Chapter D: Troubleshooting 2 Troubleshooting

Technical manual Planmeca PlanMill 40 91

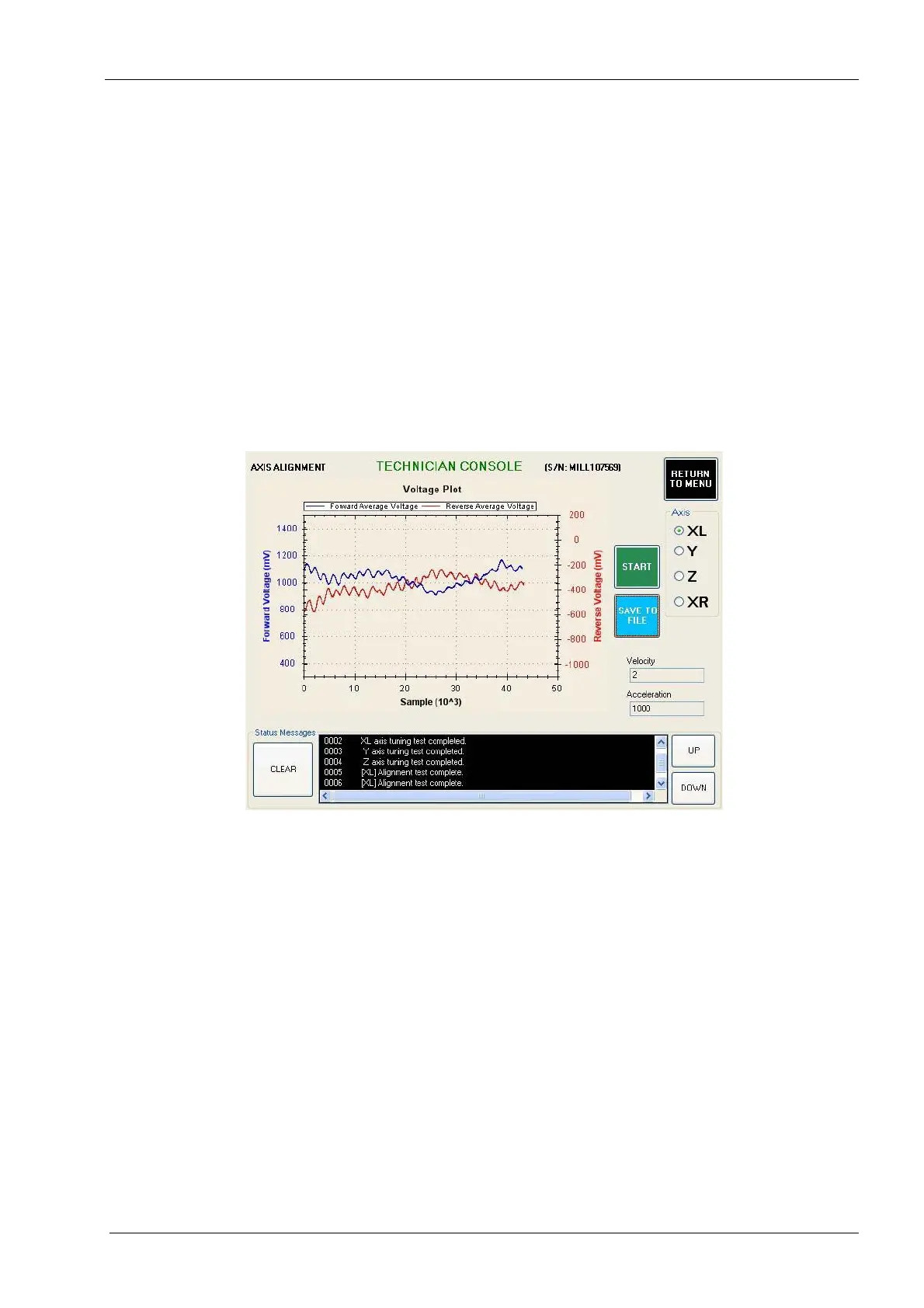

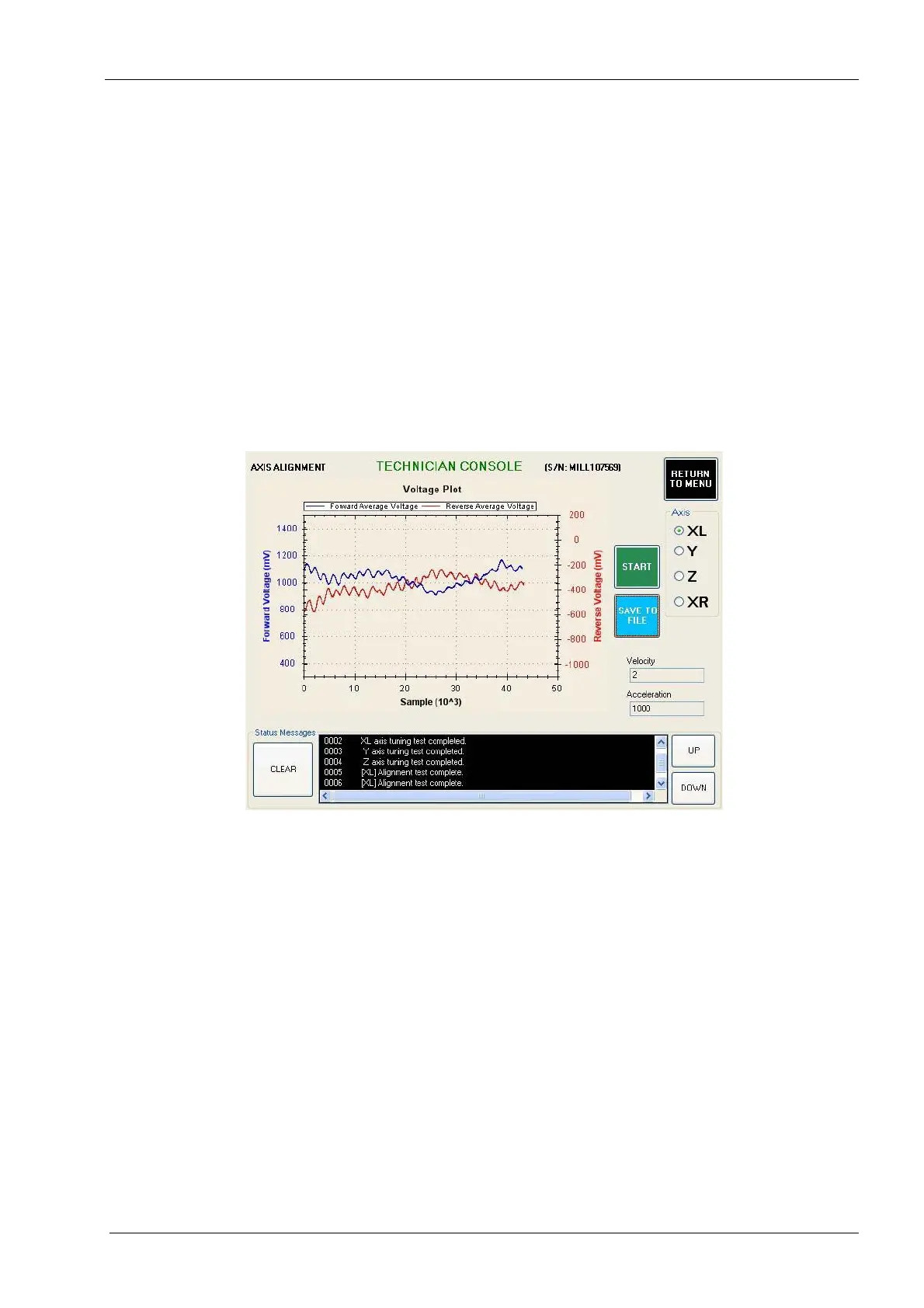

9. Navigate to: Technician Console -> Motion Diagnostics -> Axis Alignment.

10. Select the axis to test and then select the Start button. Evaluate the graph using

guidelines shown below. Two main characteristics to look for in the axis alignment

graph are:

• Both the forward and reverse graphs (blue and red respectively) should be close

to horizontal. A graph that has a steep upwards or downwards slope is an

indication of an axis assembly that is out of alignment and may need to be

repaired for optimal performance.

• Neither graph should exceed 4volts (4000mV). A graph that exceeds 4volts is an

indication of an axis assembly that is out of alignment and may need to be

repaired for optimal performance.

Dry and/or old spindle housing rope packing on the XL and/or XR axis can affect the results

of the axis alignment test.

Figure 70: Example of GOOD axis alignment graph

11. If the axis alignment graph is good but that axis failed the servo diagnostics test, then

replace the servo motor and/or cable and repeat the servo diagnostics test. If the axis

alignment graph is bad, realign the axis assembly and retest.

12. In the event all four axes have passed all the tests described so far and an issue with

the function of the mill still exists, it is probable that the problem is intermittent and

therefore will be difficult to diagnose. Following is a list of components that when

defective can cause the motion system to fail. Consider each of these components

when further troubleshooting a motion system issue.

• lid interlock switches/cable

• home/end limit sensors and/or cables

• CPU module (motion controller, interface PCB, hard drive)

• lower E-box (48 volt power supply)

• power module

• Amp module

• E-box backplane PCB

• servo motor/cable

Loading...

Loading...