Chapter D: Troubleshooting

Technical manual Planmeca PlanMill 40 73

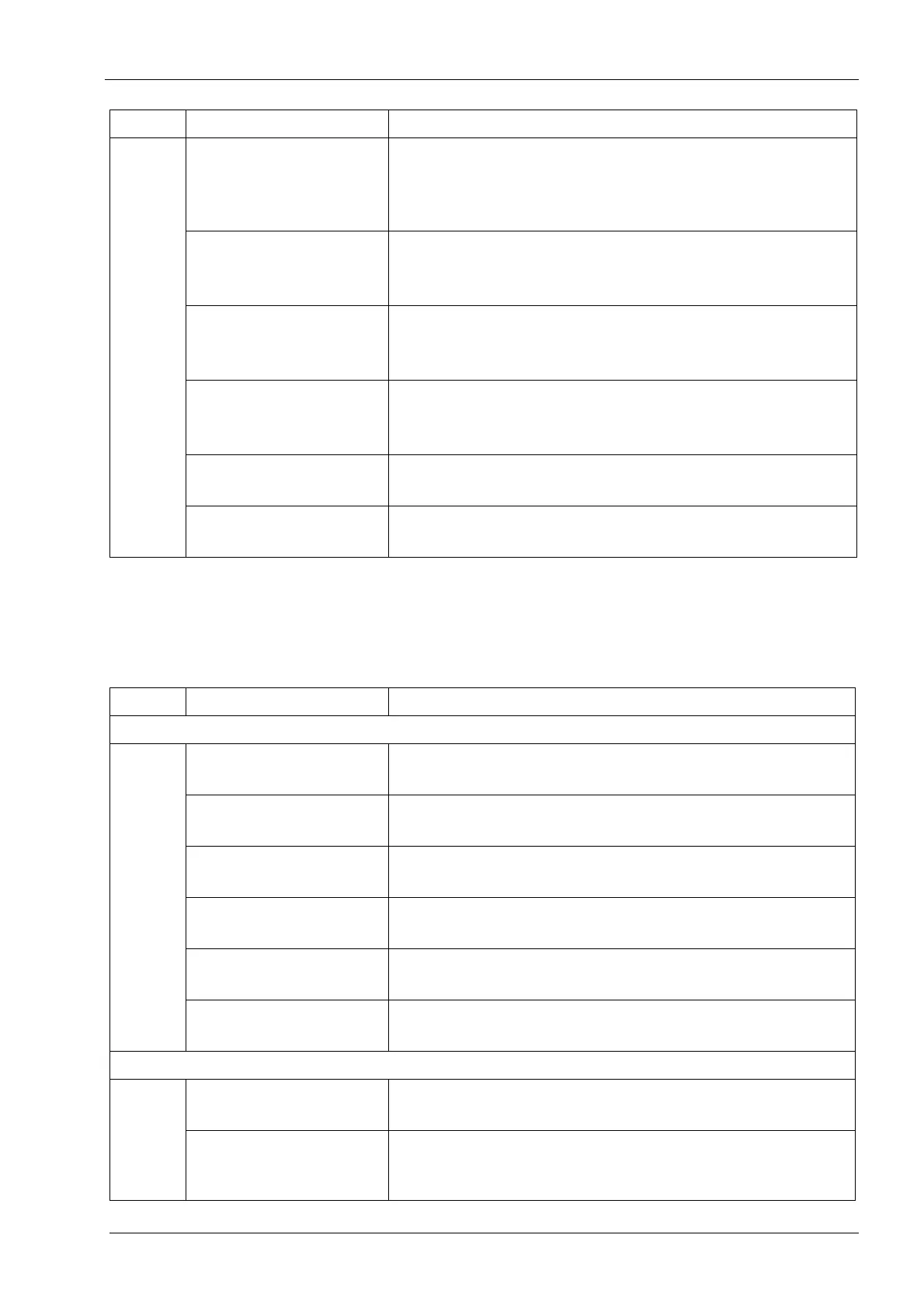

1.2 Spindles problems

Table 14: Spindles problems

Damaged profile sensor Replace profile sensor and recalibrate:

2.10 "Profile sensor" on page 148

2.2 "Inspecting profile sensor and verifying profile sensor signal" on

page 27

Poor tool changer

calibration

Reseat tool holder then recalibrate:

2.9 "Tool holder" on page 147

Chapter C: "Calibration" on page 49

Damaged tool holder Reseat tool holder then recalibrate:

2.9 "Tool holder" on page 147

Chapter C: "Calibration" on page 49

Damaged tool changer arm

(sensor slot)

Replace tool changer, then recalibrate:

2.4 "Tool changer" on page 127

Chapter C: "Calibration" on page 49

Defective calibration

equipment

Replace calibration equipment:

1.1 "Tools required" on page 50

Motion system problem Test motion system:

2.4 "Troubleshooting mill motion system" on page 89

Symptom Problem Solution

Spindle speed error

Damaged nozzle cap Replace nozzle cap:

2.7 "Cleaning collet and spindle caps" on page 35

Defective spindle Replace spindle:

2.13.9 "Spindle and spindle motor" on page 182

Defective 48V power supply Replace lower E-box:

2.2.9 "Lower electronics box (E-box)" on page 113

Defective spindle motor Replace spindle motor:

2.13.9 "Spindle and spindle motor" on page 182

Defective CPU module Replace CPU module:

2.2.2 "CPU module" on page 102

Defective spindle Replace spindle:

2.13.9 "Spindle and spindle motor" on page 182

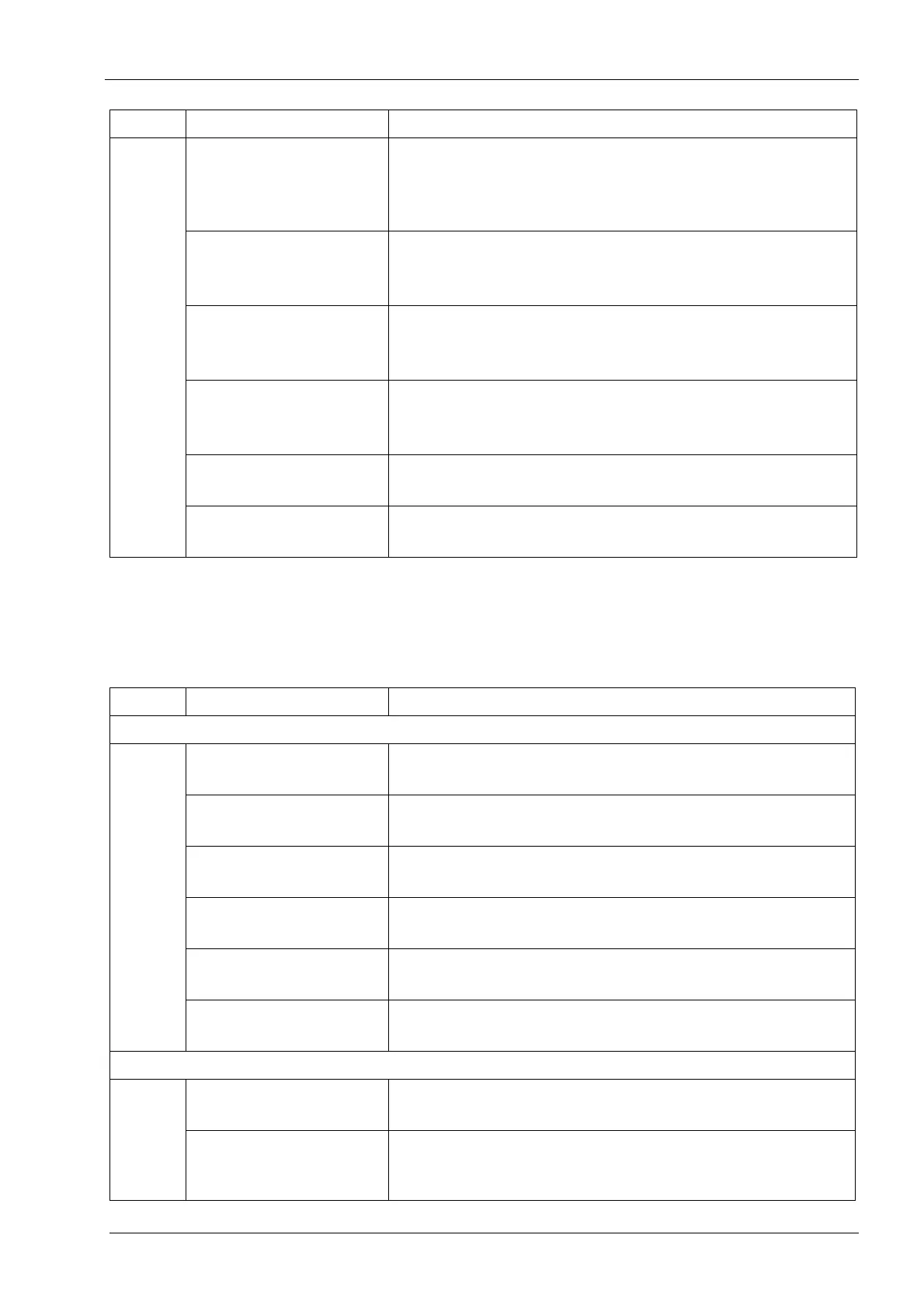

Noisy spindle

Defective spindle motor Replace spindle motor:

2.13.9 "Spindle and spindle motor" on page 182

Tool is stuck/jammed in

collet

Use "stuck tool" removal tool in tool kit and replace collet:

2.7 "Cleaning collet and spindle caps" on page 35

Symptom Problem Solution

Loading...

Loading...