Chapter E: Basic repair procedures 2 Basic repair procedures

Technical manual Planmeca PlanMill 40 163

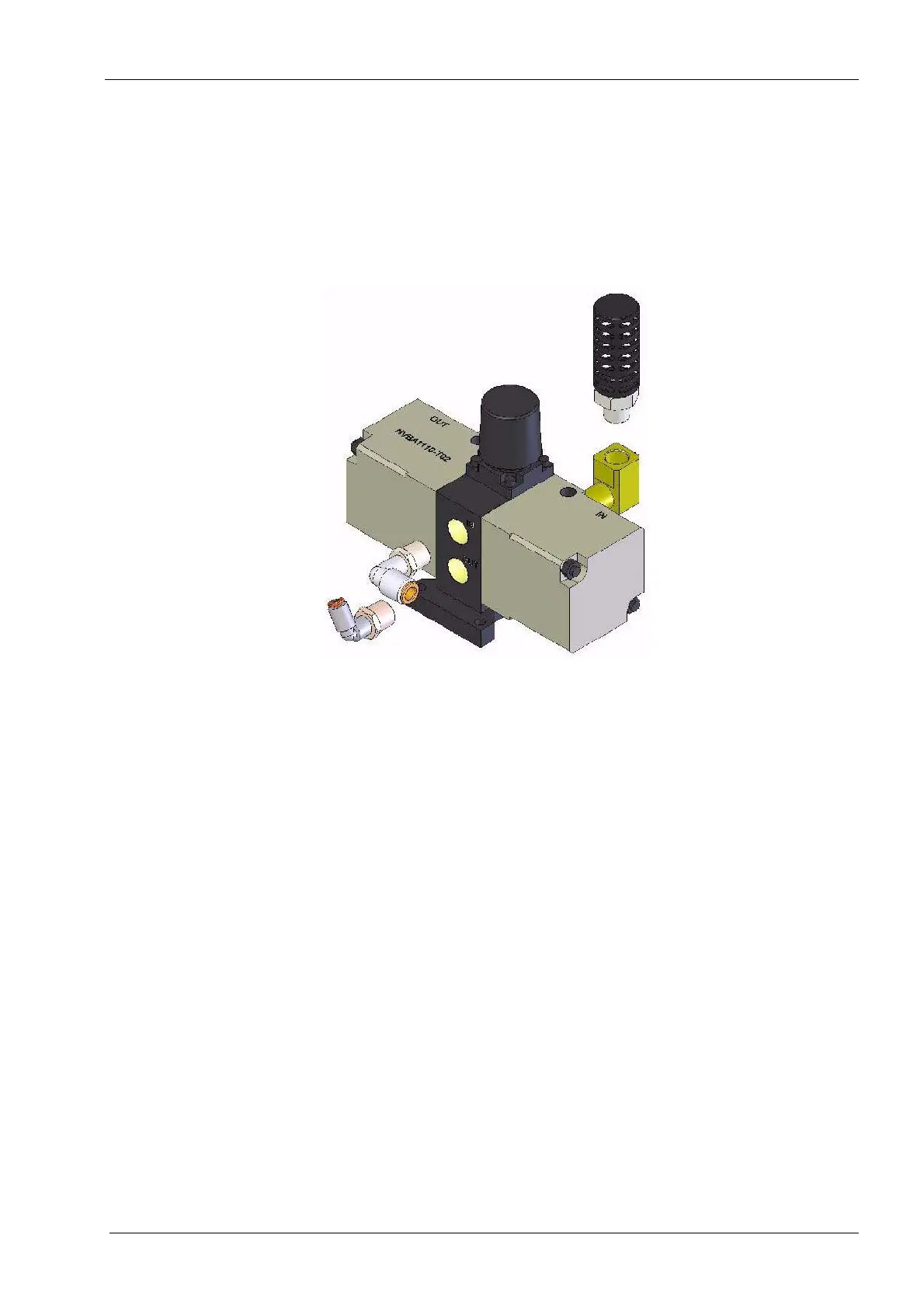

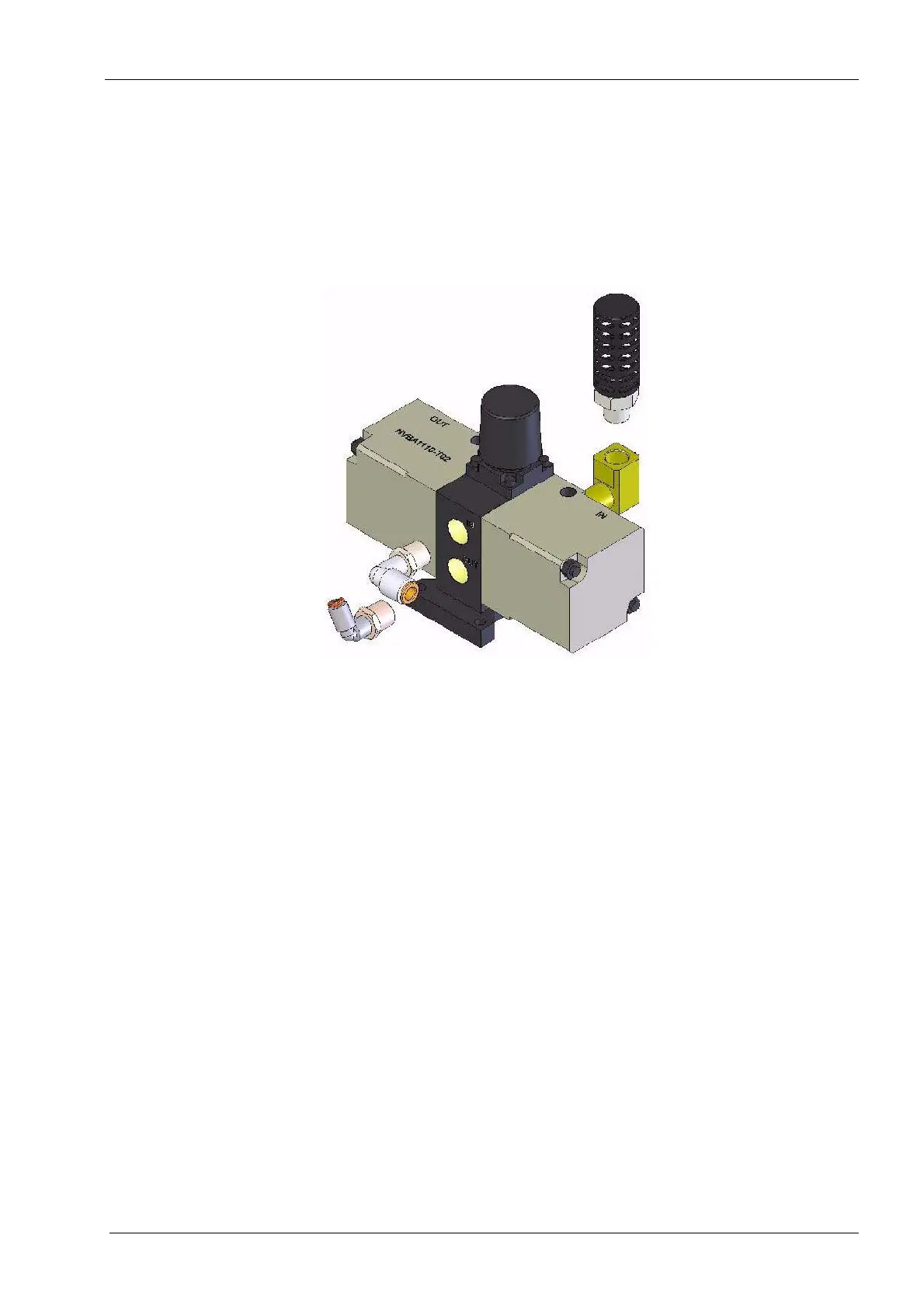

2.12.6 Pressure multiplier

The Pressure Multiplier is used to increase the incoming air pressure from 3.45 bar to 6.9

bar (50 psi to 100 psi) in order to operate the auto-chucking collet mechanisms in spindles.

Tools required

• metruc Allen key set

Figure 174: Pressure multiplier

Removal

1. Remove the top cover and left side panel, see section 2.1 "Mill covers" on page 94.

2. Tag and disconnect the upper 6.35 mm (¼”) supply tube from the pressure multiplier

fitting.

3. Tag and disconnect the lower 3.175 mm (1/8”) discharge tube from the pressure

multiplier fitting.

4. Remove the (4) screws securing the pressure multiplier to the pneumatics assembly.

5. Lift free from the assembly.

Install

1. Position regulator/separator assembly in place on pneumatics assembly bracket and

secure with (4) mounting screws.

2. Connect pneumatic tubes to fittings on pressure multiplier.

3. Reconnect the air supply line and apply pressurized air.

4. Maximize pressure multiplier output by lifting and rotating regulator knob (on the

pressure multiplier) clockwise until it stops then back off approximately ¼ turn. This

will double the incoming (3.45 bar/50 psi) air to provide 6.9 bar (100 psi) to the

spindles for opening the collets.

5. Verify that there are no air leaks.

6. Reinstall rear cover, side panel and top cover, see section 2.1 "Mill covers" on page

94.

Loading...

Loading...