31

2) Cylinder head ass’y

Disassembly

(1) Using a valve spring replacer, compress the valve spring

to remove the valve cotter, retainer, spring and valve.

(2) Remove the valve guide seal.

109Y

Inspection and service

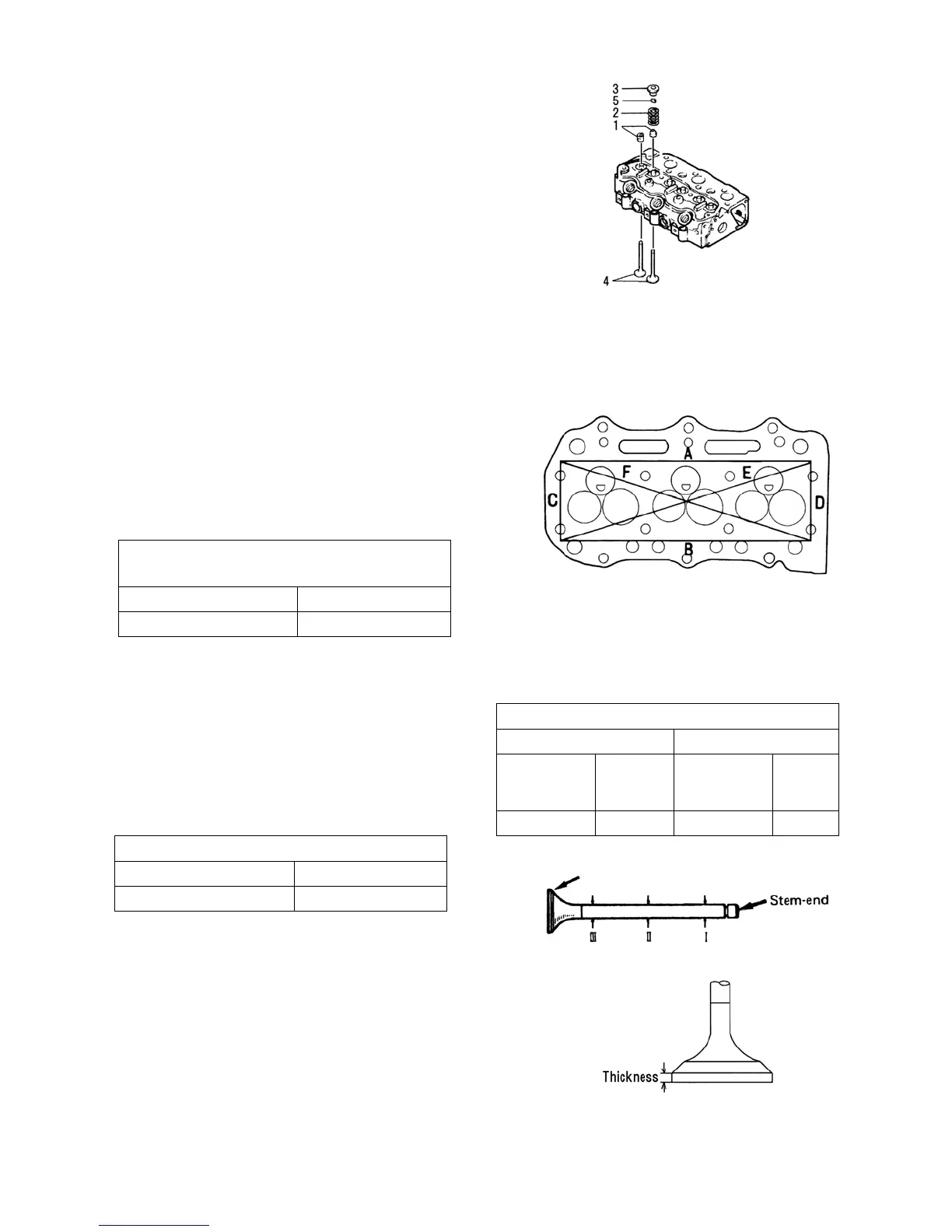

(1) Distortion of cylinder head bottom surface Apply a straight

edge to the bottom surface of the cylinder head, and insert a

thickness gauge at 6 points from A to F in the right figure

and measure distortion. If the distortion exceeds the repair

value, replace with new one.

Distortion at cylinder head bottom surface (mm)

Standard assembling value Repair value

Less than 0.05 More than 0.12

(2) Valve guide and valve stem

➀ Check the head and stem of each valve and replace if

burnout, wear or deformation is remarkable.

➁ Measure the outside diameter at the position I, II, and

III on the valve stem with a micrometer and replace if

the result is less than the service limit.

➂ Replace a valve if its head thickness is less than service

limit.

110Y

Wear of valve stem (mm)

Intake valve Exhaust valve

Standard

assembling

value

Service

limit

Standard

assembling

value

Service

limit

6.955 – 6.97 6.89 6.94 – 6.95 6.84

111Y

112Y

Valve head thickness (mm)

Standard assembling value Service limit

0.775 – 1.075 Less than 0.5

1. Valve guide seal

2. Spring

3. Retainer

4. Valve

5. Valve cotter

Loading...

Loading...