2 Troubleshooting Chapter D: Troubleshooting

92 Planmeca PlanMill 40 Technical manual

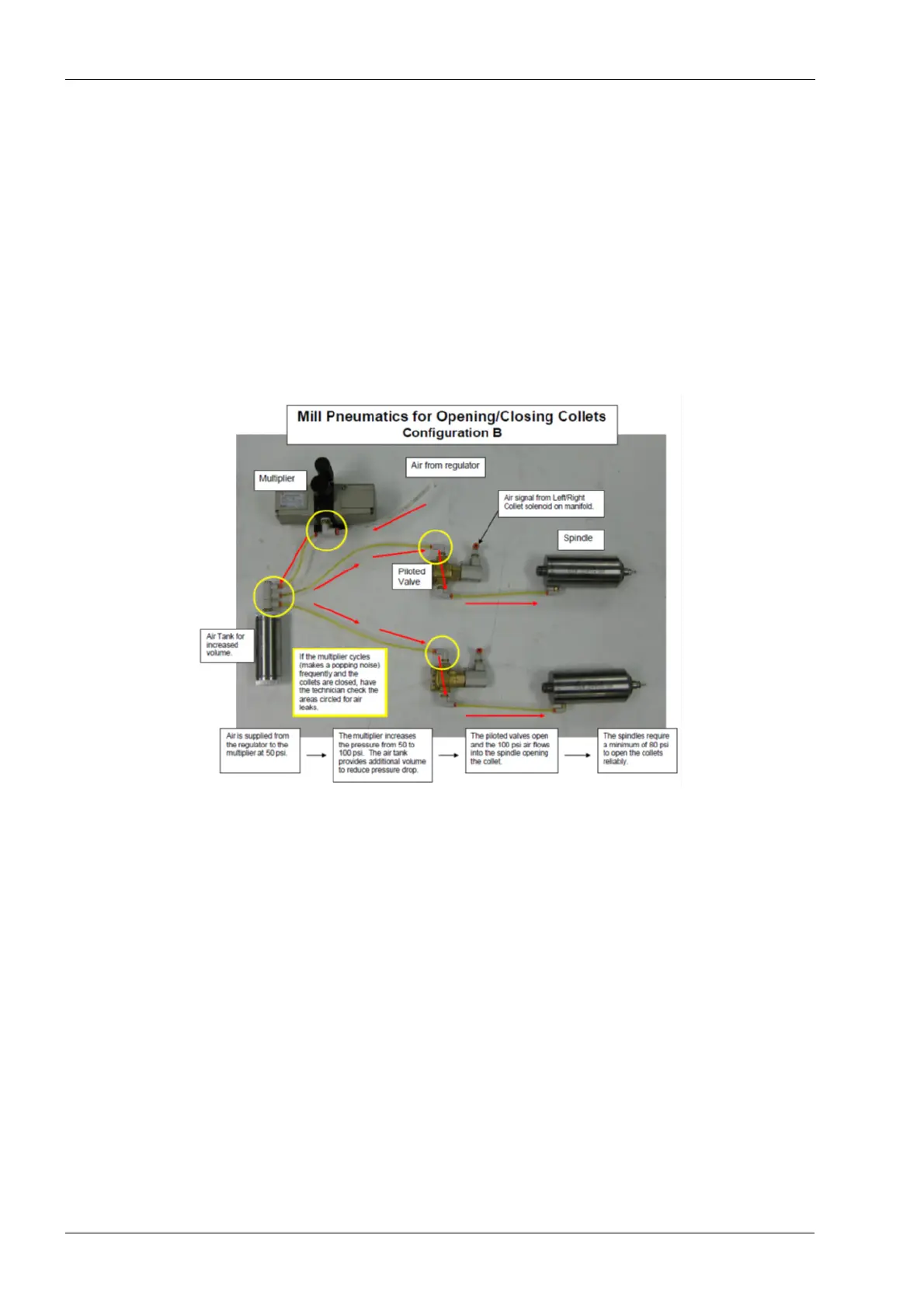

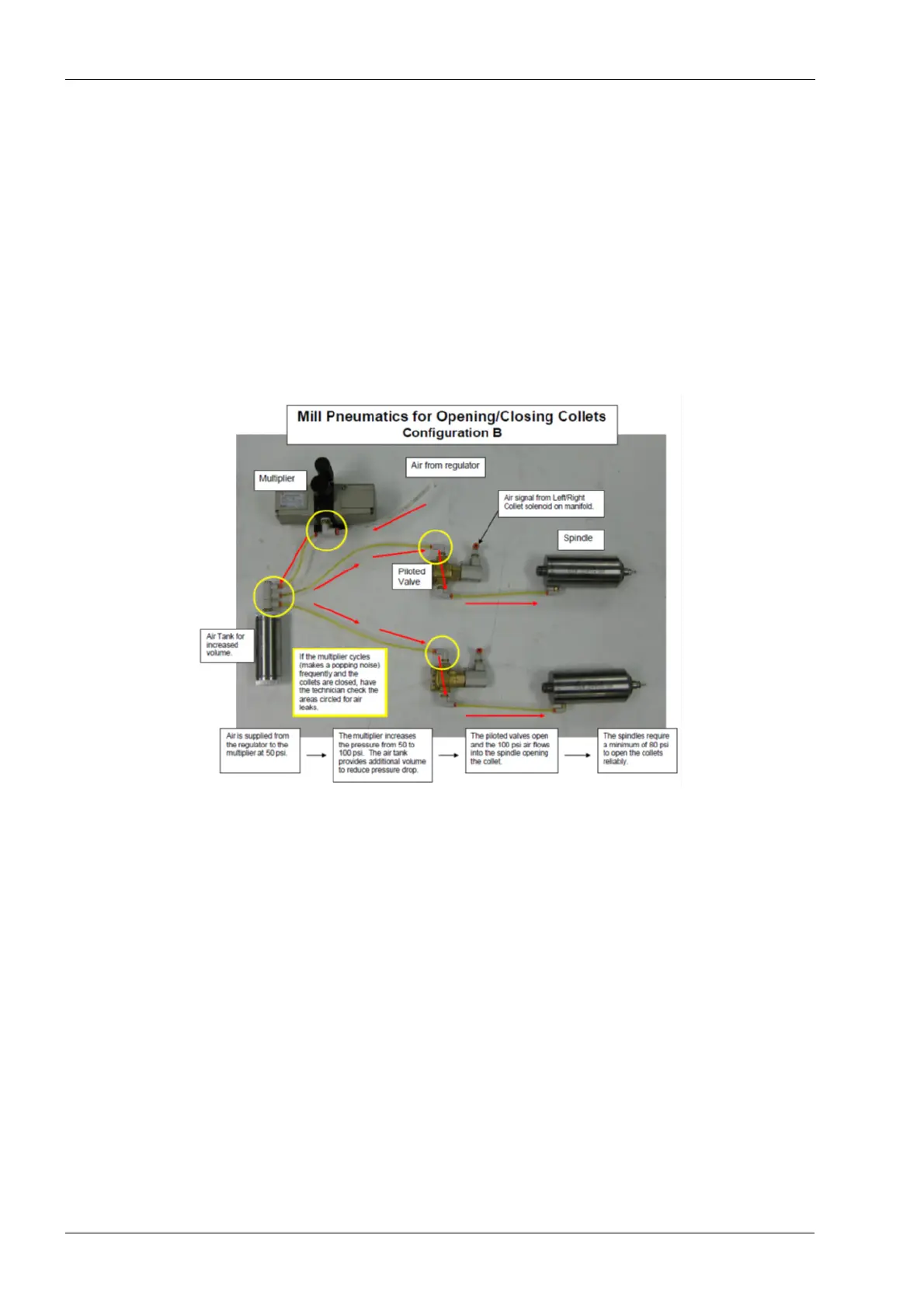

2.5 Troubleshooting popping noise

1. If a popping noise occurs frequently (once or more every minute) and occurs during

milling and when at idle, it is most likely the pressure multiplier cycling due to a small

air leak in the pressure multiplier circuit.

2. Generally, the popping noise coming from the pressure multiplier, and is simply an

annoyance to the customer. The mill will function properly if the multiplier pops at idle

or during milling. The popping noise is due to an air leak in the pressure multiplier

circuit. The solution is to find and repair the leak. The technician can spray a soapy

water solution onto each of the one-touch fittings to check for leaks. If none of the

one-touch fittings are leaking, the leak can be coming from the internal seals in one of

the piloted valves, the pressure multiplier, or one of the spindles.

3. See the following flow diagram for instruction on which fittings to test for air leaks.

Pneumatic circuit for collet operation

Loading...

Loading...