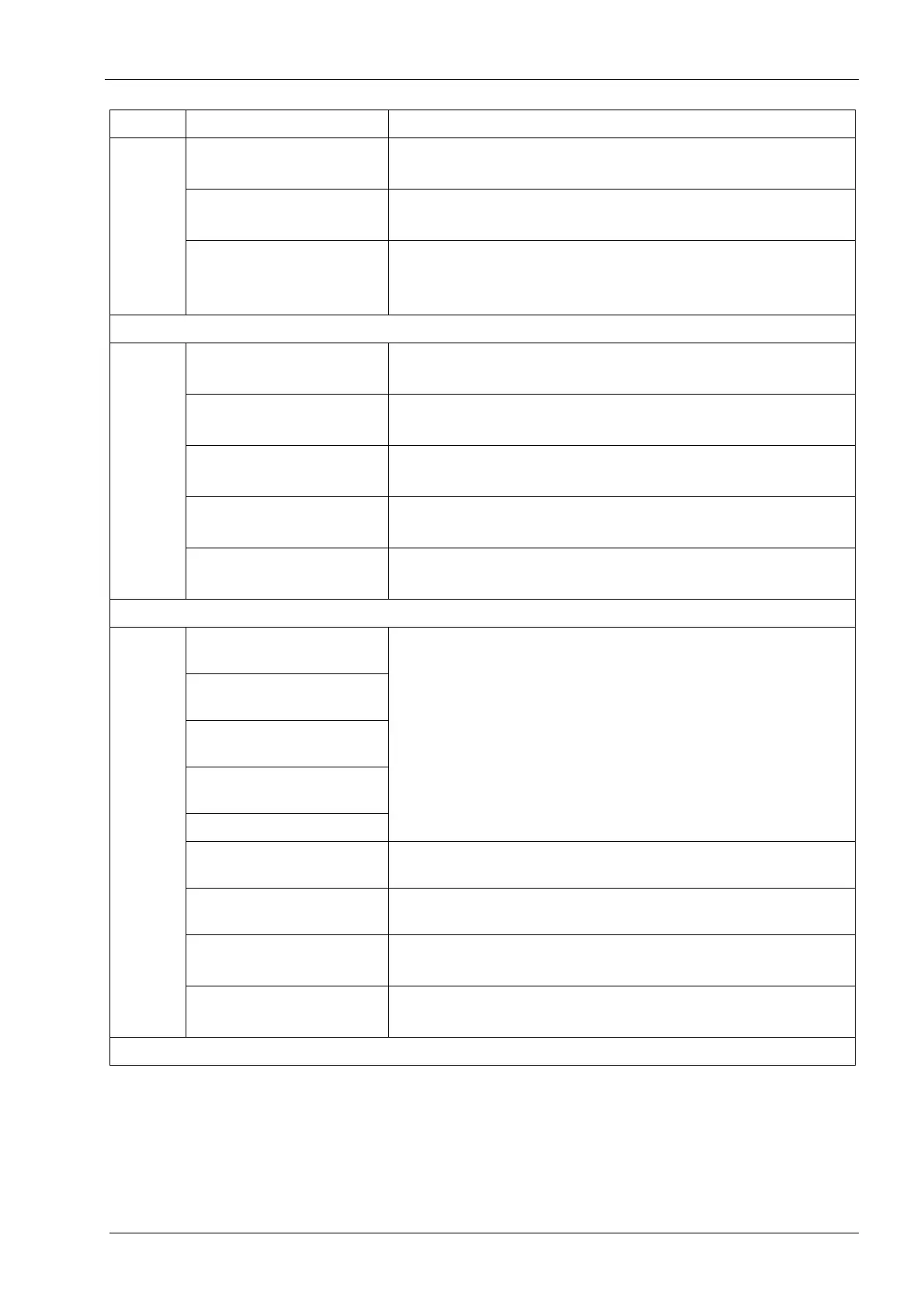

Chapter D: Troubleshooting

Technical manual Planmeca PlanMill 40 75

Collet was over-tightened

during last install

Attach 6 mm Allen key to collet removal knob for added leverage:

2.7 "Cleaning collet and spindle caps" on page 35

Collet is in the closed

position

Open collet first, then attempt to remove collet:

2.7 "Cleaning collet and spindle caps" on page 35

Collet was cross-threaded

during last install

Replace spindle and collet:

2.13.9 "Spindle and spindle motor" on page 182

2.7 "Cleaning collet and spindle caps" on page 35

Spindle shaft doesn't rotate

Collet is in the open position Close collet first, then rotate the spindle shaft:

2.7 "Cleaning collet and spindle caps" on page 35

Debris around the spindle

shaft/collet/nozzle cap

Remove debris:

2.7 "Cleaning collet and spindle caps" on page 35

Damaged nozzle cap Replace nozzle cap:

2.7 "Cleaning collet and spindle caps" on page 35

Defective spindle Replace spindle:

2.13.9 "Spindle and spindle motor" on page 182

Defective spindle motor Replace spindle motor:

2.13.9 "Spindle and spindle motor" on page 182

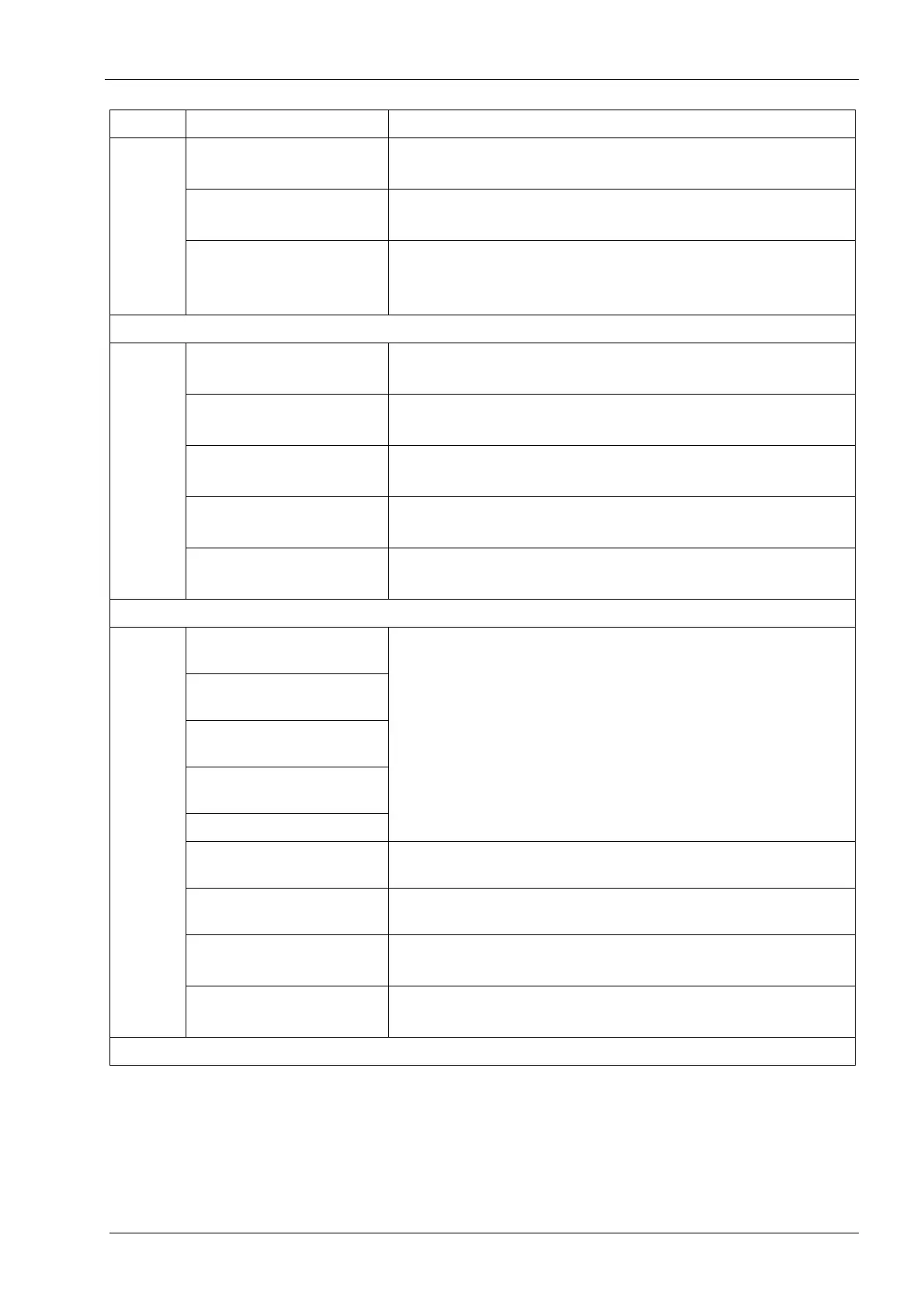

Tool walking

Debris in collet and/or

spindle shaft

Remove debris:

2.7 "Cleaning collet and spindle caps" on page 35

Debris on suction and/or

basket strainer

Debris on nozzle cap

nozzles

Debris in tubing/spindle

housing

Debris on tool shank

Milling without coolant

concentrate (water only)

Add coolant concentrate to fluid tank.

Tool usage is greater than

160 minutes

Replace tools at or before 160 minutes of usage.

Damaged collet Replace collet:

2.7 "Cleaning collet and spindle caps" on page 35

Defective spindle Replace spindle:

2.13.9 "Spindle and spindle motor" on page 182

Broken tool detection doesn't work

Symptom Problem Solution

Loading...

Loading...