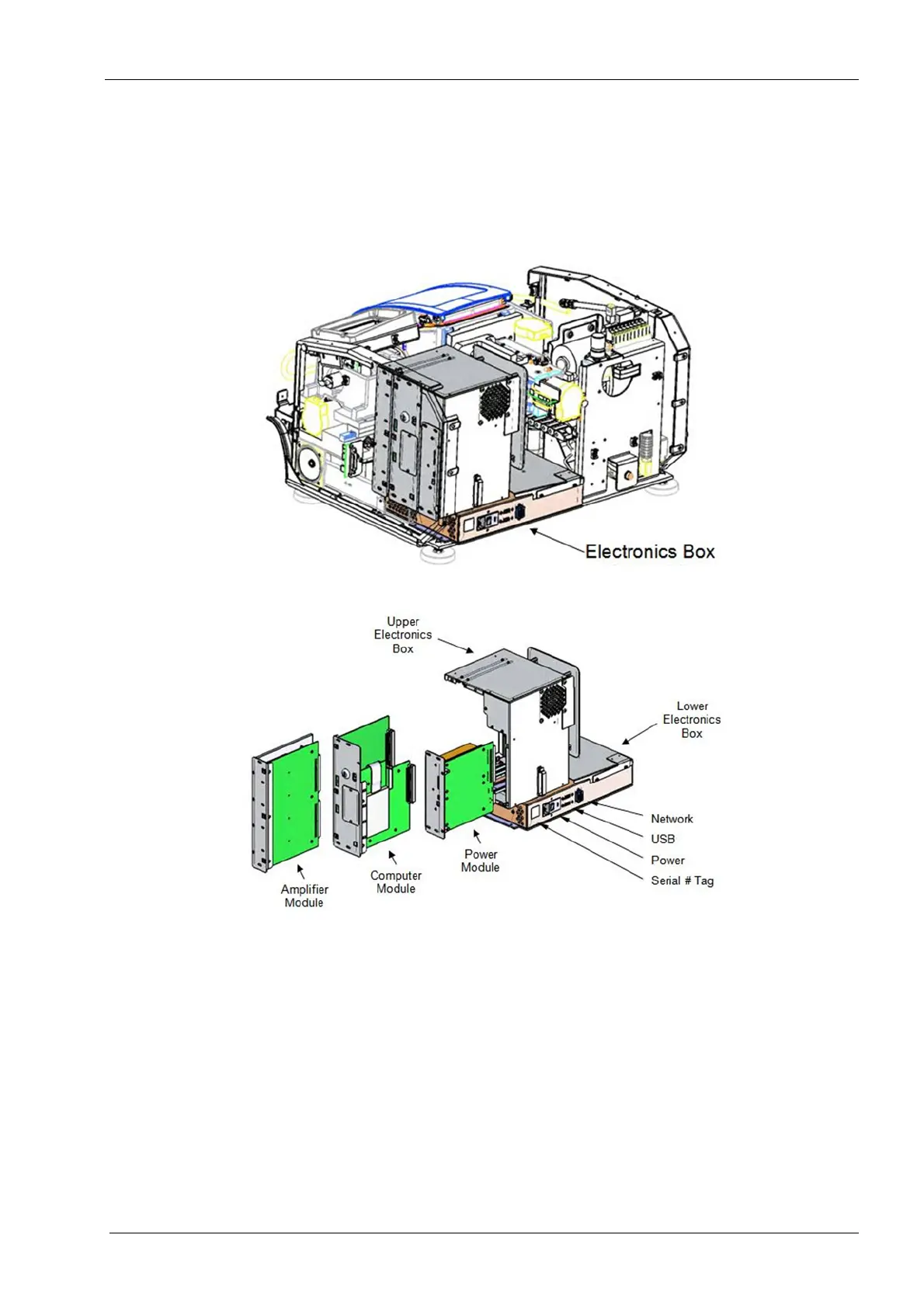

Figure 2: Electronics box

Figure 3: Electronics box assembly

7.3 Circulation system

Milling fully sintered ceramic requires a wet grind process. This mill utilizes a circulation

system to deliver and recycle a water-based coolant to the grinding surface. The major

components in the circulation system include the fluid tank, pump assembly, sensors,

plumbing, and coolant. In addition to cooling and lubricating the grinding surface, the

coolant washes away debris and keeps the tools clean. As mentioned previously, the

coolant is delivered through the spindle housing to the tip of the grinding tools where it is

contained by the grind chamber. The coolant exits the bottom of the grind chamber and

enters the fluid tank.

Loading...

Loading...