Chapter D: Troubleshooting

78 Planmeca PlanMill 40 Technical manual

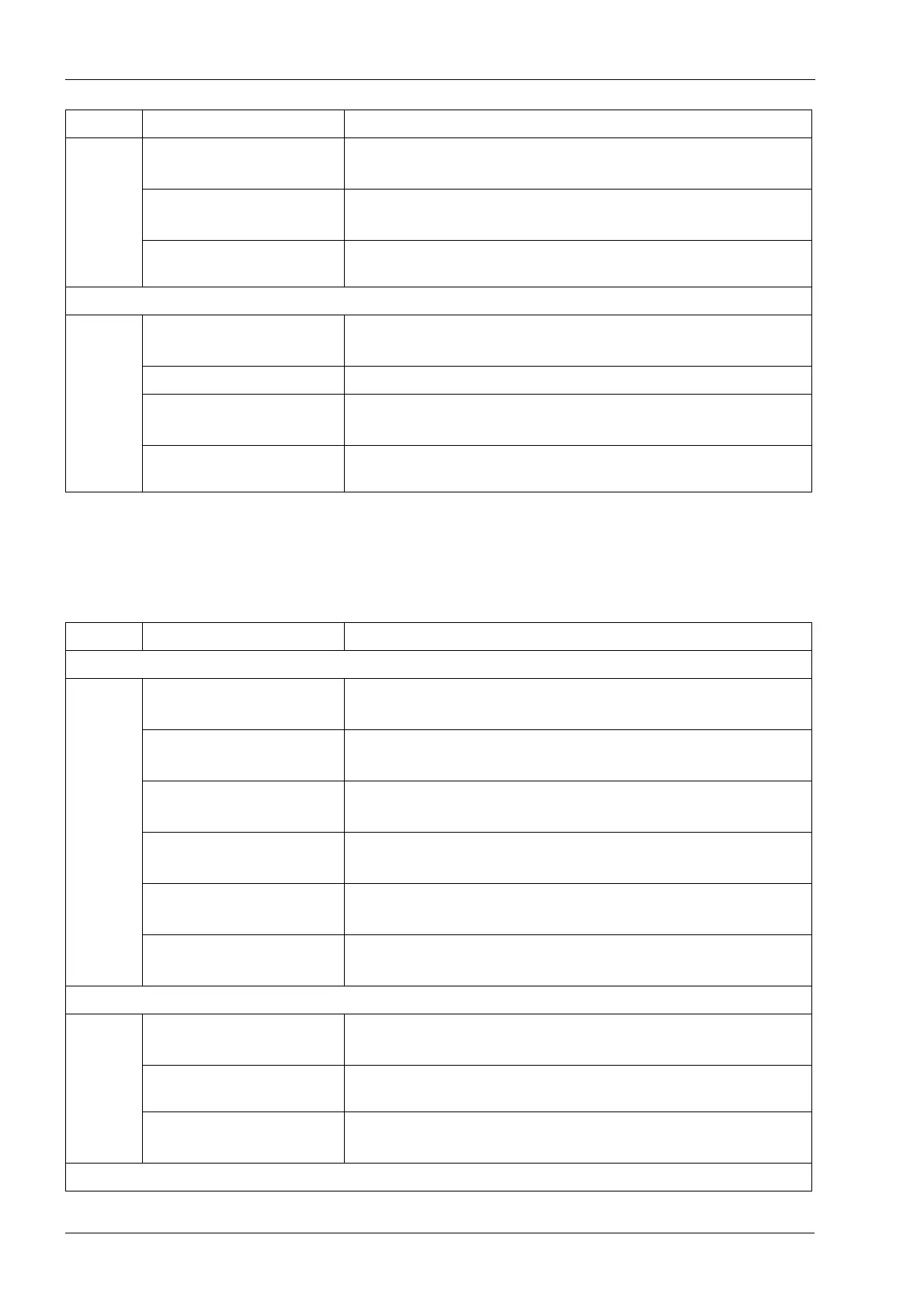

1.4 Mandrel holder problems

Table 16: Mandrel holder problems

Top cover pressed against

lid

Adjust top cover away from lid:

2.1.1 "Top cover" on page 94

Defective lid latch assembly Replace lid latch assembly:

2.3.3 "Lid latch" on page 123

Lid pneumatics badly

adjusted

Adjust lid pneumatics.

Coolant leaks out around the lid

Upper nozzle cap nozzles

blocked with debris

Clean nozzle cap nozzles:

2.7 "Cleaning collet and spindle caps" on page 35

Excessive foaming Add defoamer to coolant.

Excessive foaming Clean tank, suction strainer, suction basket, and nozzle caps:

2 "Maintenance procedures" on page 26

High concentration of

coolant in tank

Empty tank and add coolant per instructions on bottle label.

Symptom Problem Solution

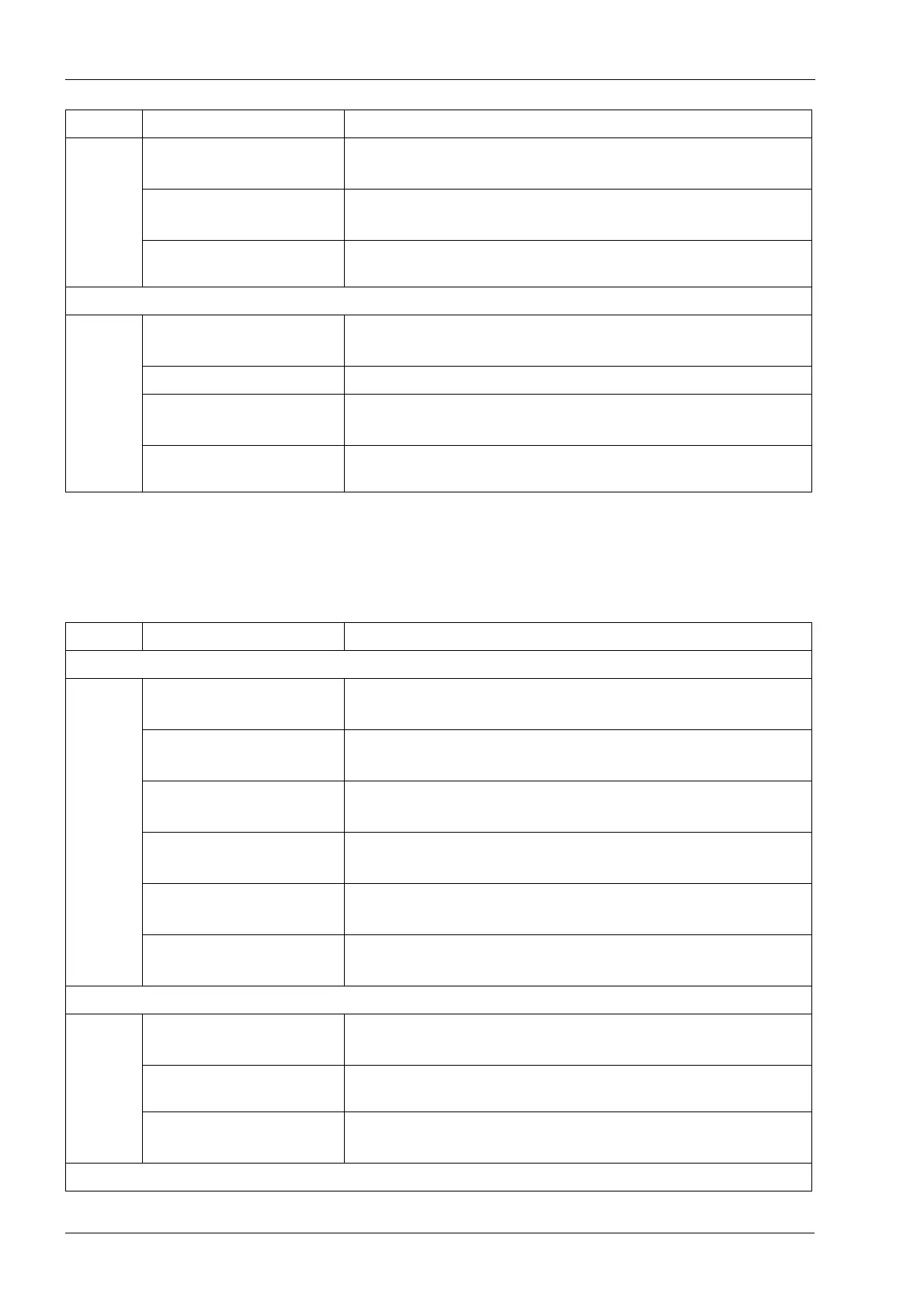

Block orientation detection doesn't work

Debris clogging tubing

inside mandrel holder

Remove debris:

2 "Maintenance procedures" on page 26

Low air pressure Set air pressure regulator at 3.45 - 3.80 bar (50 - 55 psi):

2.12.5 "Regulator, filter and water separator" on page 161

Defective tubing inside

mandrel holder

Replace tool changer assembly:

2.4 "Tool changer" on page 127

Defective CPU module Replace CPU module:

2.2.2 "CPU module" on page 102

Defective air pressure

switch (inside tool changer)

Replace tool changer assembly:

2.4 "Tool changer" on page 127

Defective tool changer I/O

cable

Replace tool changer I/O cable:

2.4 "Tool changer" on page 127

Mandrel cam is hard to turn

Debris inside mandrel

holder

Remove debris

2 "Maintenance procedures" on page 26

Damaged/worn mandrel

cam

Replace mandrel cam.

Damaged/worn mandrel

holder

Replace tool changer assembly:

2.4 "Tool changer" on page 127

Mandrel cam doesn't clamp block securely

Symptom Problem Solution

Loading...

Loading...