4 Origin calibration Chapter C: Calibration

60 Planmeca PlanMill 40 Technical manual

4 Origin calibration

The origin of the mill is a point in space which defines X = 0, Y = 0, and Z = 0 for each of

the axes and the toolpath used to grind the dental restorations. This point is located on the

front face of a mandrel (without a block) and centered both horizontally and vertically. We

use the tip of the tool in the left spindle to define this point. The tip of the right tool is simply

offset from this origin by Y-offset and Z-offset values. We utilize an automated procedure

to determine the origin and offset values.

The principal of operation for the Auto-touch calibration procedure is based on electrical

continuity. The calibration mandrel is positioned in the mandrel holder on the mill. The

cylindrical end is electrically isolated from the mandrel portion which locks into the holder.

Additionally, the calibration pins are installed into the spindles. Electrical leads from the

Auto-touch calibration box are connected to each of the calibration pins and the calibration

mandrel. The Auto-touch calibration box is then connected to the mill electronics box via a

USB connection. A continuity signal is monitored by the upper level software through this

USB connection. Critical dimensions of the components in the calibration kit are entered

and saved in the PlanMill 40 software to minimise any errors associated with

manufacturing variations in the calibration kit components. A specialised calibration

sequence is initiated in the software once the connections have been made. This

sequence consists of a number of probing operations in which the milling unit precisely

locates the position of the calibration mandrel. This sequence is fully automated and

simply requires the removal of the components upon completion.

The result of the auto-touch calibration procedure is that the X, Y, and Z coordinates for

the origin to the left spindle are now defined. Specifically, these coordinates are the

physical distances from the home sensors on each of the axes to the origin. Additionally,

the Y-offset, Z-offset and indirectly the X-tools, Delta-X’s define the right tools position

relative to that origin.

Performing this calibration procedure will necessitate performing the rest of the calibration

steps, listed in 1 "Overview" on page 49.

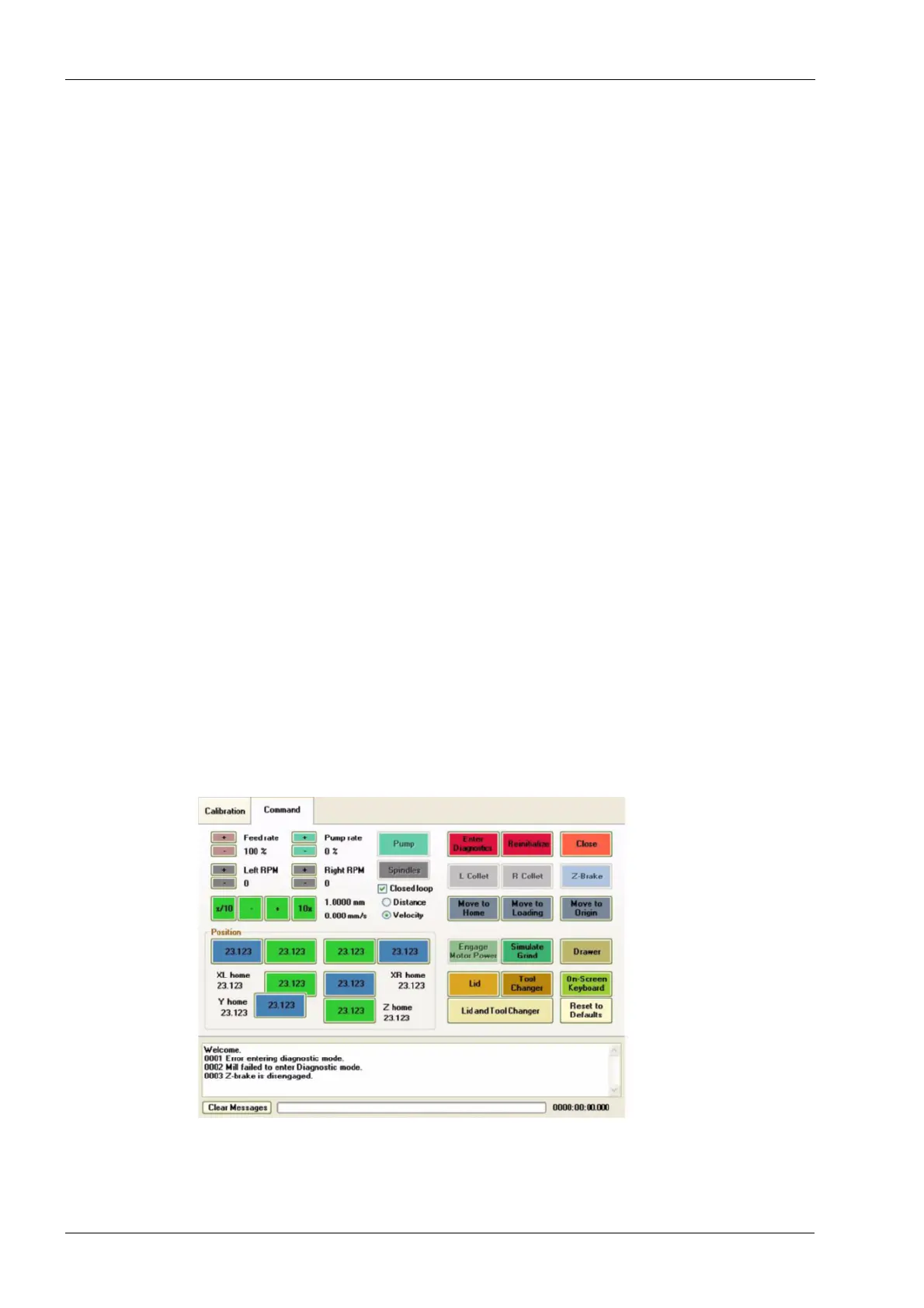

1. Touch the Calibration tab.

Figure 52: Touch Calibration tab

2. Locate the (Step3) Origin box and touch the drop down arrow.

3. Then select auto_touch from the drop down list.

Loading...

Loading...