Chapter E: Basic repair procedures 2 Basic repair procedures

Technical manual Planmeca PlanMill 40 175

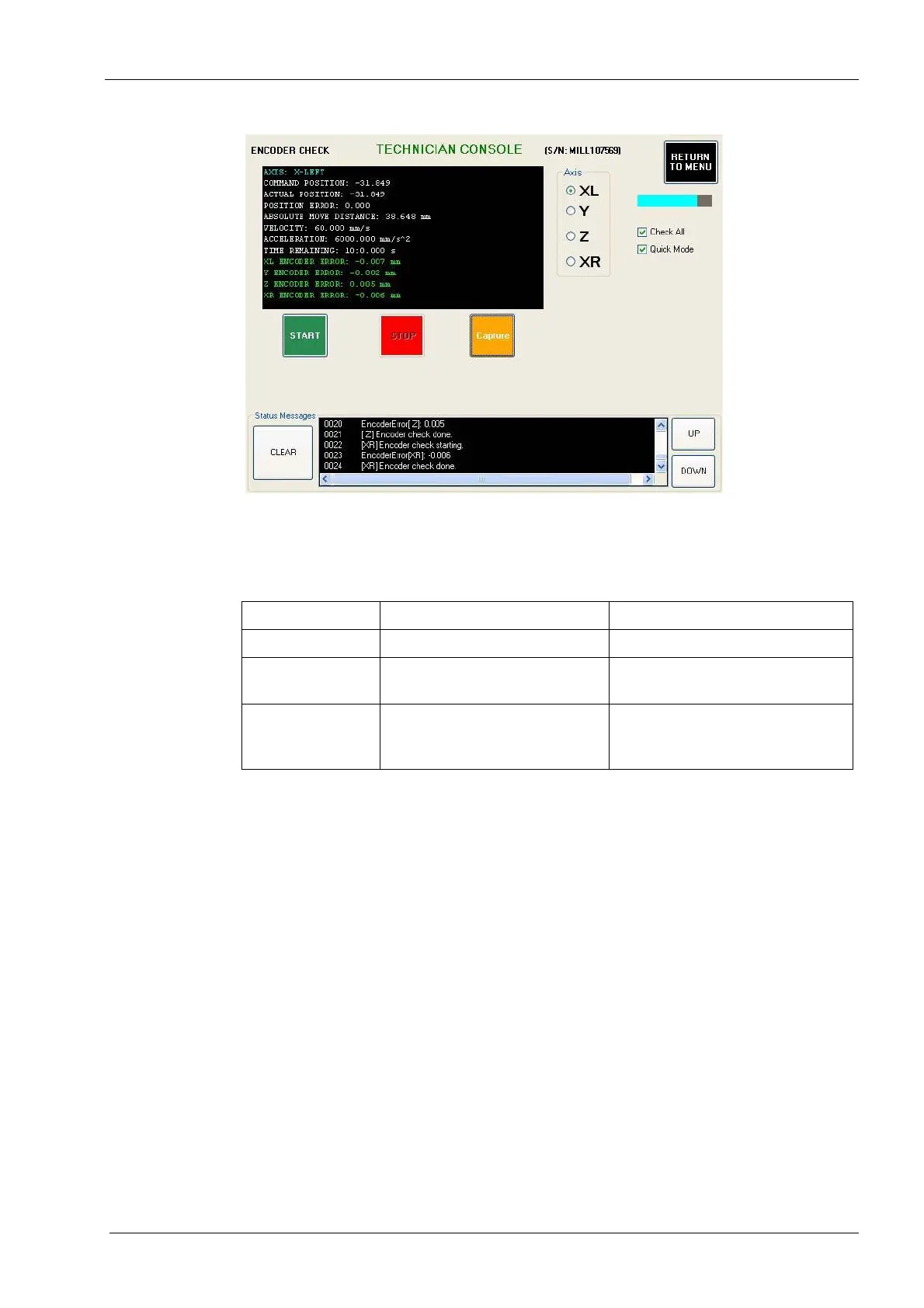

Figure 188: Encoder check

8. Select the Axis:Z. Unselect Check All. Select Quick Mode. Select the START button.

After a few minutes, the encoder error for the Z-axis will be printed in the text box in

the upper left corner of the screen. See the table below for encoder error guidelines.

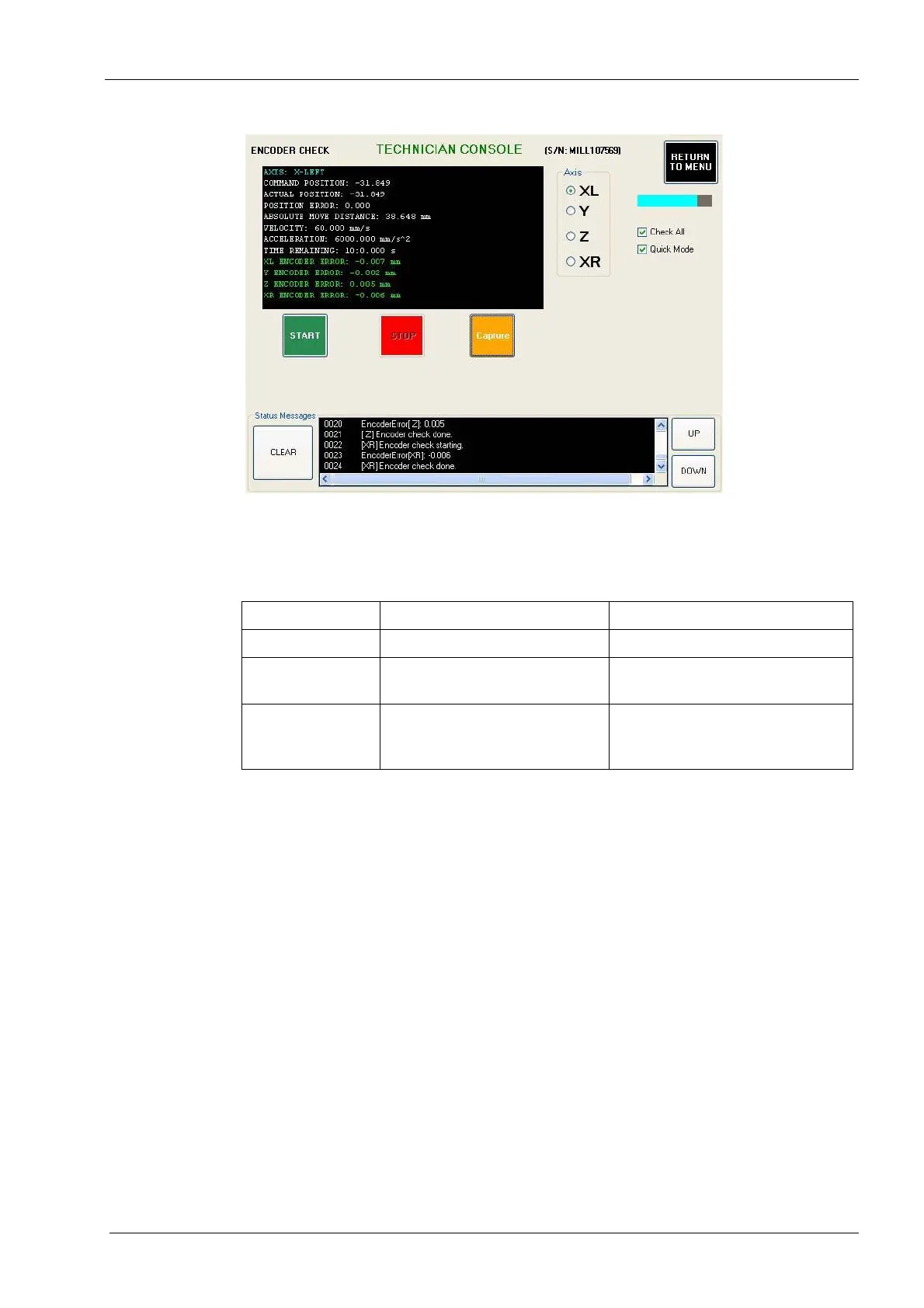

Table 6:

Encoder error guidelines

2.13.4 Home and limit sensors identification

Home and limit sensors are located on each of the 4 axes. The sensors are an optical

design and are triggered by interrupting an infra-red optical beam between the two posts

of the sensor. Each axis uses a metal sensor flag mounted on the respective carriage to

trigger the sensor. The flag is positioned such that the sensor triggers approximately 1-2

mm before hard-stop end of travel for the axis. Each axis has one home sensor and one

limit sensor; the home sensors are located as follows:

• L and XR -axes are fully retracted from the origin to the outsides of the machine

• Y-axis is fully retracted from the origin to the back of the machine

• Z-axis is fully down

The limit sensors are located at the opposite end of travel on each axis and are as follows:

• L and XR -axes are fully in-board past the origin, with tools installed the tips of each

tool barely clears the nozzle cap on the opposite spindle.

• Y-axis is fully forward past the origin.

• Z-axis is fully up.

See appropriate procedure following for sensor to be replaced.

Encoder error Problem Solution

0 to 0.015 Acceptable encoder error. No action required.

0.015 to 0.100 Weak servo, defective encoder,

and/or defective cable.

Replace servo motor and retest.

Replace cable if needed.

0.100 or greater Loose motor coupling, defective

encoder, and/or defective

cable.

Tighten motor coupling and retest.

Replace servo motor and/or cable

if needed.

Loading...

Loading...